ធ្នូ . 29, 2024 11:32 Back to list

Hydraulic Cylinder Repair Kits for Efficient Maintenance and Performance Improvement

Understanding Hydraulic Cylinder Rebuild Kits

Hydraulic cylinders are critical components in various machinery and equipment, performing essential tasks such as lifting, pushing, and pulling. These hydraulic systems are trusted for their durability and efficiency. However, like all mechanical parts, they can wear out over time due to constant stress, exposure to contaminants, and improper maintenance. When a hydraulic cylinder begins to show signs of wear—such as leaks or reduced performance—a rebuild kit is often the most effective solution to restore its function without the cost of a complete replacement.

What is a Hydraulic Cylinder Rebuild Kit?

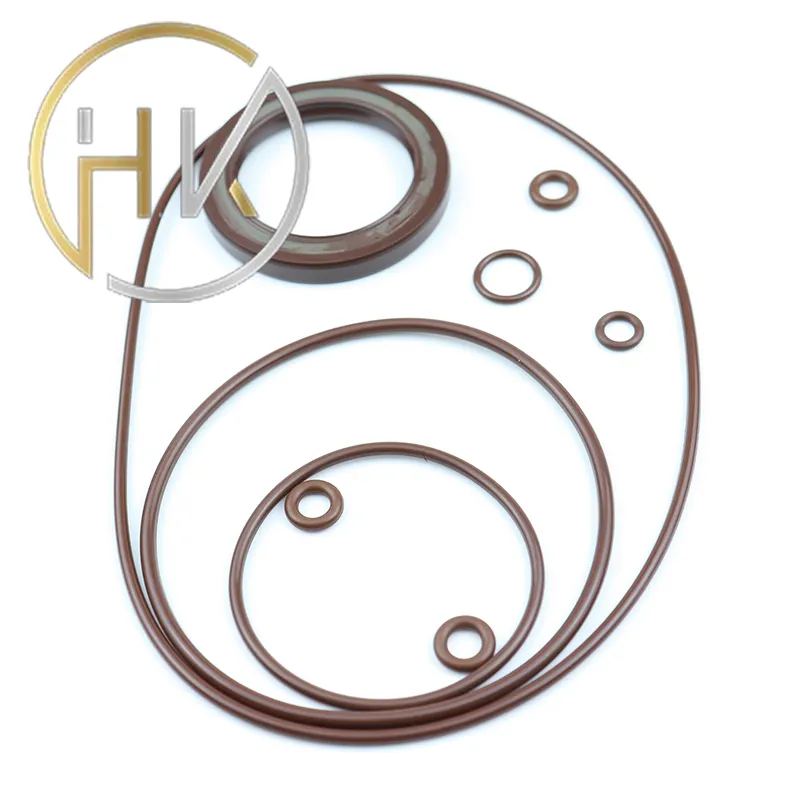

A hydraulic cylinder rebuild kit typically contains all the necessary components to restore a hydraulic cylinder to its original condition. These kits usually include seals, O-rings, backup rings, wipers, and sometimes even rods or other essential parts depending on the hydraulic cylinder's design and application. The purpose of these components is to replace worn or damaged parts that can lead to failures or inefficiencies.

Benefits of Using a Rebuild Kit

1. Cost-Effective Purchasing a rebuild kit is often significantly less expensive than buying a brand-new hydraulic cylinder. For many businesses, this cost-saving is crucial, especially when dealing with multiple machines.

2. Enhanced Performance By replacing worn-out components, a rebuild can restore the hydraulic cylinder's efficiency and functionality, thus prolonging the life of the machine.

3. Environmental Consideration Rebuilding instead of replacing is a more sustainable option, as it reduces waste and the demand for new materials.

hydraulic cylinder rebuild kits

Choosing the Right Rebuild Kit

When selecting a hydraulic cylinder rebuild kit, it is vital to consider several factors to ensure compatibility and effectiveness

- Manufacturer and Model Always check that the rebuild kit is compatible with the specific manufacturer and model of your cylinder. This information can often be found in the equipment’s manual or on the manufacturer's website.

- Component Quality Not all rebuild kits are created equal. Look for kits that use high-quality materials, such as Viton or polyurethane seals, which offer better resistance to heat and chemicals.

- Complete Kits Verify that the kit includes all essential components to complete the rebuild. Kits lacking vital parts may lead to further disruptions and additional costs.

Rebuilding Process

The rebuilding process typically starts with disassembling the hydraulic cylinder. Users should take care to document the disassembly process to facilitate reassembly. Once disassembled, existing seals can be removed, and the cylinder should be thoroughly cleaned to eliminate any dirt or contaminants. After cleaning, new components from the rebuild kit can be installed as per the instructions provided. Finally, the cylinder is reassembled, and it’s essential to test the system at low pressure before returning it to full operation.

Conclusion

Hydraulic cylinder rebuild kits are a practical solution for companies looking to maintain their hydraulic systems economically and effectively. With a proper rebuild, organizations can improve equipment performance, reduce costs, and minimize waste. By understanding the components and the process involved, operators can ensure their hydraulic cylinders remain efficient and reliable, thus extending the lifespan of their machinery and enhancing overall productivity.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories