Қар . 09, 2024 15:26 Back to list

Similar Solutions for Hub Dust Sealing and Protection Systems

Understanding Hub Dust Seals Importance, Types, and Maintenance

In the realm of mechanical engineering and automotive design, the hub dust seal plays a critical role in ensuring the longevity and efficiency of various machinery. These seals are specifically designed to protect rotating assemblies from the penetration of dust, dirt, and other contaminants, thereby ensuring optimal performance and reducing wear and tear on components.

What is a Hub Dust Seal?

A hub dust seal is a type of sealing device typically found in the wheel hubs of vehicles, rotating equipment, and machinery. Its primary function is to create a barrier against environmental contaminants while allowing for smooth rotation of components like wheel bearings. The effectiveness of a dust seal directly impacts the reliability and lifespan of the hub assembly, making it a vital component in any system that experiences rotational movement.

Importance of Hub Dust Seals

1. Contaminant Protection One of the most significant roles of a hub dust seal is to protect the internal components of a hub assembly from dust, dirt, moisture, and other foreign materials. Contaminants can cause corrosion, increased friction, overheating, and failure of bearing systems, which can lead to costly repairs and downtime.

2. Cost Efficiency By preventing wear and tear on critical components, hub dust seals contribute to lower maintenance costs. Regular replacement of seals can prevent larger and more expensive repairs, thereby extending the service life of the machinery or vehicle.

3. Enhanced Performance A properly installed and maintained hub dust seal facilitates smoother operation of rotating parts. This is particularly crucial in vehicles, where performance, safety, and handling depend on the integrity of wheel assemblies.

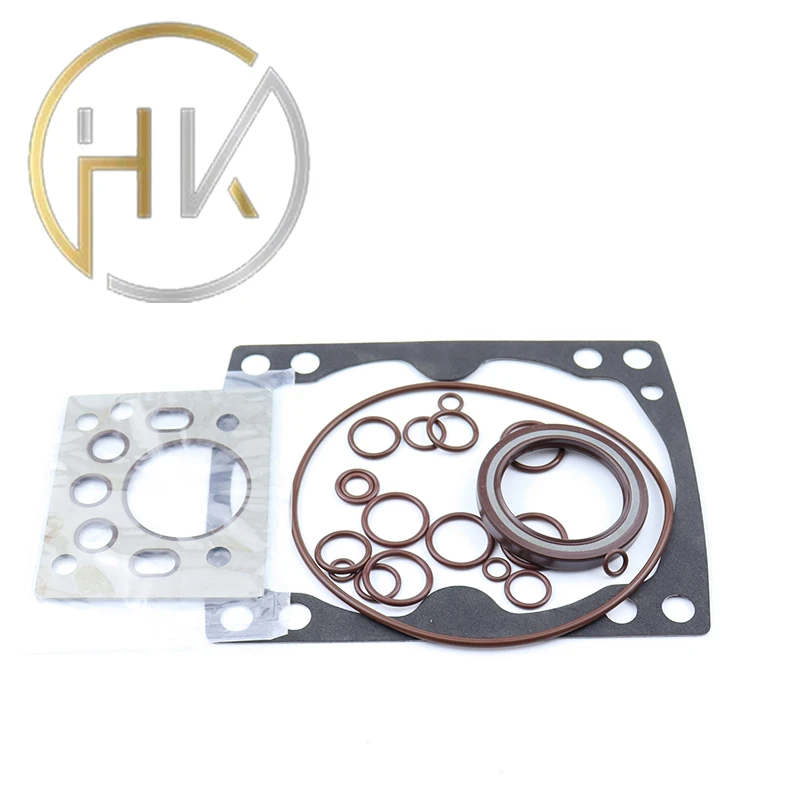

Types of Hub Dust Seals

Hub dust seals can be categorized based on their design and material composition

1. Lip Seals These are the most common type of dust seals, featuring a flexible lip that conforms to the surface of the hub. They can effectively keep out contaminants while minimizing friction.

hub dust seal

2. Radial Seals Radial seals provide a more robust sealing solution for applications requiring greater resistance to pressure and extreme conditions.

3. Mechanical Seals These seals use mechanical means to keep contaminants out. They can be more complex and are typically used in applications where higher levels of reliability are required.

4. V-Ring Seals This type of seal utilizes a unique v-shaped profile to create a tight fit against the rotating shaft. They are economical and effective for applications where high sealing performance is necessary without significant wear.

Maintenance of Hub Dust Seals

To ensure the longevity and effectiveness of hub dust seals, regular inspection and maintenance are crucial. Here are some best practices

1. Routine Checks Inspect seals periodically for signs of wear, damage, or contamination. Look for cracks, tears, or signs of fluid leakage.

2. Proper Installation Ensure that seals are installed correctly, following manufacturer specifications. Incorrect installation can lead to premature failure and contamination.

3. Environment Considerations Understand the working environment where the machinery operates. Extreme temperatures, high dust levels, or exposure to chemicals can affect seal performance.

4. Timely Replacement Replace worn or damaged seals promptly to prevent contaminants from entering the hub assembly.

Conclusion

Hub dust seals are indispensable components in mechanical applications, especially in the automotive industry. By preventing contamination and reducing friction, they ensure smooth operation, enhance performance, and prolong the service life of rotating assemblies. Understanding their importance, types, and maintenance practices is essential for anyone involved in the design, operation, or maintenance of machinery and vehicles. Investing in quality hub dust seals and adhering to maintenance guidelines can significantly impact overall operational efficiency and cost-effectiveness in the long run. As such, they play a crucial role in the successful operation of various mechanical systems.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories