ნოე . 05, 2024 13:59 Back to list

45x62x8 oil seal

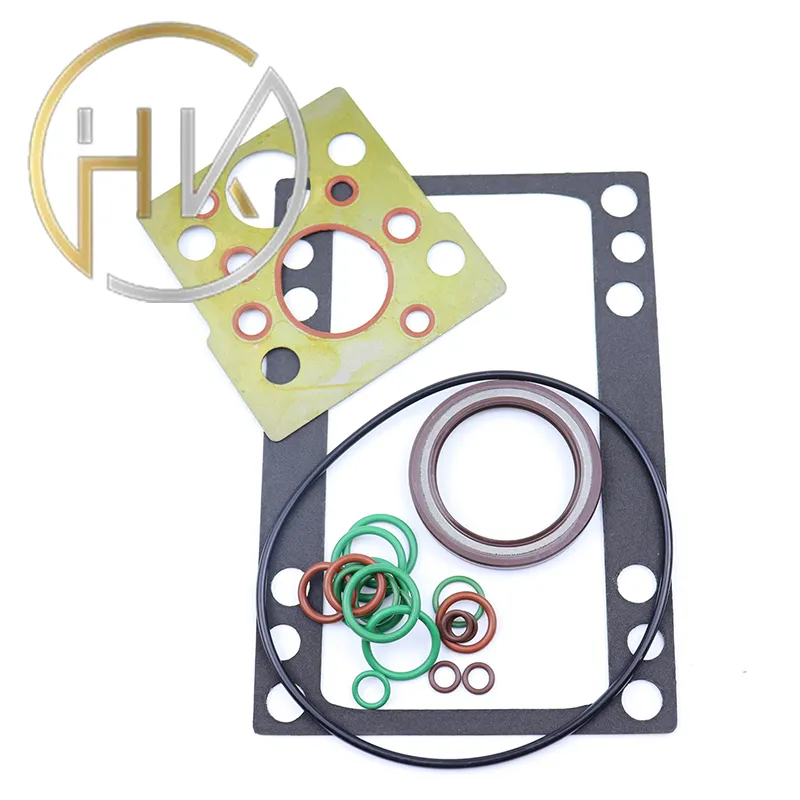

Understanding the 45x62x8 Oil Seal A Crucial Component in Machinery

When it comes to machinery and automotive applications, oil seals play a vital role in ensuring proper functionality and longevity. One specific type of oil seal, the 45x62x8 oil seal, is particularly noteworthy due to its dimensions and wide range of applications. This article delves into the importance of the 45x62x8 oil seal, its construction, and its various uses in different industries.

The designation 45x62x8 refers to the seal's dimensions a 45 mm inner diameter, a 62 mm outer diameter, and an 8 mm thickness. These measurements are crucial because they determine the seal’s compatibility with specific machinery parts. The primary function of the oil seal is to prevent leakage of lubricants and fluids while also keeping out dirt and contaminants. This is essential for maintaining the efficiency and performance of machinery, ultimately leading to reduced downtime and lower maintenance costs.

Typically made from high-quality rubber or synthetic materials, the 45x62x8 oil seal is designed to withstand various environmental conditions and temperatures

. The choice of material is essential, as it affects the seal's durability and performance. For instance, seals made from nitrile rubber offer excellent resistance to petroleum-based oils, while those crafted from fluorocarbon rubber can endure higher temperatures and aggressive chemicals.45x62x8 oil seal

The applications of the 45x62x8 oil seal are vast. In the automotive sector, it is commonly used in engines, transmissions, and differential components. Its ability to effectively seal against oil leaks not only preserves the integrity of the vehicle’s systems but also ensures optimal performance. Additionally, in industrial machinery, such as pumps, compressors, and electric motors, these seals are integral to preventing fluid leakage, which can lead to costly failures if not managed appropriately.

Moreover, the installation and maintenance of the 45x62x8 oil seal are straightforward. Typically, it requires a clean surface and precise alignment to ensure proper sealing. Regular inspections can help identify signs of wear or damage, allowing for timely replacements and preventing further issues down the line.

In conclusion, the 45x62x8 oil seal is a critical component in various machinery applications. Its ability to effectively prevent leaks and protect against contaminants makes it indispensable in maintaining the efficiency and longevity of both automotive and industrial equipment. Understanding its specifications and applications can help users make informed decisions, ensuring optimal performance and reliability in their operations.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories