តុលា . 16, 2024 18:54 Back to list

Understanding the Functionality of Oil Wiper Rings in Engine Performance

Understanding Oil Wiper Rings Function, Types, and Importance

Oil wiper rings play a crucial role in the overall performance and efficiency of engines, particularly in internal combustion engines. These components are designed to control the oil film on cylinder walls, preventing excessive oil consumption while ensuring optimal lubrication and sealing during the combustion process. This article delves into the significance of oil wiper rings, their types, and their impact on engine efficiency.

What are Oil Wiper Rings?

Oil wiper rings, sometimes referred to as oil control rings, are a specific type of piston ring designed to regulate the flow of oil between the piston and the cylinder walls. They serve two primary functions wiping excess oil from the cylinder wall to minimize oil consumption and ensuring a proper seal between the piston and the cylinder, thus preventing the entry of oil into the combustion chamber. Effective oil wiper rings are vital for maintaining the performance of an engine, as they directly influence oil use, emissions, and engine life.

How Do Oil Wiper Rings Work?

The operation of oil wiper rings is instrumental in maintaining engine performance. Positioned in the piston ring assembly, the oil wiper ring is typically located below the compression rings. As the piston moves up and down within the cylinder, the wiper ring wipes excess oil off the cylinder walls, directing it back down into the oil sump. This action helps maintain an optimum oil film thickness on the cylinder wall, ensuring that the rings have adequate lubrication to function effectively.

The design of oil wiper rings often incorporates a slight bevel, which enhances their capability to wipe oil efficiently

. As the ring traverses the cylinder walls, the wedge-shaped design allows it to scrape excess oil while leaving a thin layer for lubrication, effectively balancing oil control and engine performance.Types of Oil Wiper Rings

Oil wiper rings can be classified into several types based on their material, design, and functionality

1. Conventional Wiper Rings These are made from cast iron or steel and exhibit good wear resistance. Their primary function is to control oil and maintain a seal.

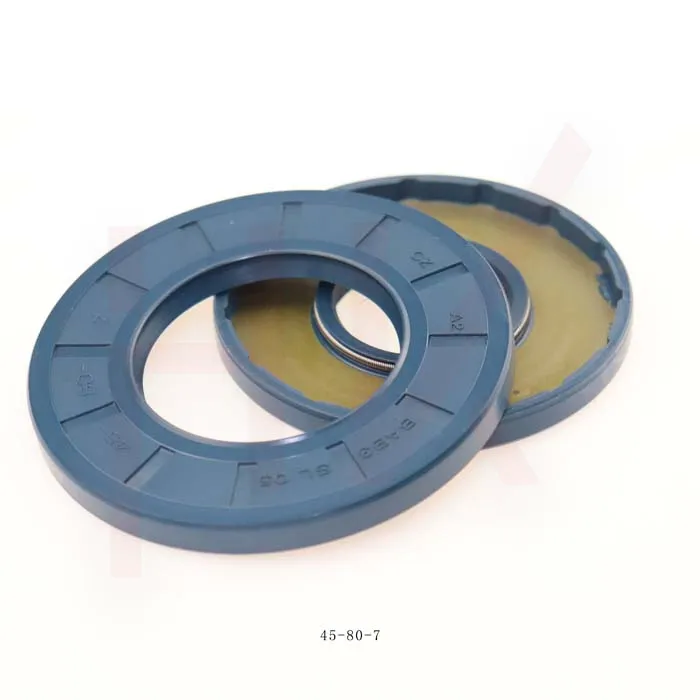

oil wiper ring

2. Spring-loaded Wiper Rings These rings include a spring mechanism that provides additional pressure against the cylinder wall, enhancing oil control and sealing capabilities. They are particularly beneficial in high-performance engines.

3. Thermal Wiper Rings Designed to expand and contract with temperature fluctuations, these rings are employed in applications where thermal variations significantly impact engine operation.

4. Composite Wiper Rings Made from advanced materials, these rings offer improved wear resistance and lower friction, making them suitable for modern engine designs that emphasize efficiency and reduced emissions.

Importance of High-Quality Oil Wiper Rings

High-quality oil wiper rings contribute significantly to overall engine efficiency and longevity. Poor-quality or worn-out wiper rings can lead to several problems, including

- Increased Oil Consumption Ineffective wiper rings can allow excessive oil to enter the combustion chamber, resulting in higher oil consumption and potentially leading to engine damage.

- Emissions Issues Burnt oil can increase harmful emissions, failing to meet regulatory standards and impacting environmental efforts.

- Reduced Engine Performance When oil control is compromised, it can lead to poor combustion efficiency, reduced power output, and overall engine inefficiency.

Conclusion

In summary, oil wiper rings are essential components in internal combustion engines, playing a vital role in oil control and engine performance. Understanding the types and functions of oil wiper rings can help engineers and vehicle owners appreciate their significance in maintaining engine efficiency and longevity. Investing in high-quality wiper rings is crucial for anyone looking to optimize their engine's performance, reduce environmental impact, and prolong engine life. As technology advances, the design and materials used in oil wiper rings will continue to evolve, further enhancing engine efficiency and performance in the automotive industry.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories