Nov . 23, 2024 15:54 Back to list

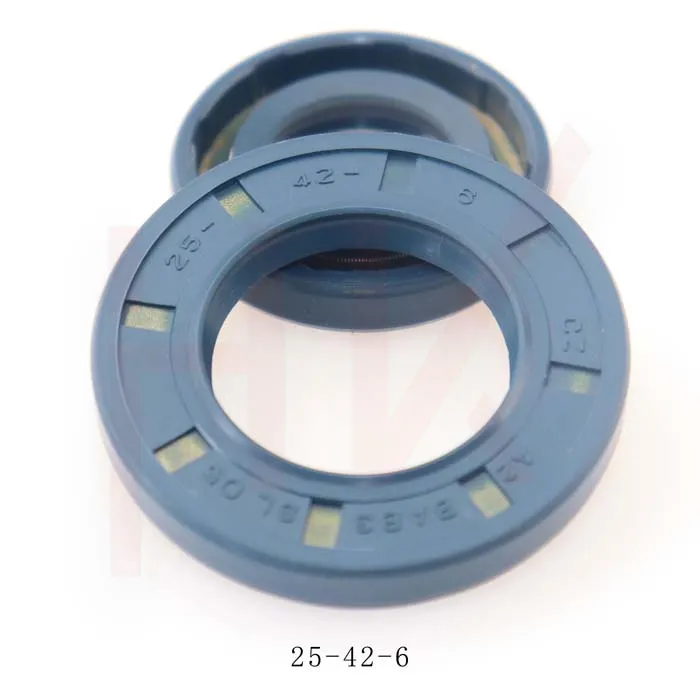

hydraulic cylinder seals

Understanding Hydraulic Cylinder Seals Essential Components for Performance and Longevity

Hydraulic cylinders are integral components in a wide range of machinery and applications, from construction equipment to automated manufacturing systems. One critical element that ensures the efficient operation of hydraulic cylinders is the seals. These seals play a fundamental role in preventing hydraulic fluid leakage, maintaining pressure, and ensuring the overall efficiency and longevity of the hydraulic system. In this article, we’ll explore the different types of hydraulic cylinder seals, their functions, and the factors to consider when choosing the right seal for your application.

The Importance of Hydraulic Cylinder Seals

Hydraulic cylinder seals serve several primary functions. First and foremost, they prevent hydraulic fluid from leaking out of the cylinder, which is crucial for maintaining the necessary pressure for operation. A seal failure can lead to a significant drop in hydraulic pressure, rendering the system inefficient or even inoperable. Additionally, seals prevent contaminants from entering the hydraulic system, which can cause damage to internal components such as pistons and cylinder walls. By keeping the hydraulic fluid clean and free from particulates, seals contribute to the system's longevity and reliability.

Types of Hydraulic Cylinder Seals

There are several types of seals used in hydraulic cylinders, each designed for specific applications and performance requirements. The most common types include

1. Rod Seals These seals are located on the piston rods and are responsible for preventing fluid from leaking out of the cylinder. They must withstand dynamic movement as the rod extends and retracts.

2. Piston Seals Found inside the cylinder, piston seals ensure that hydraulic fluid is effectively contained, allowing for the generation of force. Piston seals also must accommodate dynamic movements and pressure changes.

3. Wear Rings While not seals in the strictest sense, wear rings are crucial for guiding the piston within the cylinder and minimizing wear on the main sealing surfaces.

hydraulic cylinder seals

4. End Cap Seals These seals prevent fluid from leaking through the end caps of the hydraulic cylinder, providing an essential barrier against fluid loss.

Factors to Consider When Selecting Seals

When it comes to choosing the right hydraulic cylinder seals, several factors must be considered to ensure optimal performance and longevity

1. Material Compatibility Seals are made from various materials such as nitrile, polyurethane, and fluorocarbon. It is vital to select a material that is compatible with the hydraulic fluid being used, as well as the operating temperature and pressure ranges.

2. Operating Conditions The environment in which the hydraulic system operates can significantly impact seal performance. Factors such as temperature extremes, exposure to chemicals, and contamination levels should all influence the selection of seal materials and types.

3. Dynamic vs. Static Sealing Consider whether the application requires seals that can withstand constant movement (dynamic seals) or if they will primarily be in a stationary position (static seals).

4. Installation Design The design of the cylinder and the ease of seal installation and replacement are essential for maintenance. A design that accommodates easy access to seals can save time and reduce downtime.

Conclusion

Hydraulic cylinder seals are vital to the efficiency and longevity of hydraulic systems. By selecting the appropriate types of seals and understanding their functions, operators can enhance the performance of their equipment while minimizing the risk of leaks and contamination. Proper maintenance and timely replacement of seals will also contribute to the reliability and cost-effectiveness of hydraulic systems in various applications.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories