វិច្ឆិកា . 24, 2024 15:54 Back to list

hub bearing seal

The Importance of Hub Bearing Seals in Automotive Engineering

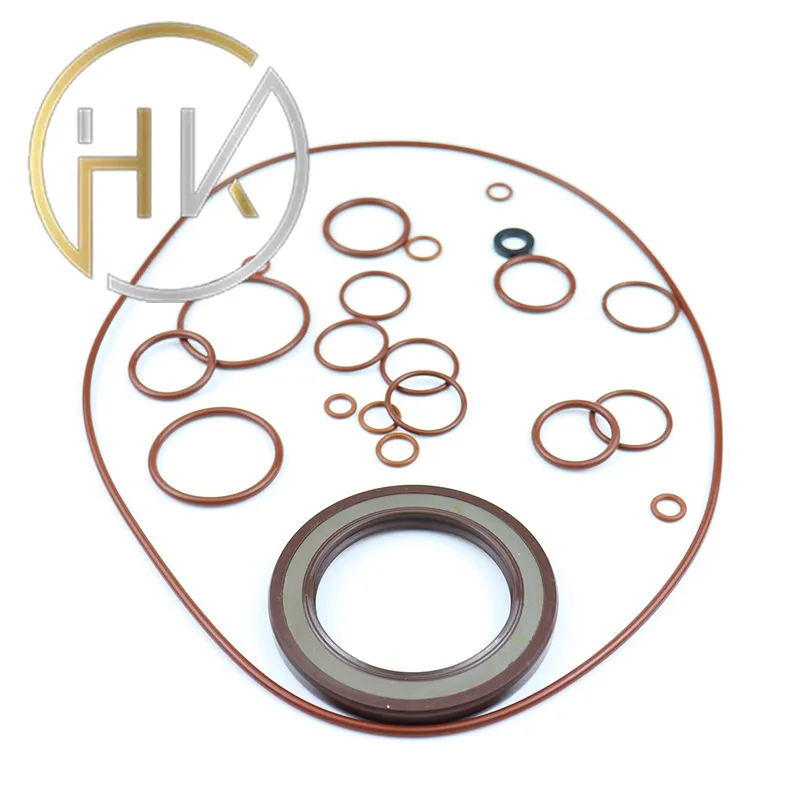

In the realm of automotive engineering, the hub bearing seal plays a critical role in ensuring the longevity and performance of vehicles. Often overlooked, these seals are crucial in maintaining the integrity and functionality of the wheel hub assembly. This article will explore the significance of hub bearing seals, their construction, and their impact on vehicle performance.

Hub bearing seals are specifically designed to prevent the ingress of contaminants such as dirt, moisture, and debris into the bearing assembly. The wheel hub houses various components, including the wheel bearings, which endure immense loads and stress during a vehicle’s operation. The primary function of the hub bearing seal is to create a barrier that keeps these essential components protected from external elements, thereby ensuring optimal performance and preventing premature wear.

Constructed from durable materials such as rubber or synthetic compounds, hub bearing seals are engineered to withstand varying temperature ranges, pressure fluctuations, and environmental conditions. The design typically incorporates a lip that makes contact with the bearing surface, effectively sealing the area. The quality of materials used in the seal’s construction directly influences its performance and durability. High-quality seals can significantly reduce friction, thereby enhancing the overall efficiency of the wheel hub assembly.

hub bearing seal

The implications of a faulty or ineffective hub bearing seal can be far-reaching. When seals degrade or fail, contaminants can infiltrate the bearing assembly, leading to increased friction, overheating, and eventual bearing failure. This not only compromises the safety of the vehicle but can also result in costly repairs. Regular inspection and maintenance of hub bearing seals are therefore essential for vehicle owners, as they play a vital role in a vehicle’s reliability and safety on the road.

Moreover, advancements in technology and materials have led to the development of high-performance hub bearing seals that offer enhanced protection and longevity. Manufacturers are increasingly investing in research and development to create innovative seal designs that can better withstand the rigors of modern automotive engineering. As vehicles become more sophisticated, with higher performance demands, the role of hub bearing seals becomes even more critical.

In conclusion, the hub bearing seal may seem like a minor component in the complex machinery of a vehicle, but its impact is significant. From protecting the wheel bearings to ensuring smooth operation and enhancing safety, hub bearing seals are indispensable in automotive engineering. As technology continues to evolve, so too will the design and functionality of these seals, further cementing their role in the future of vehicle performance. Vehicle owners should recognize the importance of these components and prioritize their maintenance to ensure a safe and reliable driving experience.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories