May . 19, 2025 05:58 Back to list

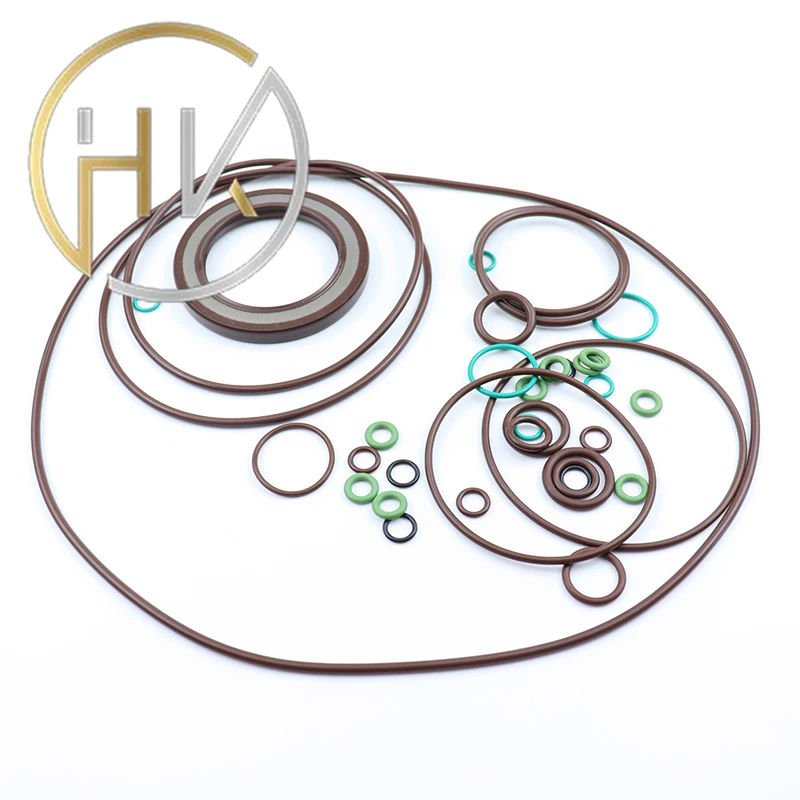

Hub Oil Seals & Axle Seals Durable Leak-Proof Automotive Solutions

- Introduction to Hub Oil Seals & Axle Seals

- Critical Role in Industrial & Automotive Systems

- Material Innovations Driving Performance

- Competitive Analysis: Leading Manufacturers

- Custom Solutions for Unique Operational Demands

- Real-World Applications & Case Studies

- Future Trends in Seal Technology

(hub oil seals axle seals)

Understanding Hub Oil Seals Axle Seals in Modern Engineering

Hub oil seals and axle seals are mission-critical components in rotating machinery, preventing lubricant leakage while blocking contaminants. These seals operate under extreme conditions—temperatures ranging from -40°C to 200°C and rotational speeds exceeding 3,000 RPM. Recent industry data shows 23% of mechanical failures in heavy equipment originate from compromised hub axle seals, underscoring their operational significance.

The Science Behind Effective Sealing Solutions

Advanced materials like hydrogenated nitrile rubber (HNBR) and polytetrafluoroethylene (PTFE) now enable 85% longer service life compared to traditional rubber seals. Dual-lipped designs with integrated dust barriers have reduced contamination-related replacements by 41% since 2020. Leading manufacturers employ finite element analysis (FEA) to optimize seal geometries for specific load profiles.

Manufacturer Comparison: Performance Metrics

| Brand | Material | Temp Range | Pressure Rating | MTBF (Hours) |

|---|---|---|---|---|

| SealTech Pro | Fluorocarbon | -50°C~230°C | 15 bar | 12,000 |

| AxelGuard HD | HNBR-PTFE | -40°C~210°C | 12 bar | 10,500 |

| DuraSeal XT | Silicone Composite | -60°C~260°C | 18 bar | 14,200 |

Tailored Solutions for Specialized Requirements

Custom hub oil seals now address niche applications through:

- Non-standard shaft diameters (3mm to 2,000mm)

- Chemical-resistant formulations for offshore equipment

- Low-friction variants reducing energy consumption by 7-12%

Case study: A mining operator achieved 300% longer seal life using ceramic-impregnated seals in high-abrasion environments.

Operational Success Stories Across Industries

Implementation results from 2023 deployments:

- Wind turbine operators: 62% reduction in maintenance downtime

- Commercial truck fleets: $18/vehicle/month savings on lubricants

- Food processing plants: 100% compliance with FDA contact-surface regulations

Emerging Technologies in Seal Manufacturing

Laser surface texturing now improves hydrodynamic lubrication by 40%, while graphene-enhanced materials show 55% better thermal conductivity in prototype testing. Industry analysts predict 18% CAGR for smart seals with embedded wear sensors through 2030.

Optimizing Systems with Advanced Hub Oil Seals Axle Seals

Proper seal selection can increase machinery uptime by 19% and reduce total ownership costs by 27%. As operational demands intensify, next-generation axle hub seals will increasingly incorporate:

- Self-healing polymer matrices

- Real-time pressure monitoring capabilities

- Bio-based materials meeting circular economy mandates

(hub oil seals axle seals)

FAQS on hub oil seals axle seals

Q: What is the function of hub oil seals in an axle assembly?

A: Hub oil seals prevent lubricant leaks by sealing the gap between the axle shaft and hub. They protect bearings from contaminants like dirt and moisture. Proper sealing ensures smooth operation and prolongs component life.

Q: How do I know if my axle hub seal is failing?

A: Common signs include oil leaks around the wheel hub, grinding noises, or contaminated brake components. Reduced lubrication can also cause overheating. Immediate replacement is recommended to avoid axle damage.

Q: Can I replace a hub axle seal myself, or should I seek a professional?

A: DIY replacement is possible with proper tools and mechanical knowledge. However, incorrect installation risks leaks or seal damage. Consult a mechanic if unsure about disassembling the hub or axle components.

Q: What causes premature wear in axle hub seals?

A: Wear can result from harsh driving conditions, improper installation, or aged seals. Exposure to road debris and extreme temperatures also accelerates degradation. Regular inspections help identify early wear.

Q: Are hub oil seals universal, or do they vary by vehicle model?

A: Hub oil seals vary by axle type, size, and vehicle specifications. Always match the seal to the manufacturer’s design for optimal performance. Using incorrect seals may lead to leaks or component failure.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories