11月 . 27, 2024 10:35 Back to list

Oil Seal Specifications for 32 47 7 Applications and Performance Analysis

The Importance of Selecting the Right Oil Seal A Focus on the 32% 2047 7 Oil Seal

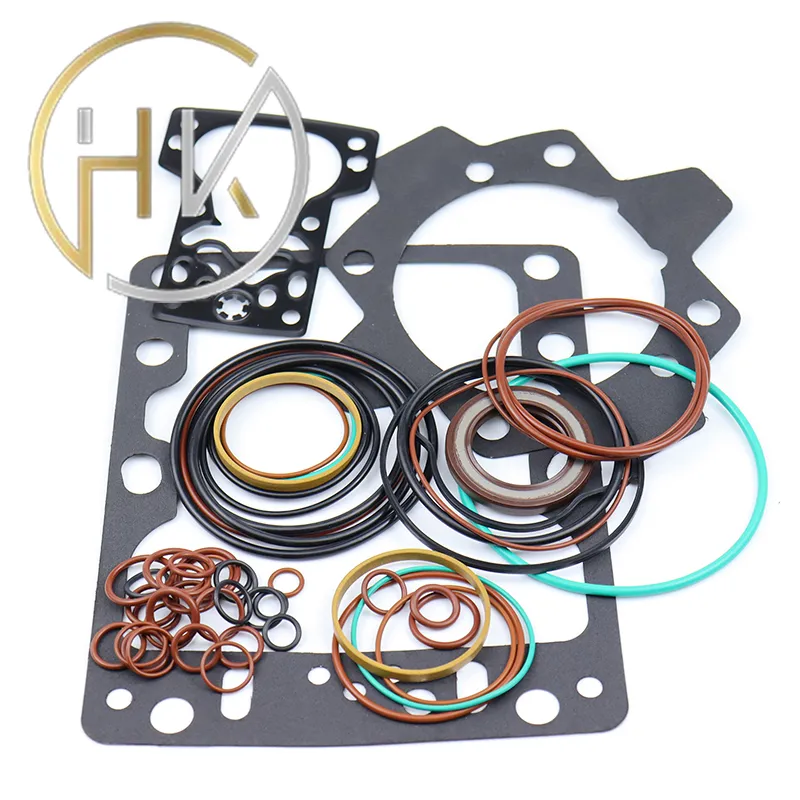

In the realm of mechanical engineering and equipment maintenance, the oil seal stands as a crucial component, often overlooked yet vital for ensuring the longevity and functionality of various machinery. Among the myriad of oil seals available, the 32% 2047 7 oil seal emerges as a notable option that warrants attention due to its unique specifications and applications. This article will delve into the significance of oil seals, the characteristics of the 32% 2047 7 oil seal, and the factors to consider when selecting the appropriate oil seal for your needs.

Understanding Oil Seals

An oil seal is a mechanical component that serves to seal lubricants, oil, or hydraulic fluids into a system while preventing contamination from external substances. These seals are crucial in applications involving rotating shafts, where they help to maintain pressure, reduce friction, and prevent leaks. The correct functioning of an oil seal is integral to the performance and efficiency of machinery, and its failure can lead to severe operational issues, increased wear and tear, and ultimately, costly repairs.

The 32% 2047 7 Oil Seal

The designation 32% 2047 7 provides insights into the specific attributes of this oil seal. The initial figure, 32%, typically indicates the material composition, which often includes a blend of synthetic rubbers, providing enhanced resistance to wear and temperature variations. The subsequent numbers, 2047 and 7, reflect the dimensions, specifically the inner and outer diameters, and the thickness of the seal, which are critical in ensuring a proper fit within the application.

One of the standout features of the 32% 2047 7 oil seal is its ability to withstand extreme conditions. It is designed to operate effectively within a wide temperature range and various pressure levels, making it suitable for diverse industrial applications. Whether used in automotive engines, hydraulic systems, or manufacturing machinery, this oil seal offers reliable performance, minimizing the risk of leakage and maintaining optimal lubrication.

Key Considerations When Choosing an Oil Seal

32 47 7 oil seal

When selecting an oil seal, several factors must be taken into account to ensure optimal performance and longevity

1. Material Compatibility It is essential to choose an oil seal made from materials compatible with the fluids it will contain. For instance, if the oil is synthetic or contains specific additives, the seal material should be resistant to those chemicals to prevent degradation.

2. Temperature and Pressure Ratings Understanding the operational conditions of the machinery is vital. The oil seal must be able to withstand the temperature fluctuations and pressure changes that occur during operation to ensure long-lasting functionality.

3. Dimensions and Fit The size and fit of the oil seal are critical. Using an incorrectly sized seal can lead to leaks and increased wear. Always refer to the manufacturer’s specifications for the correct dimensions.

4. Application Type Different applications may require specific types of seals. For instance, seals in automotive applications may need to be more robust than those used in light machinery operations.

5. Installation and Maintenance Proper installation procedures must be followed to ensure that the oil seal functions effectively. Regular maintenance checks can help identify potential issues before they escalate.

Conclusion

In conclusion, the 32% 2047 7 oil seal exemplifies the importance of selecting the right oil seal for various applications. By understanding the role that oil seals play in machinery performance and considering the key factors for selection, users can ensure they are making informed choices that ultimately lead to better efficiency, reduced maintenance costs, and prolonged equipment life. In industries where machinery reliability is paramount, investing in high-quality components like the 32% 2047 7 oil seal is not just a best practice; it's a necessary strategy for success.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories