តុលា . 15, 2024 00:08 Back to list

Specifications for 17x30x7 Oil Seal Dimensions and Uses in Machinery

The Importance of 17x30x7 Oil Seals in Machinery

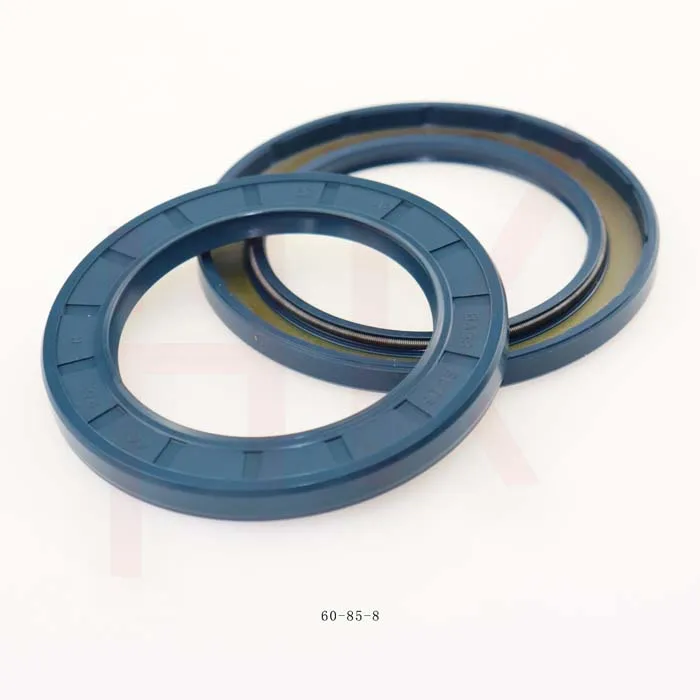

Oil seals are crucial components in numerous mechanical systems, designed to prevent the leakage of lubricants and contaminants while ensuring the efficient operation of machinery. One such significant oil seal is the 17x30x7 oil seal, named after its dimensions in millimeters—17mm inner diameter, 30mm outer diameter, and 7mm width. In this article, we will delve into the importance of the 17x30x7 oil seal, its applications, and the factors to consider when selecting one for your machinery.

Understanding Oil Seals

Before we explore the specific attributes of the 17x30x7 oil seal, it is essential to understand what oil seals are and their function. Often referred to as grease seals or rotary seals, oil seals are designed to seal around rotating shafts. Their primary purpose is to retain lubrication within the mechanical system while preventing external contaminants such as dirt and moisture from entering. The effective sealing of oil is vital for reducing wear and tear on the moving parts, thus prolonging the lifespan of machinery.

Applications of 17x30x7 Oil Seal

The 17x30x7 oil seal is commonly found in various applications across different industries

. These seals are typically utilized in automotive, industrial machinery, and agricultural equipment. In the automotive sector, they can be found in components such as transmissions, differentials, and wheel bearings, where they help maintain proper lubrication and prevent leakage.In industrial machinery, the 17x30x7 oil seal can be essential in applications ranging from pumps to motors and gearboxes. For agricultural equipment, such seals contribute to the reliable operation of machinery like tractors and harvesters, ensuring that essential lubricants are retained, which helps in preventing costly repairs and downtime.

Choosing the Right Oil Seal

17x30x7 oil seal

When selecting an oil seal, it’s essential to consider various factors to ensure compatibility and effectiveness. The material from which the seal is made is critical. Common materials include nitrile rubber (NBR), silicone, and fluor rubber (FKM). NBR is typically used for its excellent resistance to petroleum-based oils and temperature variations, making it a suitable choice for most applications. However, for environments with extreme temperatures or exposure to aggressive chemicals, selecting a seal made of silicone or FKM may be more appropriate.

Additionally, pay close attention to the operating conditions such as temperature, speed, and the type of lubricant used. Each application may have specific requirements that influence the choice of oil seal material and design.

Another aspect to consider is the design of the seal itself. The 17x30x7 oil seal can be found in various designs, including single lip or double lip configurations. A single lip seal may suffice for low-pressure applications, while double lip seals provide enhanced protection against contaminants, making them suitable for more demanding environments.

Maintenance and Replacement

Regular inspection and maintenance of oil seals are crucial for optimal performance. Signs of wear, such as leakage or visible damage, indicate that replacement may be necessary. Ignoring such signs can lead to significant machinery failure, ultimately resulting in increased downtime and repair costs.

When replacing a 17x30x7 oil seal, ensure that the new seal is installed correctly to avoid misalignment, which can lead to premature failure. Proper installation techniques include using the appropriate tools and following the manufacturer’s guidelines.

Conclusion

The 17x30x7 oil seal is a vital component in various mechanical systems, playing a crucial role in maintaining reliability and efficiency. Understanding its applications, the importance of material selection, and proper maintenance can significantly impact the performance of machinery. By paying close attention to these factors, engineers and technicians can ensure that their machinery operates seamlessly, minimizing downtime and maximizing productivity.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories