ធ្នូ . 06, 2024 11:38 Back to list

piston wiper seal

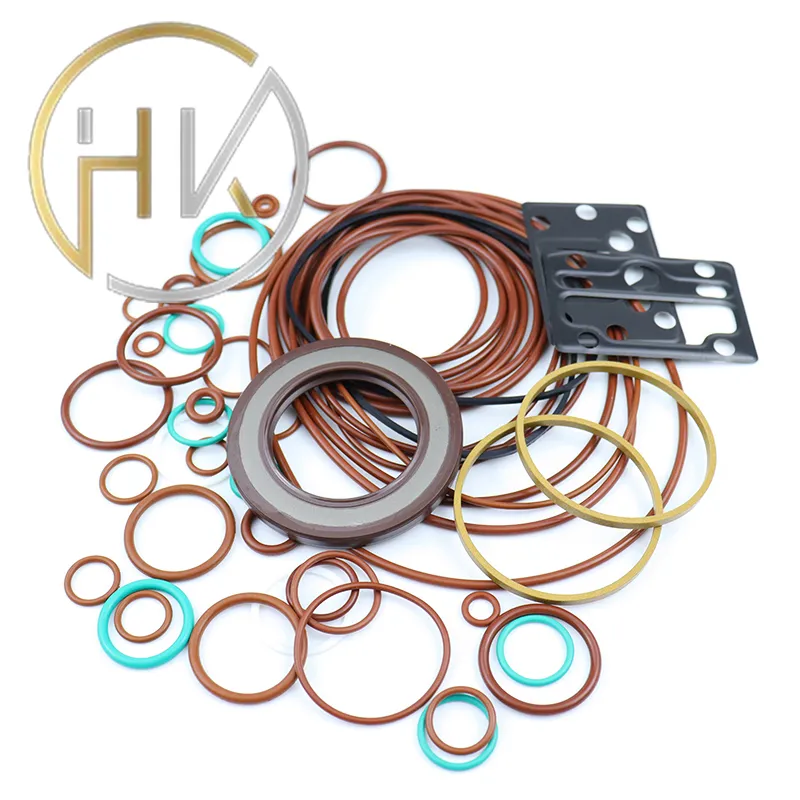

Understanding Piston Wiper Seals Function, Design, and Applications

Piston wiper seals are integral components commonly used in hydraulic and pneumatic systems to enhance the efficiency and longevity of machinery. They play a crucial role in preventing dust, dirt, and other contaminants from entering the cylinder, thereby safeguarding the piston and other internal components. Understanding their function, design, and applications is essential for anyone working with hydraulic systems.

Function of Piston Wiper Seals

The primary function of piston wiper seals is to keep contaminants out of the cylinder while allowing the piston to move freely. Without a wiper seal, dirt and debris could easily enter the system during operation, leading to increased wear and tear on the piston and cylinder surfaces. This can ultimately cause system failures and lead to costly repairs or replacements.

Wiper seals are designed to work in conjunction with other seals in the hydraulic or pneumatic system. While these other seals prevent fluid from leaking out, wiper seals ensure that no contaminants are able to breach the equipment's internal environment. By effectively blocking external particles, wiper seals help maintain the integrity of the hydraulic fluid, which is crucial for optimal system performance.

Design Considerations

The design of piston wiper seals is influenced by several factors, including the type of application, the operating environment, and the specific system requirements. Piston wiper seals are typically made from high-performance materials such as polyurethane, rubber, or elastomers, which provide excellent wear resistance, flexibility, and temperature tolerance.

One common design feature of piston wiper seals is the presence of a lip or sealing edge that contacts the piston rod. This lip is often angled to effectively scrape away contaminants while still maintaining a seal on the inside. The geometry of the wiper seal can also be tailored to accommodate various rod sizes and types of motion, such as linear or oscillating movements.

piston wiper seal

Additionally, many modern wiper seals are designed with an integrated spring mechanism, which helps maintain consistent contact with the piston rod. This ensures effective sealing throughout the range of motion, even when the rod undergoes changes in speed or direction.

Applications

Piston wiper seals find applications across various industries, including automotive, manufacturing, aerospace, and construction. In automotive applications, they are essential in power steering systems, brakes, and shock absorbers, where they contribute to maintaining fluid integrity and system responsiveness.

In manufacturing and construction, wiper seals are critical in hydraulic machinery, such as excavators and forklifts. These environments often expose machinery to significant levels of dust and debris, making robust sealing solutions necessary for ensuring reliable operation.

The aerospace industry also relies on piston wiper seals for landing gear and hydraulic systems on aircraft, where rigorous safety standards and operational reliability are paramount. The ability of these seals to withstand extreme conditions, such as high altitude and varying temperatures, makes them invaluable in aviation applications.

Conclusion

Piston wiper seals are vital components in hydraulic and pneumatic systems, offering protection against contaminants and extending the life of machinery. Their design and functionality are key to ensuring the efficiency and reliability of various industrial applications. As technology advances, the materials and designs of these seals continue to evolve, promising even greater levels of performance and protection in the future.

Understanding the importance of piston wiper seals can help engineers and technicians make informed decisions regarding equipment maintenance and selection, ultimately enhancing the performance of their systems. Whether in automotive technology, manufacturing, or aerospace, the role of piston wiper seals cannot be overstated, as they contribute significantly to the operational success of machinery and equipment across diverse fields.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories