តុលា . 30, 2024 16:29 Back to list

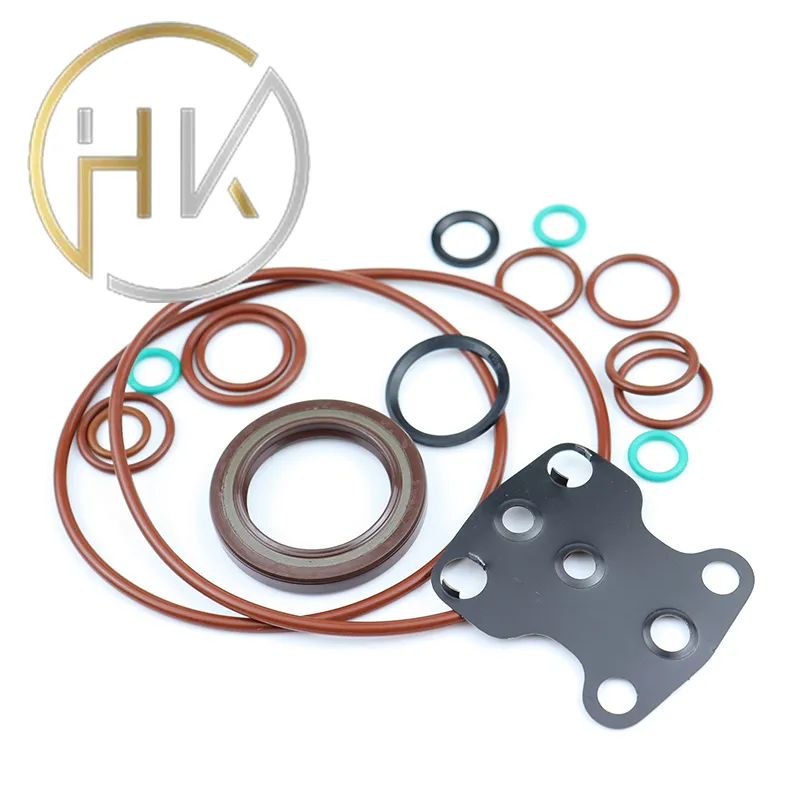

hydraulic cylinder seal repair

Hydraulic Cylinder Seal Repair A Comprehensive Guide

Hydraulic cylinders play a crucial role in various industrial and mechanical applications, providing the necessary force for lifting, pushing, or pulling. However, over time, the seals within these cylinders can wear out due to constant pressure, contamination, and environmental factors. This article delves into the importance of hydraulic cylinder seal repair and outlines the steps involved in the process.

Understanding the Importance of Seals

Seals in hydraulic cylinders prevent fluid leakage and maintain pressure, allowing the system to operate effectively. A failing seal can lead to numerous issues, including reduced efficiency, increased operating costs, and even catastrophic failures. Regular inspection and timely repair of seals can prevent more significant problems down the line, ensuring the safety and longevity of your hydraulic systems.

Signs of Seal Failure

Detecting seal failure early is crucial for minimizing downtime and repair costs. Common signs of a faulty seal include

1. Fluid Leakage This is the most obvious sign. If you notice hydraulic fluid pooling around the cylinder, it's time to assess the seals. 2. Decreased Performance A sudden drop in performance, such as slow actuating times, could indicate seal wear or damage.

3. Increased Noise Unusual sounds during operation, like grinding or hissing, can suggest internal issues related to seal failure.

Steps for Seal Repair

hydraulic cylinder seal repair

Repairing seals in hydraulic cylinders involves several key steps. Here’s a concise guide to performing the repair effectively.

1. Disassemble the Cylinder First, isolate the hydraulic system by shutting off the power supply and relieving pressure. Carefully remove the cylinder from its mounting, noting the orientation and arrangement of components.

2. Examine the Components Inspect the piston, rod, and cylinder bore for signs of wear or damage. Any imperfections here may necessitate further repair or replacement beyond just the seals.

3. Remove the Old Seals Take out the worn seals using appropriate tools, being careful not to scratch or damage the cylinder surfaces. Take note of the seal type and dimensions for accurate replacement.

4. Prepare for New Seals Clean the sealing surfaces thoroughly to remove any debris or old seal material. This ensures proper seating for the new seals.

5. Install New Seals Select the correct replacement seals and install them carefully into their designated grooves. Make sure they are appropriately aligned to avoid leaks.

6. Reassemble the Cylinder Once the new seals are in place, reassemble the cylinder components, ensuring everything is aligned correctly. Tighten bolts and fittings to the manufacturer’s specifications.

7. Test the System After reassembly, reconnect the cylinder to the hydraulic system, restore the fluid levels, and conduct a test run. Check for any signs of leaks, and ensure the cylinder operates smoothly.

Conclusion

Routine maintenance and timely repair of hydraulic cylinder seals can significantly enhance the longevity and efficiency of hydraulic systems. By following the steps outlined above, you can tackle seal repairs with confidence, ensuring your equipment runs seamlessly. Whether you’re a seasoned technician or a novice, understanding the intricacies of hydraulic cylinder seal repair is essential for maintaining optimal performance in hydraulic systems.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories