ធ្នូ . 05, 2024 05:10 Back to list

Pump Oil Seals for Effective Leakage Prevention and Performance Enhancement Solutions

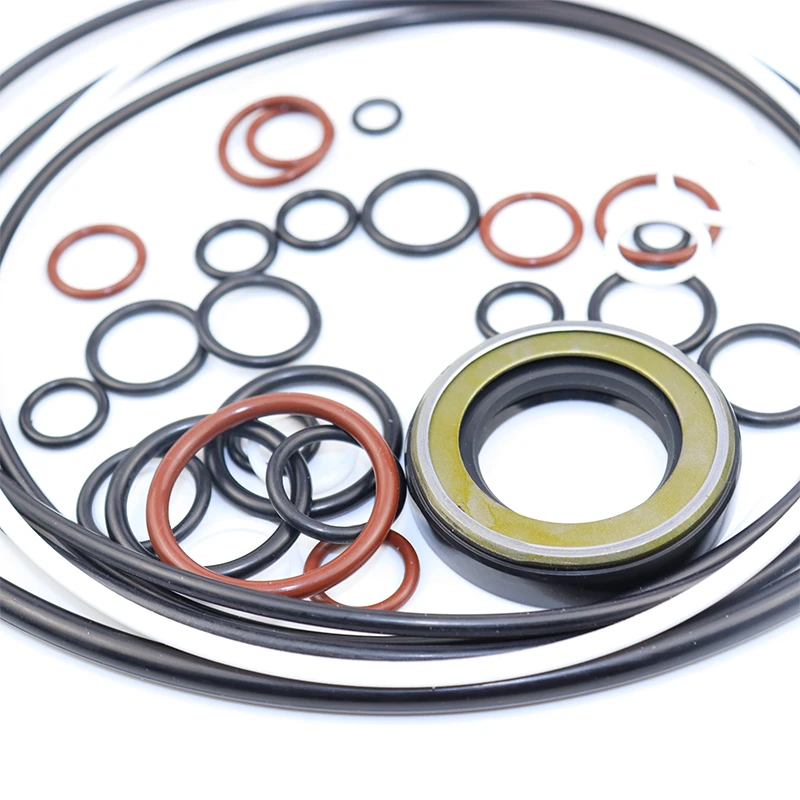

Oil Seals for Pumps Essential Components for Performance and Longevity

Oil seals, also known as lip seals or rotary seals, play a vital role in the operation of pumps across various industries. These components are crucial in preventing the leakage of lubricants and hydraulic fluids, ensuring that pumps operate efficiently and reliably. The design and functionality of oil seals can significantly influence a pump's performance, longevity, and maintenance needs.

Understanding Oil Seals

An oil seal is a device used to seal rotating shafts and prevent the escape of lubricants while keeping contaminants such as dirt, dust, and moisture from entering the machinery. Oil seals come in different shapes and sizes, designed to fit various applications and environmental conditions. Typically, they consist of a flexible lip that exerts pressure against the shaft, creating a barrier to fluid leakage.

Types of Oil Seals

There are several types of oil seals available for different applications, including

1. Single Lip Seals These are the most common type, featuring one sealing lip that makes contact with the shaft. They are ideal for low-pressure applications.

2. Double Lip Seals These seals have two lips, providing extra protection against leaks and contamination. They are suitable for more demanding environments, such as those with high pressure or the potential for exposure to debris.

3. Spring-Loaded Seals These seals incorporate a spring mechanism that maintains consistent contact with the shaft, compensating for wear and thermal expansion. This design enhances the seal's performance and lifespan.

4. Specialty Seals Manufacturers also create seals made from specific materials designed to withstand extreme temperatures, chemicals, and environmental conditions. These specialty seals are crucial for pumps used in industries like oil and gas, chemicals, and food processing.

The Importance of Oil Seals in Pumps

1. Prevention of Fluid Leakage One of the primary functions of oil seals is to prevent the leakage of lubricants from within the pump. Leakage not only wastes valuable resources but can also lead to inefficiencies in the pumping system.

oil seal for pump

2. Protection from Contaminants Oil seals help keep contaminants such as dirt and moisture from entering the pump. The presence of these particles can cause wear and tear on internal components, leading to premature failure.

3. Enhanced Performance and Efficiency By minimizing leaks and preventing contamination, oil seals contribute to the overall efficiency of pumps. A well-sealed pump operates more effectively, reducing energy consumption and operational costs.

4. Reduced Maintenance Needs With effective seals in place, the need for frequent maintenance is diminished. This not only saves time and money but also ensures that the pumping system remains operational for longer periods.

5. Extended Equipment Lifespan Using the correct oil seals can significantly extend the lifespan of pumping equipment. By preventing damage from leakage and contamination, oil seals help maintain the integrity of internal components.

Selecting the Right Oil Seal for Pumps

Choosing the right oil seal for a pump involves considering several factors

- Shaft Size and Speed The dimensions and rotational speed of the shaft will dictate which type of oil seal is appropriate.

- Operating Environment The temperature, pressure, and potential exposure to chemicals or contaminants must be assessed to select a seal material that will perform reliably.

- Compatibility with Lubricants Ensure that the seal material is compatible with the lubricants used in the pump, as certain chemicals can degrade some seal materials.

- Application Type Different applications may require specialized seals, so understanding the specific needs of the pump is crucial.

Conclusion

Oil seals are essential components for maintaining the performance and longevity of pumps. They provide critical barriers against fluid leakage and contamination, ensuring that pumps operate efficiently and effectively. By selecting the right oil seal for a specific application and environmental condition, users can enhance pump reliability, reduce maintenance needs, and extend the operational lifespan of their equipment. Investing in high-quality oil seals is a proactive approach that can lead to significant savings and improved performance in the long run. Whether in industrial settings, automotive applications, or household use, the importance of oil seals cannot be understated.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories