ធ្នូ . 10, 2024 15:57 Back to list

hydraulic oil seal sizes

Understanding Hydraulic Oil Seal Sizes A Comprehensive Guide

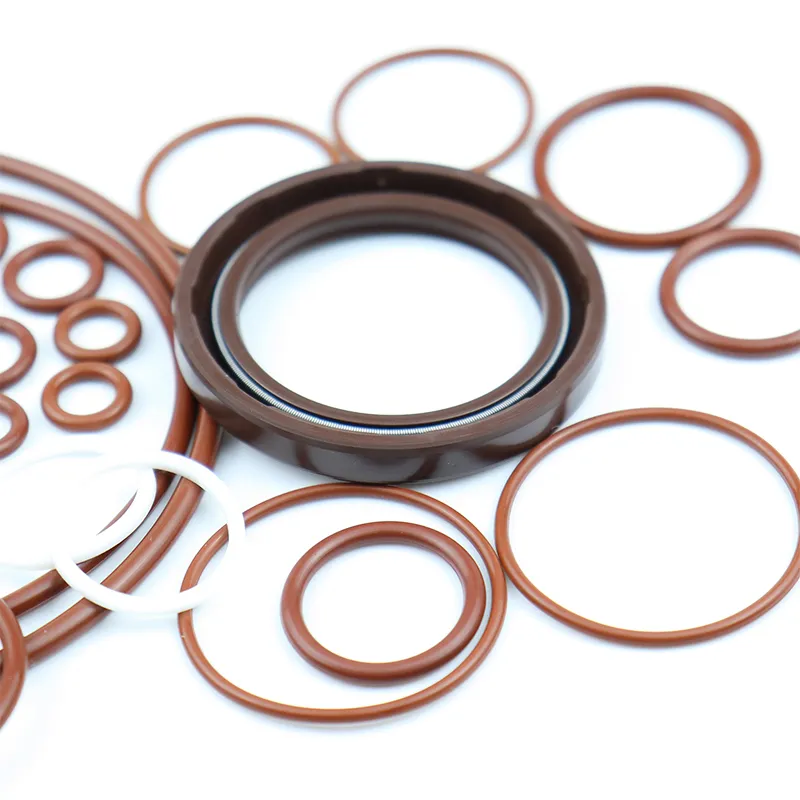

Hydraulic systems are critical components in various industrial applications, from construction machinery to aerospace engineering. One vital component that ensures the efficient operation of these systems is the hydraulic oil seal. These seals prevent the leakage of hydraulic fluid and contaminants, thereby maintaining pressure and ensuring the longevity of equipment. Understanding hydraulic oil seal sizes is essential for effective maintenance and replacement, and this article will explore the importance, sizing, and selection process of hydraulic oil seals.

The Importance of Hydraulic Oil Seals

Hydraulic oil seals serve several essential functions within a hydraulic system. Primarily, they prevent the escape of hydraulic fluids under pressure, which is crucial for the system's performance. Leakage not only results in inefficiency but also can lead to environmental hazards, safety issues, and costly repairs. Additionally, these seals protect the internal components of hydraulic systems from dirt, dust, and other contaminants that can cause wear and tear.

Selection of the correct hydraulic oil seal size is vital for effective sealing. An improperly sized seal may lead to inadequate sealing, resulting in leaks or premature failure of the hydraulic system. Therefore, understanding the specific size requirements of these seals is paramount.

Understanding Seal Sizes

Hydraulic oil seals come in various sizes, and the specific dimensions depend on the application in which they will be used. These dimensions include

1. Outer Diameter (OD) This is the diameter of the seal's outer edge, which fits into the housing. The outer diameter is crucial for ensuring that the seal fits snugly into the intended groove.

2. Inner Diameter (ID) The inner diameter is the diameter of the hole through which the hydraulic shaft passes. This measurement must be precise, as any mismatch can lead to significant leaks.

3. Width (W) The width of the seal is important for providing a proper contact surface. A seal that is too thin may fail to create an effective seal, while one that is too thick could lead to excessive friction and wear.

4. Material Considerations While not a size measurement, the material of the hydraulic oil seal affects its performance. Rubber, polyurethane, and PTFE (Teflon) are common materials, each with different resistance to temperature, pressure, and chemical exposure.

How to Measure Seal Sizes

hydraulic oil seal sizes

To order the correct hydraulic oil seal sizes, accurate measurements must be taken. Here’s how to measure effectively

1. Remove the Old Seal Carefully extract the existing seal from its groove using appropriate tools to avoid damaging the housing or shaft.

2. Measure the ID Use calipers to measure the inner diameter of the seal. Measure at multiple points to ensure accuracy, as the seal may wear unevenly.

3. Measure the OD Next, measure the outer diameter using calipers, ensuring you are measuring at the widest point.

4. Measure the Width Finally, measure the width of the seal, making sure to perform this measurement on the intact seal without squeezing it.

5. Record Any Additional Specifications As mentioned earlier, consider the seal material and any specific features (like lip design) that might be important for your application.

Selecting the Right Seal

After gathering all necessary measurements, the next step is selecting the appropriate hydraulic oil seal. Be sure to consult manufacturer catalogs, as they provide detailed specifications and alternatives based on the sizes measured.

It’s also essential to consider the operating environment. If the system operates in extreme temperatures or pressures, choosing a seal material that can withstand those conditions is critical. In some cases, customization may be necessary, and consulting with seal manufacturers can provide insights into tailored solutions.

Conclusion

In conclusion, understanding hydraulic oil seal sizes is fundamental for anyone involved in maintaining or repairing hydraulic systems. Proper sealing can make the difference between a well-functioning system and one that is prone to leaks and failures. By accurately measuring seal dimensions and understanding material properties, operators can ensure the longevity and efficiency of their hydraulic machinery. Remember, taking the time to select the right seal can save you time, money, and resource—in the long run, making hydraulic systems more reliable and efficient.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories