កញ្ញា . 10, 2024 22:14 Back to list

hydraulic cylinder repair seal kit

Understanding Hydraulic Cylinder Repair Seal Kits

Hydraulic systems are vital components in many industrial and machinery applications, allowing for the efficient and powerful movement of heavy loads. A key part of these systems is the hydraulic cylinder, which utilizes fluid pressure to generate linear motion. However, over time, hydraulic cylinders can experience wear and tear, leading to leaks and a decline in performance. This is where hydraulic cylinder repair seal kits come into play.

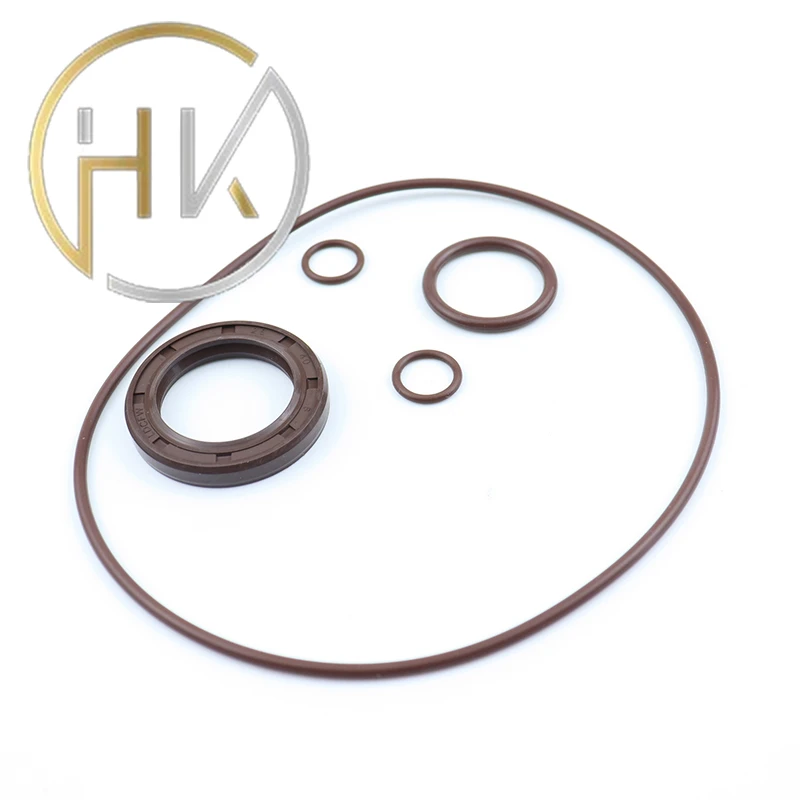

Hydraulic cylinder repair seal kits are essential for maintaining the functionality and efficiency of hydraulic cylinders. These kits typically include a variety of seals, O-rings, and other components specifically designed to replace worn or damaged parts within the cylinder. Regular maintenance and timely repairs can prevent costly downtime and extend the lifespan of the equipment.

Key Components of Hydraulic Cylinder Repair Seal Kits

1. Seals and Rod Seals These are critical components that prevent hydraulic fluid from leaking out of the cylinder. They fit tightly around the piston rods and ensure that the fluid pressure is maintained within the cylinder. Common types include U-cups, square rings, and lip seals.

2. O-Rings O-rings are used to create a seal at various points in the hydraulic system, preventing leaks between two surfaces. They are essential in maintaining pressure within the hydraulic circuit.

3. Backup Rings These are used in conjunction with O-rings to provide additional support and prevent extrusion under high pressures. They help to prolong the life of the O-rings and overall sealing components.

hydraulic cylinder repair seal kit

4. Guide Rings These components help to maintain alignment and reduce wear between moving parts. They are crucial in ensuring smooth operation, especially in high-load applications.

5. Dust Seals Dust seals protect the internal components from external contaminants, such as dirt and debris. This is vital for maintaining a clean hydraulic system and preventing premature wear.

Benefits of Using Repair Seal Kits

Utilizing hydraulic cylinder repair seal kits offers numerous benefits. First and foremost, they provide a cost-effective solution for repairs. Buying a complete kit saves time and money compared to purchasing individual components. Additionally, using high-quality seals ensures better performance and reliability, reducing the likelihood of future leaks.

Furthermore, performing regular maintenance with these kits helps to identify potential issues early on, preventing more significant problems down the line. This proactive approach is essential for minimizing downtime and maximizing productivity in industrial settings.

Conclusion

In conclusion, hydraulic cylinder repair seal kits are indispensable for the upkeep of hydraulic systems. By understanding the essential components included in these kits and their functions, operators can effectively maintain their hydraulic cylinders, ensuring optimal performance and longevity. Regular maintenance using quality repair kits not only enhances the reliability of the machinery but also contributes to overall operational efficiency, making them a worthwhile investment for any industrial application. Whether you are operating a small workshop or managing a large-scale industrial operation, having access to a reliable seal repair kit is paramount for maintaining the integrity of your hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories