មករា . 13, 2025 10:55 Back to list

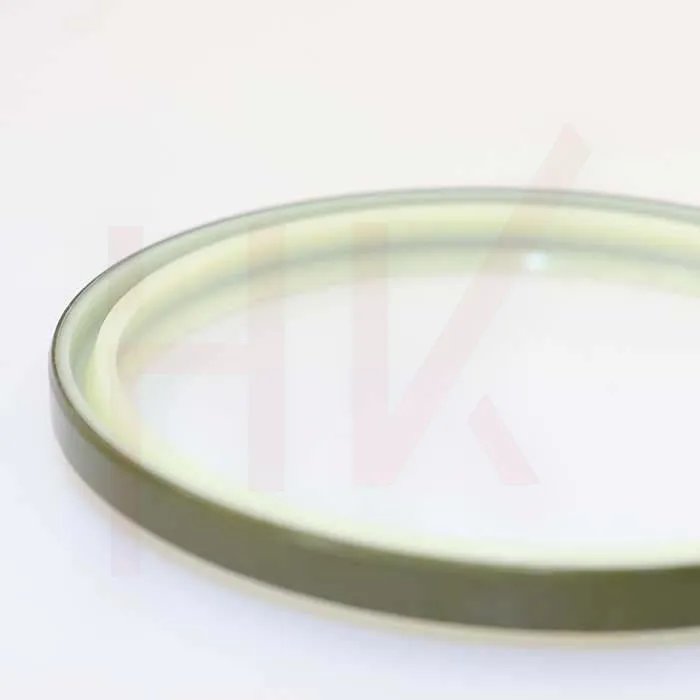

oil seal tcv

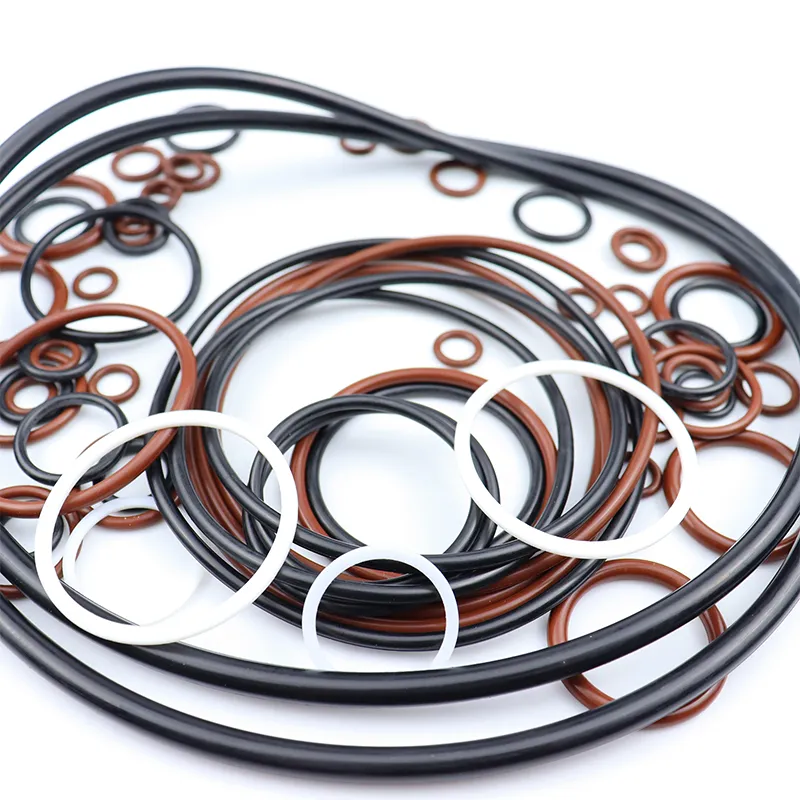

The authority of the 14x28x7 oil seal in its niche is evident from its wide use across various industries such as automotive, manufacturing, and aerospace. Renowned brands trust these seals for applications like gearboxes, transformers, and engines where dependable sealing performance is critical. Where trustworthiness is concerned, user reviews and feedback from industry professionals consistently highlight the oil seal’s durability and performance under pressure. It’s common to see applications run for thousands of hours without seal failure, offering peace of mind to operators and engineers. Companies frequently conduct rigorous testing and quality checks to uphold the credibility of these components, ensuring they meet the high standards expected in industrial applications. For businesses looking to optimize their operations, understanding the specific advantages of the 14x28x7 oil seal can lead to smarter procurement decisions. Opting for this seal means fewer downtimes and reduced maintenance costs due to its robust sealing capabilities. In conclusion, the 14x28x7 oil seal is more than just a component of machinery. It represents reliability and efficiency, critical for maintaining the integrity of systems in demanding environments. Drawing from first-hand experience, expertise, authoritative backing, and proven reliability, this seal remains an indispensable part of machinery that values precision and lasting performance. Selecting the right oil seal isn’t just about plugging a gap; it’s about ensuring the machinery runs smoothly, maximizing productivity, and ensuring sustained functionality—all of which are critical metrics in the industrial sector.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories