Dic . 03, 2024 21:00 Back to list

Exploring Shaft Seal Applications in Wheel Hub Designs and Performance Enhancements

Understanding Shaft Seal Wheel Hubs Essential Components for Vehicle Longevity

In the intricate machinery of modern vehicles, every component plays a crucial role in ensuring optimal performance and longevity. One such critical component is the shaft seal, particularly in the context of wheel hubs. Understanding its function, types, and maintenance can significantly impact vehicle efficiency and durability.

What is a Shaft Seal?

A shaft seal, also known as a rotary seal or oil seal, is a device designed to seal the area between a rotating shaft and the stationary part of an assembly. Its primary job is to prevent the loss of lubricants and protect the internal components from external contaminants such as dirt, water, and debris. In wheel hubs, this function is essential, as it ensures that lubricants remain within the bearings and other critical areas, facilitating smooth operation and reducing wear.

The Role of Wheel Hubs

Wheel hubs are the points at which wheels are attached to the vehicle. They house the wheel bearings and connect to the suspension system, playing a pivotal role in the vehicle’s handling, stability, and overall performance. Given their importance, any failure in the wheel hub or its components can lead to severe mechanical issues, affecting ride comfort and safety.

Importance of Shaft Seals in Wheel Hubs

The shaft seals in wheel hubs serve several key functions 1. Lubricant Retention By providing a barrier against environmental contaminants, shaft seals ensure that lubricants remain within the bearings, reducing friction and thermal stress. 2. Contaminant Protection These seals help prevent contaminants from entering the hub assembly, which can lead to premature wear of bearings and other critical components. 3. Performance Assurance Properly functioning shaft seals contribute to overall vehicle performance by maintaining optimal operating conditions within the wheel hub.

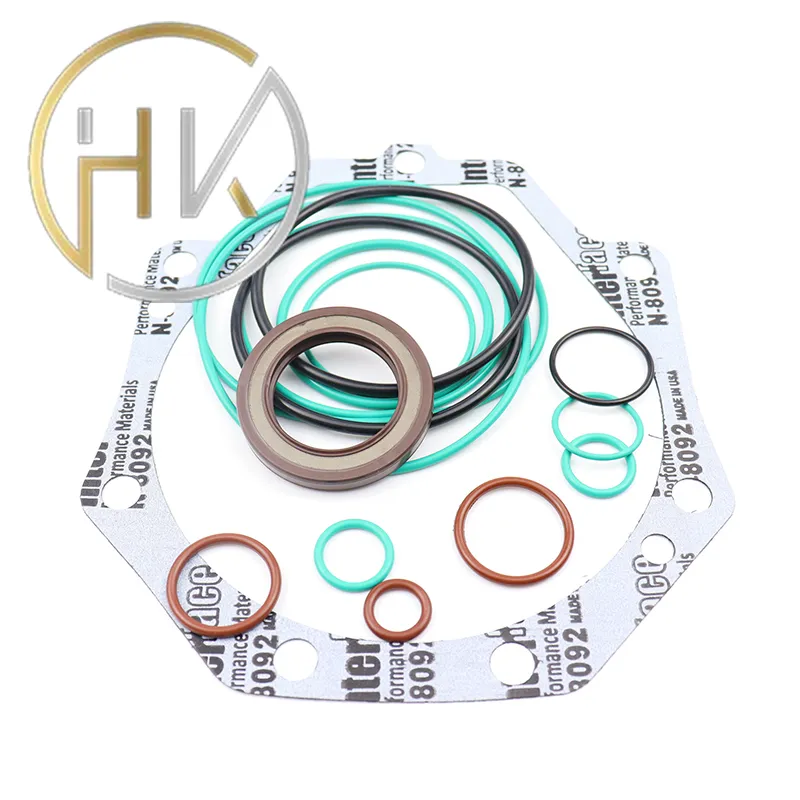

shaft seal wheel hub

Types of Shaft Seals

Several types of shaft seals can be used in wheel hubs, including - Lip Seals These are the most common type of shaft seals, featuring a flexible lip that contacts the shaft to create a seal. They are excellent at retaining lubricants and keeping contaminants out. - V-Ring Seals These seals are designed to fit over a rotating shaft and offer a reliable barrier against debris and moisture while allowing some flexibility for movement. - Oil Seals Specifically designed to manage lubricants, oil seals are often used in applications where there is a need for high-pressure containment, making them suitable for heavy-duty wheel hub applications.

Maintenance and Replacement

While shaft seals are designed for durability, they can wear out over time due to environmental factors, age, or improper installation. Regular inspection of the wheel hub and its components is crucial. Signs that a shaft seal may need replacement include - Visible leakage of lubricant around the wheel hub. - Unusual noise from wheel bearings, indicating insufficient lubrication. - Increased resistance while rotating the wheel, suggesting contamination.

Replacing a shaft seal is generally a straightforward process; however, it is recommended that this be performed by a qualified technician to ensure proper installation and prevent future issues.

Conclusion

Shaft seals within wheel hubs are integral to vehicle functionality. By preventing lubricant loss and protecting against contaminants, they help maintain the longevity and performance of critical wheel hub components. Understanding the function and importance of these seals can empower vehicle owners to take proactive steps in maintaining their cars. Regular inspections and timely replacements can safeguard against costly repairs and extend the overall life of the vehicle. Investing in quality shaft seals and ensuring proper maintenance not only enhances vehicle performance but also contributes to safer driving experiences on the road.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories