Қаң . 09, 2025 10:51 Back to list

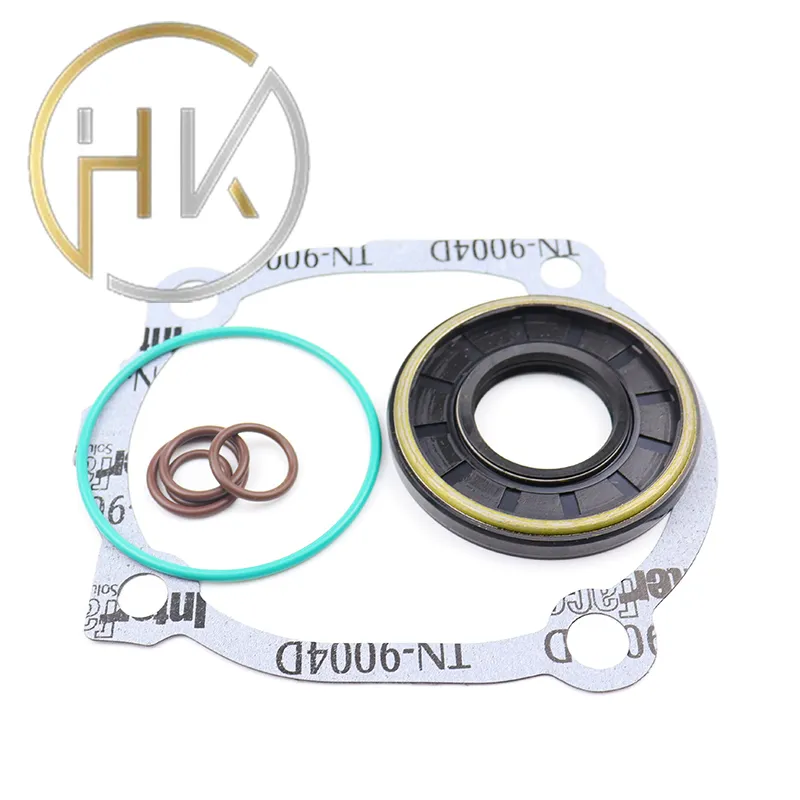

oil seal tcv

Trustworthiness is also paramount when selecting an oil seal supplier. A trusted manufacturer is characterized by their transparent operations, from sourcing raw materials to the delivery of finished products. They maintain open communication with clients, providing detailed product specifications, performance data, and testing results, which facilitates informed decision-making. Trust is further built through robust warranty policies, after-sales support, and a proven track record of reliability and customer satisfaction. Furthermore, a client-centric approach differentiates the best manufacturers. They collaborate closely with clients, offering customized sealing solutions that address unique operational challenges. A customer-focused manufacturer provides comprehensive services, from initial consultation and design through to implementation and ongoing maintenance support. This partnership approach ensures that the products not only meet but exceed client expectations, yielding beneficial outcomes like enhanced machine efficiency and reduced downtime. Finally, innovative manufacturers leverage digital tools to enhance customer experiences. Providing online resources such as detailed product catalogs, CAD designs, and technical papers facilitate easy access to critical information. These tools empower clients by simplifying the selection and integration of sealing solutions into their systems, thereby optimizing operations and reducing costs. In summary, selecting an oil seal manufacturer requires careful consideration of their experience, expertise, authority, and trustworthiness. A manufacturer excelling in these areas offers not just products, but comprehensive solutions that drive operational efficiency and success. Opt for a partner who aligns with these principles to ensure that your machinery performs reliably, safely, and cost-effectively over the long term.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories