វិច្ឆិកា . 29, 2024 23:54 Back to list

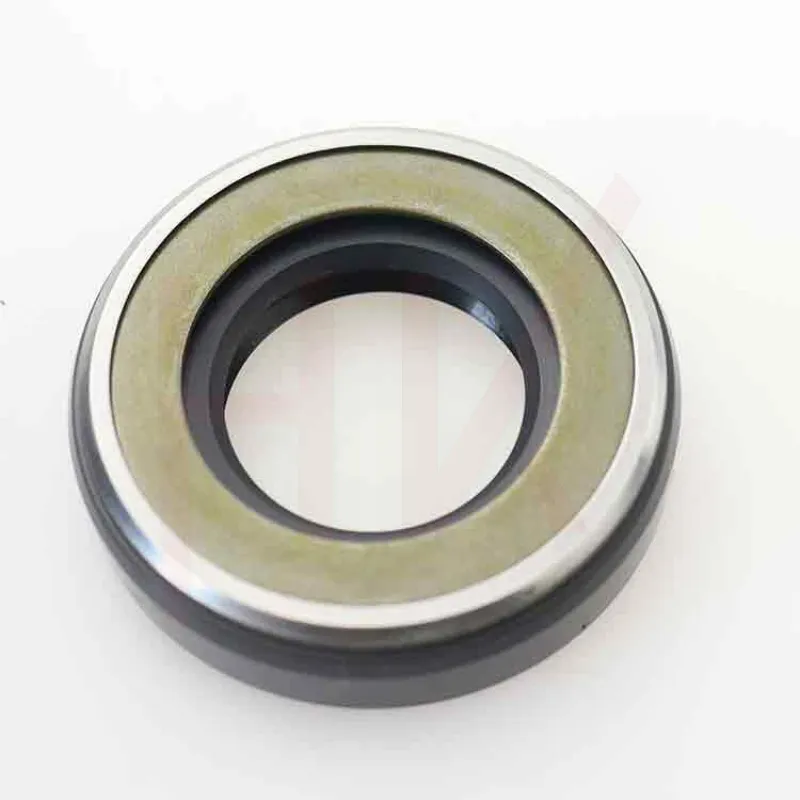

high temperature o ring kit

Understanding High Temperature O-Ring Kits Essential Components for Industrial Applications

In various industrial applications, ensuring the integrity of seals in high-temperature environments is crucial for the efficiency and safety of operations. Among the many sealing solutions available, high-temperature O-ring kits have emerged as vital components that meet the diverse needs of engineering, manufacturing, and maintenance. This article delves into the significance, composition, and applications of high-temperature O-ring kits, underscoring their role in sustaining operational performance.

What is an O-Ring?

An O-ring is a toroidal (doughnut-shaped) sealing element made from elastomeric materials. Its primary function is to create a seal at the interface of two or more components to prevent the leakage of fluids or gases. O-rings are favored for their simplicity, effectiveness, and versatility in various environments.

Importance of High-Temperature O-Rings

In industries such as petrochemical, aerospace, automotive, and food processing, components often operate under extreme temperature conditions. High-temperature O-rings are specially engineered to withstand elevated temperatures, which can range from 250°F (121°C) to over 500°F (260°C), depending on the material used. The significance of high-temperature O-rings lies in their ability to maintain sealing capability while resisting thermal degradation, which can lead to seal failure, leakage, and even catastrophic incidents.

Composition of High-Temperature O-Ring Kits

High-temperature O-rings are manufactured from specific materials that provide thermal resilience. Common materials for high-temperature O-rings include

1. Fluoroelastomers (FKM) These materials can handle temperatures up to 500°F (260°C) and are excellent for chemical resistance, making them suitable for harsh environments.

2. Silicone (VMQ) Silica-based compounds are ideal for temperatures ranging from -100°F (-73°C) to 500°F (260°C). They are often used in food and pharmaceutical applications due to their FDA compliance.

3. Polyacrylate (ACM) Withstanding high temperatures of up to 300°F (149°C), polyacrylate O-rings offer good resistance to lubricants and fuels.

4. TFE/P (Aflas®) These O-rings remain stable in high temperatures (up to 600°F or 316°C) and provide exceptional chemical resistance.

Each material possesses unique characteristics and is chosen based on the specific application and operational conditions

.Applications of High-Temperature O-Ring Kits

high temperature o ring kit

High-temperature O-ring kits serve a myriad of applications across different sectors, including

1. Oil and Gas Industry O-rings are crucial in valves, pumps, and compressors, where they prevent fluid leakage under high pressure and temperature.

2. Aerospace Engineering In aircraft engines and propulsion systems, O-rings ensure reliable seals to manage fuel and hydraulic fluids in extreme conditions.

3. Automotive Sector Engine components, transmission systems, and HVAC systems utilize high-temperature O-rings to maintain performance and safety.

4. Food and Beverage Processing Food-grade silicone O-rings are essential for seals in ovens, cookers, and steamers, ensuring hygiene and safety standards are met.

5. Chemical Manufacturing O-rings are used where aggressive chemicals and high temperatures are present, ensuring persistent sealing performance.

Advantages of Using High-Temperature O-Ring Kits

1. Reliability These O-rings provide dependable seals in demanding environments, enhancing operational efficiency and safety.

2. Cost-Effectiveness Utilizing high-temperature O-ring kits reduces the risk of leaks and failures, minimizing downtime and maintenance costs.

3. Customization Many manufacturers offer O-ring kits in various sizes and materials suited to specific applications, allowing for tailored solutions.

4. Ease of Installation O-rings are simple to install, requiring minimal tools, which can expedite both assembly and maintenance processes.

Conclusion

High-temperature O-ring kits are critical components that enhance the performance and safety of various industrial applications. By understanding their composition, benefits, and applications, businesses can make informed choices, ensuring optimal sealing solutions in high-temperature environments. As industries continue to innovate, the demand for reliable, effective sealing solutions like high-temperature O-rings will undoubtedly grow, underscoring their importance in the modern industrial landscape.

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

Products categories