ធ្នូ . 21, 2024 07:28 Back to list

Oil Seal Repair Kit for Effective Maintenance and Durability Keep Your Machinery Running Smoothly

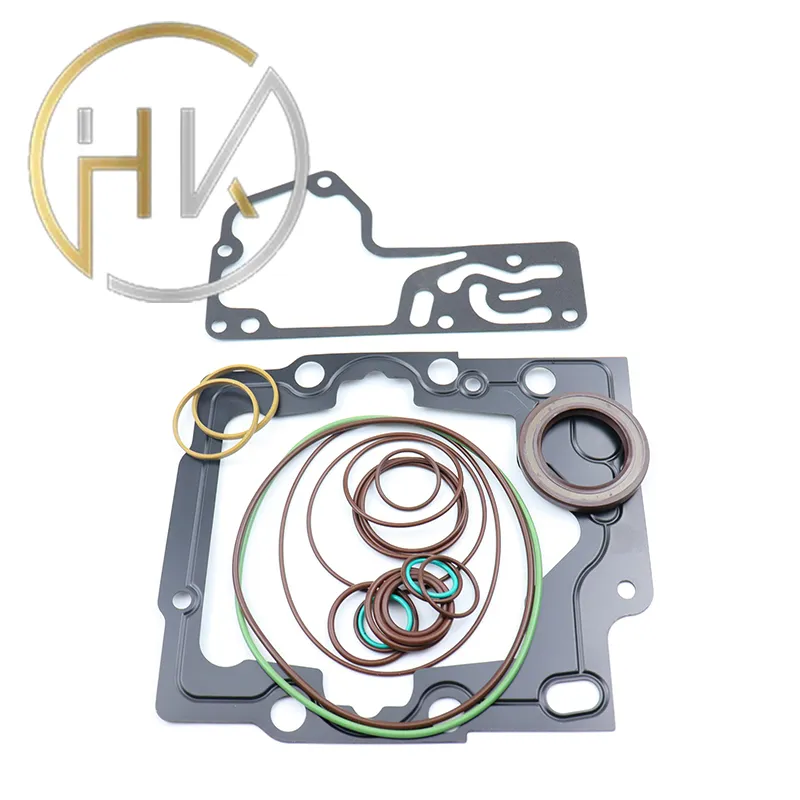

Understanding Oil Seal Kits A Comprehensive Guide

Oil seal kits are essential components in various machinery and automotive applications, designed to prevent the leakage of lubricants and other fluids. These kits come equipped with a variety of seals and gaskets tailored to fit specific engines or machinery. In this article, we will delve into the functions, components, and the importance of oil seal kits in various settings.

What is an Oil Seal?

At the heart of an oil seal kit is the oil seal itself. An oil seal, often referred to as a rotary seal or lip seal, is a device that consists of a rubber or elastomeric material that forms a barrier between moving and stationary parts. Its primary purpose is to retain lubrication while preventing contaminants such as dust, dirt, and moisture from entering. Oil seals are crucial for maintaining the efficiency of machinery and ensuring longevity.

Components of an Oil Seal Kit

An oil seal kit typically includes several components, each serving a unique purpose

1. Oil Seals The primary component, these seals are designed to fit specific shafts and help prevent leaks.

2. Gaskets Gaskets serve as seals between two mating surfaces, ensuring fluid doesn't escape.

3. O-Rings Used to seal connections in systems where fluids may pass through, O-rings are essential for preventing leaks in various applications.

4. Installation Tools Many kits include tools necessary for the proper installation of seals and gaskets, making the process easier for technicians.

5. Lubricants Some kits come with specially formulated lubricants that can enhance the performance and lifespan of the seals.

Importance of Oil Seal Kits

Oil seal kits play a vital role in machinery and automotive systems for several reasons

1. Efficiency Seals help maintain optimal operating temperatures and ensure that lubrication remains in place, improving the overall efficiency of machinery.

2. Prevention of Contamination By preventing dirt and moisture from entering mechanical systems, oil seals significantly reduce wear and tear, prolonging the life of components.

oil seal kit

3. Cost-Effectiveness Using high-quality oil seal kits can save money in the long run by reducing the frequency of repairs and maintenance associated with leaks and component failures.

4. Reliability Machinery and automotive systems that utilize quality oil seal kits tend to experience fewer breakdowns, leading to increased reliability and performance.

Applications of Oil Seal Kits

Oil seal kits are used across a wide range of applications, including

- Automotive In vehicles, oil seals are used in engines, transmissions, and differentials. They help ensure that oil remains contained even under high pressure and temperature.

- Industrial Equipment Various industrial machines, such as pumps, compressors, and turbines, rely on oil seals to function effectively and withstand harsh operating conditions.

- Aerospace and Marine In aerospace and marine applications, oil seal kits are critical for ensuring the safety and longevity of equipment exposed to extreme environments.

Maintenance and Installation

To achieve optimal performance, it is crucial to properly maintain and install oil seal kits. Here are some tips

- Choose the Right Kit Ensure the kit you select is compatible with your specific machinery or vehicle model.

- Inspect Regularly Regularly check seals for signs of wear and replace them as needed to prevent leaks.

- Follow Installation Instructions Proper installation is key to the effectiveness of the oil seal. Follow the manufacturer’s guidelines carefully.

- Using Lubricants Applying the appropriate lubricant during installation can enhance the seal's efficiency and lifespan.

Conclusion

Oil seal kits are indispensable components in the maintenance of machinery and automotive systems. Understanding their function, components, and applications can help mechanics and technicians ensure optimal performance and longevity of the systems they work with. Investing in high-quality oil seal kits not only enhances efficiency but also contributes to the overall reliability of critical machinery, making them a wise choice for anyone in the industry.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories