იან . 14, 2025 10:57 Back to list

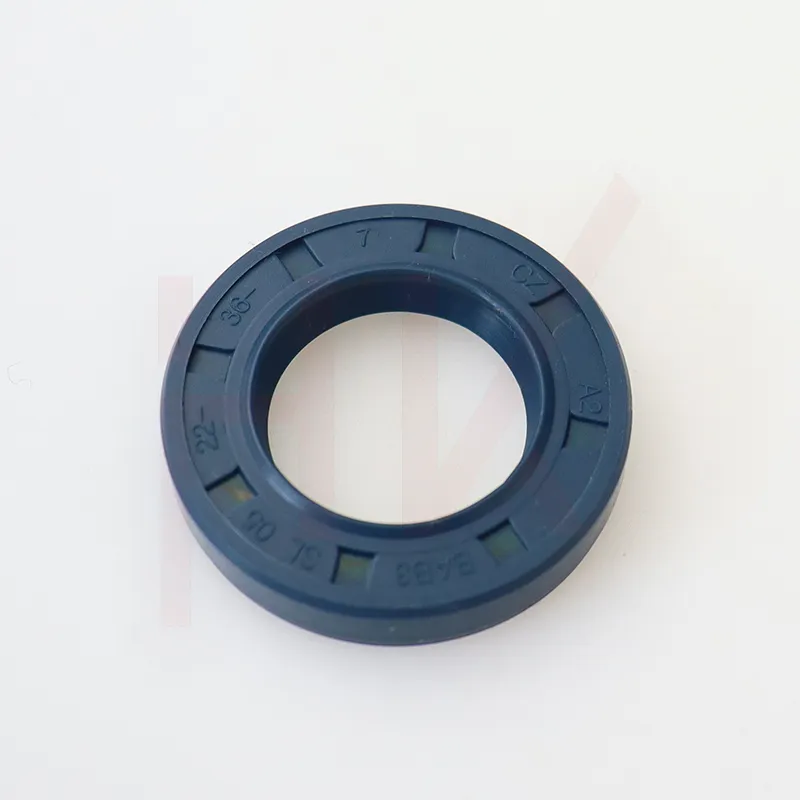

oil seal tcv

3. Wiper Seals Also known as scraper seals, these are essential in protecting the hydraulic system from dirt, debris, and moisture. They act as a barrier by cleaning the rod during reciprocation, thus preventing abrasives from entering the hydraulic system. Discussions among industry veterans reveal wiper seals help in extending the lifespan of both seals and hydraulic components by maintaining a cleaner operating environment. When implementing wiper seals, it’s critical to ensure they are perfectly aligned to avoid premature wear. 4. Buffer Seals Found in applications subject to high pressure, buffer seals serve to protect primary rod seals from pressure spikes by reducing load and pressure. They are an additional safeguard that enhances the reliability of high-performance systems. Technical evaluations show buffer seals are indispensable in preventing seal failure in rapidly changing pressure environments. Their effectiveness lies in material strength and flexibility; hence, choosing a high-grade buffer seal can result in better performance under extreme conditions. 5. Guide Rings Although not a seal, guide rings play an important supporting role in hydraulic systems. They provide lateral support to the piston and rod, preventing metal-to-metal contact. This function reduces wear and tear and maintains alignment, ensuring optimal performance of seals. Expert advice highlights the importance of selecting the right guide ring material such as PTFE, to meet specific load and temperature requirements. In conclusion, selecting the appropriate hydraulic oil seal type is contingent upon a comprehensive understanding of the system’s requirements and operating conditions. By placing a higher emphasis on the expertise in selecting materials and types of seals, industries can benefit from reduced downtimes, lower maintenance costs, and prolonged equipment lifespans. Hydraulics industry leaders agree that regular inspection and timely replacement of seals are crucial in maintaining optimal performance of hydraulic systems.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

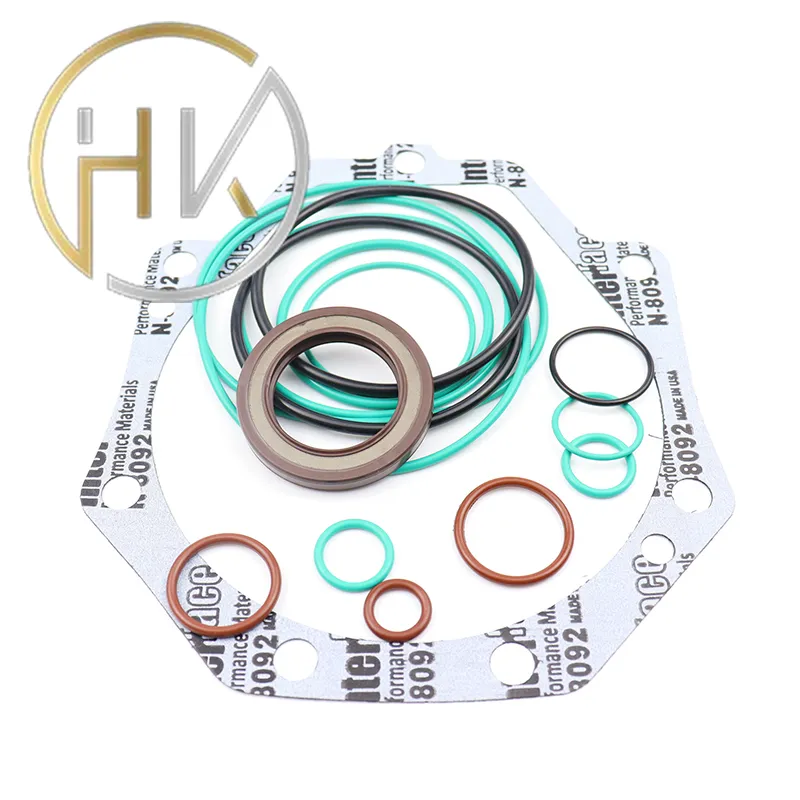

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories