Gen . 21, 2025 02:50 Back to list

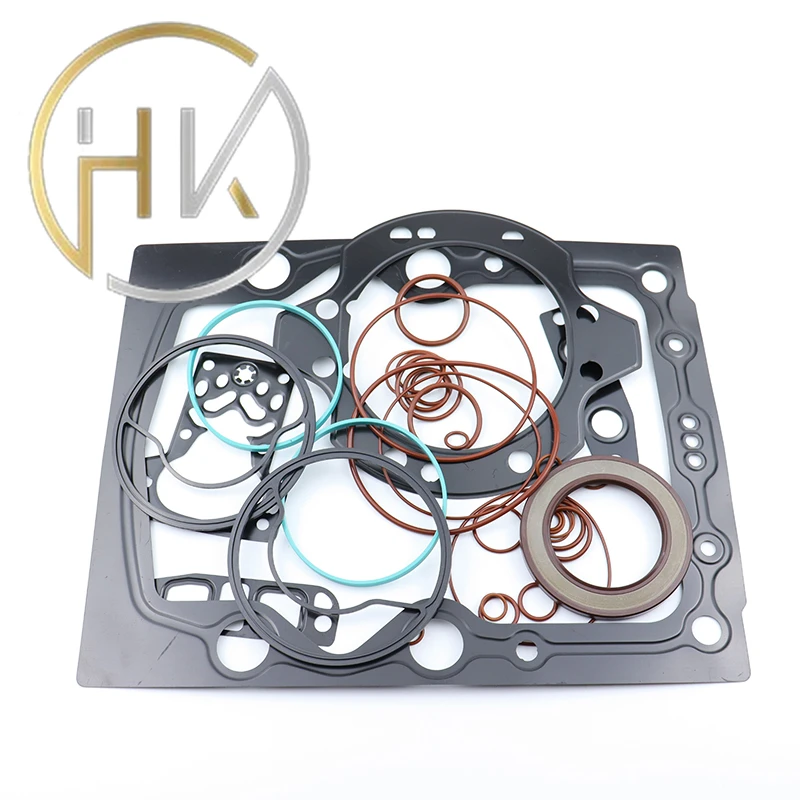

wiper seals

Cylinder wiper seals are pivotal components in hydraulic and pneumatic systems, frequently overlooked yet indispensable. Their primary function is to remove dust, dirt, and moisture from the piston rod, preventing contamination of the hydraulic or pneumatic fluid, thus ensuring the efficiency and longevity of the machinery. The effectiveness of a wiper seal directly relates to the system’s performance, making it an essential element for any industry relying on hydraulic systems.

Adopting advanced manufacturing processes has facilitated the production of more effective and reliable wiper seals. Technologies like computer-aided design and precision molding have allowed manufacturers to produce seals with higher degrees of accuracy and durability. These innovations ensure that the seals can withstand rigorous conditions, providing unprecedented levels of performance and reliability. The significance of cylinder wiper seals extends beyond their primary function. They contribute indirectly to environmental sustainability by minimizing fluid leakage, thus reducing the need for frequent fluid replacement and decreasing waste. Moreover, by protecting the internal components of hydraulic systems from contaminants, wiper seals prolong the life of these components, contributing to fewer replacements and less equipment disposal. Professional expertise and trustworthiness are paramount in the selection, installation, and maintenance of cylinder wiper seals. Engaging with reputable suppliers who possess extensive knowledge and experience can make a considerable difference. Their expertise can provide invaluable insight into the latest developments and best practices, ensuring that systems remain efficient and reliable. In industries where machinery uptime equates to profitability, the small cylinder wiper seal proves to be of profound importance. By meticulously selecting the right seal and maintaining it correctly, industries ensure that their hydraulic systems provide reliable and efficient service. The adoption of innovative materials and technologies in seal design further assures that these components meet the ever-evolving demands of contemporary industrial applications. Selecting and using the right cylinder wiper seal is not a product purchase—it's a long-term strategy for operational excellence.

Adopting advanced manufacturing processes has facilitated the production of more effective and reliable wiper seals. Technologies like computer-aided design and precision molding have allowed manufacturers to produce seals with higher degrees of accuracy and durability. These innovations ensure that the seals can withstand rigorous conditions, providing unprecedented levels of performance and reliability. The significance of cylinder wiper seals extends beyond their primary function. They contribute indirectly to environmental sustainability by minimizing fluid leakage, thus reducing the need for frequent fluid replacement and decreasing waste. Moreover, by protecting the internal components of hydraulic systems from contaminants, wiper seals prolong the life of these components, contributing to fewer replacements and less equipment disposal. Professional expertise and trustworthiness are paramount in the selection, installation, and maintenance of cylinder wiper seals. Engaging with reputable suppliers who possess extensive knowledge and experience can make a considerable difference. Their expertise can provide invaluable insight into the latest developments and best practices, ensuring that systems remain efficient and reliable. In industries where machinery uptime equates to profitability, the small cylinder wiper seal proves to be of profound importance. By meticulously selecting the right seal and maintaining it correctly, industries ensure that their hydraulic systems provide reliable and efficient service. The adoption of innovative materials and technologies in seal design further assures that these components meet the ever-evolving demands of contemporary industrial applications. Selecting and using the right cylinder wiper seal is not a product purchase—it's a long-term strategy for operational excellence.

Previous:

Next:

Latest news

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

Products categories