វិច្ឆិកា . 06, 2024 07:19 Back to list

35x52x7 oil seal

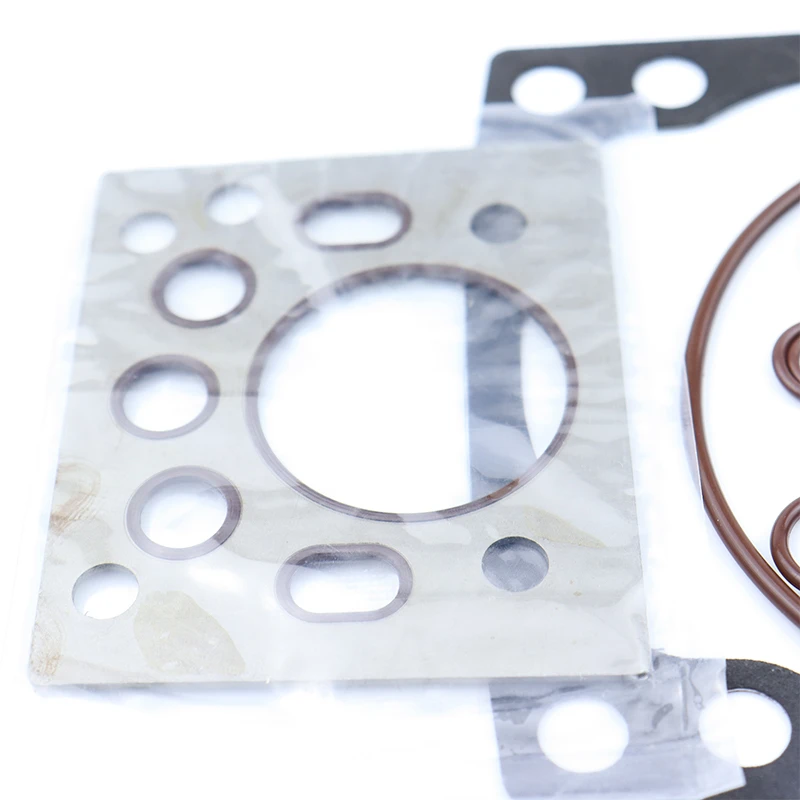

Understanding the 35x52x7 Oil Seal Specifications, Applications, and Benefits

Oil seals are critical components in various mechanical systems, designed to prevent leakage and contamination in equipment. The 35x52x7 oil seal is a specific type of radial lip seal that measures 35mm in inner diameter, 52mm in outer diameter, and has a cross-section of 7mm. Understanding its specifications, applications, and benefits can help in choosing the right seal for specific needs.

Specifications

The dimensions of the 35x52x7 oil seal indicate its compatibility with various industrial machinery. The inner diameter of 35mm allows it to fit snugly around a shaft of corresponding size, ensuring a secure seal. The outer diameter of 52mm creates a stable interface with the housing or casing where the seal is installed. The 7mm thickness is a standard measurement that provides sufficient durability while maintaining flexibility, which is essential for adapting to operational conditions.

Typically made from high-quality materials such as rubber or elastomers, these seals often include a metal casing for added strength and support. This construction allows them to withstand a range of temperatures, pressures, and potential chemical exposures, extending their lifespan and performance.

Applications

The 35x52x7 oil seal is widely utilized across various industries, including automotive, industrial machinery, and manufacturing

. In automotive applications, it is commonly found in engines, gearboxes, and differential assemblies, where it prevents oil leaks and protects against dirt and moisture. In industrial settings, the oil seal plays a vital role in pumps, compressors, and hydraulic systems, ensuring efficient operation and reducing maintenance costs.35x52x7 oil seal

Furthermore, the versatility of the 35x52x7 oil seal makes it suitable for applications involving both lubricating and hydraulic fluids, enhancing its utility across multiple sectors.

Benefits

Using the 35x52x7 oil seal brings several advantages. Firstly, it ensures a tight seal, which minimizes the risk of fluid leakage, thereby preserving the system's integrity and operational efficiency. Secondly, by preventing contaminants from entering the machinery, the oil seal helps to prolong the life of the equipment, reducing the need for frequent repairs or replacements. This can lead to significant cost savings over time.

Moreover, the ease of installation and replacement of oil seals contributes to efficient maintenance practices, allowing operators to swiftly service equipment without extensive downtime.

Conclusion

In summary, the 35x52x7 oil seal is an essential component across various industrial and automotive applications. With its specifications tailored to fit a range of machinery, it offers effective sealing solutions, enhances operational reliability, and provides economic benefits through reduced maintenance needs. Utilizing high-quality oil seals ensures the efficiency and longevity of equipment, making them a worthwhile investment for any operation.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories