Dic . 17, 2024 08:01 Back to list

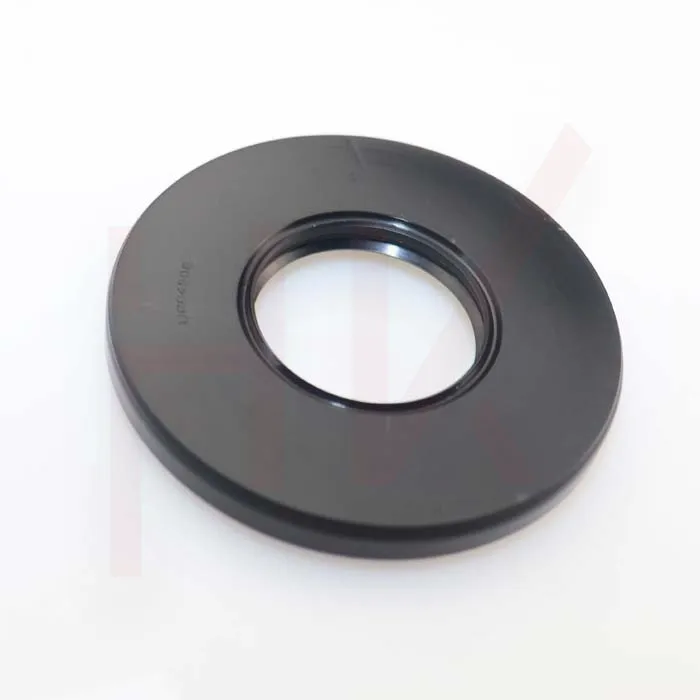

hydraulic press machine oil seal

Understanding the Hydraulic Press Machine Oil Seal An Essential Component

In the world of manufacturing and heavy machinery, the hydraulic press machine plays a pivotal role in various applications, from metal forming to plastic molding. One of the critical components that ensure the smooth operation of these machines is the hydraulic press machine oil seal. This article delves into the importance of the oil seal, its function, types, and maintenance to ensure the efficiency and longevity of hydraulic press machines.

What is an Oil Seal?

An oil seal is a device used to retain lubricants within a machine, preventing leakage and contamination. It is essential for maintaining the hydraulic fluid integrity in hydraulic systems, where any leakage can lead to decreased efficiency and increased operational costs. The oil seal consists of several parts, including a sealing lip, a body, and sometimes a spring, which together create a tight barrier against fluid loss.

Function of Oil Seals in Hydraulic Press Machines

In hydraulic press machines, oil seals serve several critical functions

1. Leak Prevention The primary role of an oil seal is to prevent hydraulic fluid from leaking out of the system. This is crucial because hydraulic fluids are pressurized, and even a small leak can lead to significant loss of efficiency.

2. Contamination Protection Besides keeping the hydraulic oil inside, oil seals also prevent dust, dirt, and other contaminants from entering the hydraulic system. Contaminants can cause severe damage to the hydraulic components, leading to costly repairs and downtime.

3. Maintaining Pressure Oil seals help maintain the necessary pressure within the hydraulic system, enabling it to operate effectively. In hydraulic presses, maintaining pressure is crucial for achieving the desired force and work output.

Types of Hydraulic Press Machine Oil Seals

There are various types of oil seals available, each designed for specific applications and operational conditions. The most common types include

- Rotary Oil Seals These seals are used where there is rotational motion, effectively sealing the shaft and preventing fluid leaks.

hydraulic press machine oil seal

- Static Oil Seals Ideal for applications where there is no rotational movement, these seals are used to seal stationary components

.- U-Cups Common in hydraulic applications, U-cups provide a reliable seal by adapting to different pressures within the system.

- Lip Seals Featuring a specially designed lip, these seals provide a robust barrier against both fluids and contaminants.

Maintenance of Oil Seals

To ensure the optimal performance of an oil seal in a hydraulic press machine, regular maintenance is essential. Here are some key maintenance tips

1. Regular Inspections Conduct routine checks for signs of wear, cracks, or deformation in the seals. Early detection can prevent more significant issues down the line.

2. Proper Lubrication Ensure that the oil seal is adequately lubricated to reduce friction, which can lead to premature wear.

3. Temperature Monitoring Overheating can damage oil seals. Monitoring the temperature of the hydraulic system helps prevent overheating, prolonging the life of the seals.

4. Correct Installation Ensure that oil seals are installed correctly to avoid leaks. Improper installation can lead to premature failure and system inefficiency.

Conclusion

The hydraulic press machine oil seal is a vital component that plays a significant role in maintaining the efficiency and functionality of hydraulic systems. By understanding the importance of oil seals, their types, and the best maintenance practices, operators can ensure the smooth operation of their hydraulic press machines, reduce downtime, and optimize production processes. Investing time in maintaining these seals is crucial for enhancing the longevity and reliability of hydraulic equipment in any manufacturing setting.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories