មករា . 19, 2025 03:04 Back to list

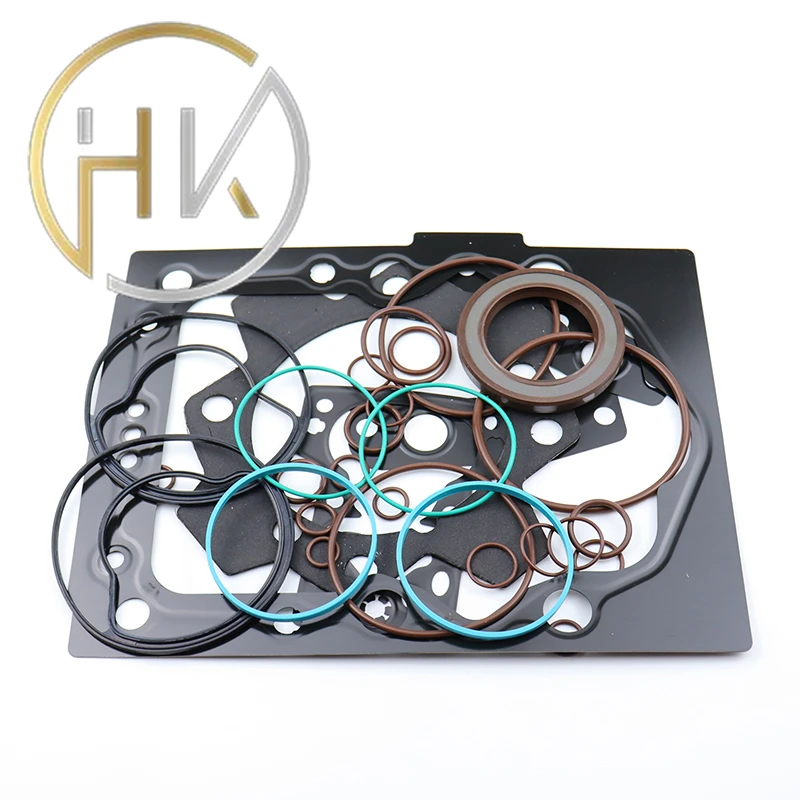

hydraulic floor jack repair kit

Authoritativeness in this domain is built from reliable sources that back their advice with data-driven guidance. Reputable manufacturers of hydraulic floor jack repair kits often provide detailed manuals and instructions, which embody a level of trust supported by years of engineering experience. Engaging with these resources can help demystify the repair process, offering clarity on potential challenges and solutions. Accessing such authoritative content also assures that you receive updated knowledge that reflects the latest advancements in hydraulic technology. Trustworthiness is critical when selecting both the kit and approach. Consumers should seek repair kits from recognized brands known for their durable and superior products. Reviews from industry professionals can offer guidance, confirming that the kits have been tested under strenuous conditions and meet high performance standards. Cultivating trust includes not only the products but also those who share their cumulative repair experiences online. Following the community discussions where expert advice and firsthand repair experiences are exchanged can significantly boost confidence in one's repair efforts. In conclusion, hydraulic floor jack repair kits provide an invaluable resource for maintaining the functionality of these essential tools. By leveraging a combination of expert knowledge, firsthand experience, authoritative resources, and trustworthy products, you can not only repair your hydraulic floor jack effectively but can extend its life significantly. Through informed choices and careful maintenance, your floor jack will continue to serve its purpose reliably, ensuring that your workspace remains efficient and safe for all your heavy-lifting needs.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories