វិច្ឆិកា . 04, 2024 00:58 Back to list

hydraulic cylinder seal kits

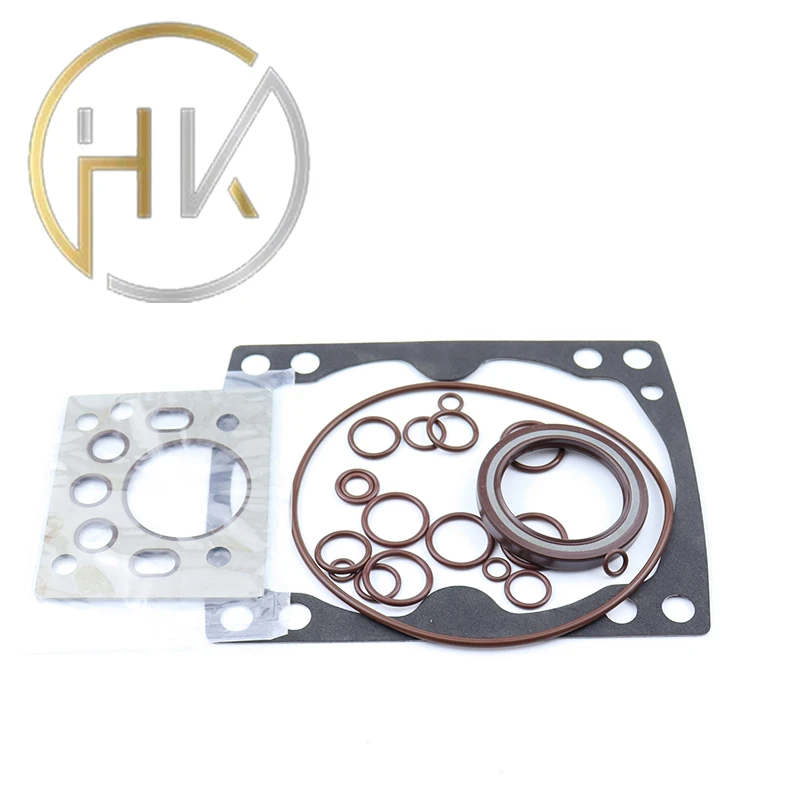

Understanding Hydraulic Cylinder Seal Kits An Essential Component for Performance

Hydraulic systems play a crucial role in various industries, from construction and manufacturing to automotive and aerospace. At the heart of these systems lies the hydraulic cylinder, which relies on seal kits to maintain efficiency and functionality. Understanding hydraulic cylinder seal kits is essential for anyone involved in machinery maintenance and repair.

Hydraulic cylinder seal kits are composed of various seals and components designed to prevent fluid leakage, ensure proper pressure retention, and protect the internal workings of the hydraulic cylinder. These kits typically include O-rings, piston seals, rod seals, and backup rings, each serving a specific function in maintaining the integrity of the hydraulic system.

One of the primary components, the O-ring, provides a dependable leak-proof seal between static and dynamic surfaces. The O-ring’s material—often rubber or polyurethane—ensures flexibility and resilience, allowing it to compress and adapt to the varying pressures within the hydraulic system. Piston seals, on the other hand, are crucial for maintaining pressure and controlling fluid flow within the cylinder. They are designed to withstand high pressures and temperatures, ensuring long-lasting performance.

hydraulic cylinder seal kits

Rod seals function to keep hydraulic fluid contained within the cylinder while preventing contaminants from entering the system. This is vital for protecting the cylinder’s internal surfaces from damage and wear. Backup rings are often used alongside other seals to provide added support and prevent extrusion, especially in high-pressure applications.

Choosing the right seal kit is vital for optimal hydraulic cylinder performance. Factors such as operating pressure, temperature, fluid compatibility, and environmental conditions all influence the selection process. High-quality seal kits that are specifically tailored to the application can dramatically improve the lifespan of the hydraulic cylinder, reduce maintenance costs, and enhance overall system reliability.

Regular inspection and maintenance of hydraulic cylinder seal kits are equally important. Over time, seals can wear out due to heat, pressure, and contamination, leading to potential leaks and system failures. Routine checks enable operators to identify wear early, replacing seals as needed to avoid costly downtime or catastrophic failures.

In conclusion, hydraulic cylinder seal kits are an integral part of hydraulic systems, ensuring the efficient operation and longevity of machinery. By understanding their components and functions, as well as maintaining them effectively, operators can enhance the performance and reliability of their hydraulic equipment, ultimately leading to increased productivity and reduced costs in various industrial applications.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories