Dic . 12, 2024 06:13 Back to list

custom made oil seals

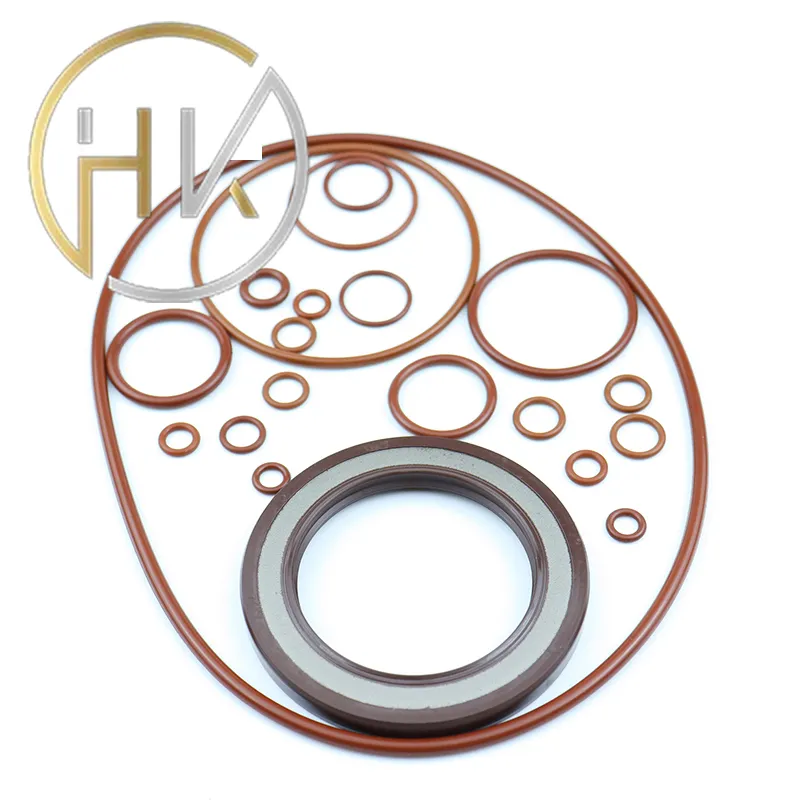

The Importance of Custom-Made Oil Seals in Industry

In various industrial applications, the significance of oil seals cannot be overstated. These small yet crucial components serve the primary purpose of containing lubricants while preventing the ingress of dirt and moisture. However, not all operations can utilize standard oil seals due to the unique requirements of their machinery. This is where custom-made oil seals come into play, providing tailored solutions to specific challenges faced in different operational environments.

Understanding Oil Seals

Oil seals, also known as rotary shaft seals, are mechanical components designed to seal the interface between stationary and moving parts. They consist of several elements, including a sealing lip, a case, and a spring. The sealing lip creates a barrier against leakage, effectively retaining oil in machinery such as engines, gearboxes, and hydraulic systems.

Standard oil seals vary in size, material, and design, allowing for widespread use across various sectors. However, many industries, such as automotive, aerospace, and manufacturing, often encounter unique circumstances that necessitate tailored solutions. This is where custom-made oil seals become not just beneficial but essential.

The Need for Custom Solutions

Every industrial application has distinct characteristics that can impact the performance of oil seals. Factors such as temperature fluctuations, chemical exposure, and the specific geometry of the machinery often require custom-designed seals. By opting for custom-made oil seals, businesses can ensure that their equipment operates efficiently, reducing the risk of leaks, downtime, and costly repairs.

For instance, a factory operating in a high-temperature environment may require oil seals made from heat-resistant materials. Conversely, an application that involves exposure to corrosive chemicals would benefit from seals engineered with specialized compounds that resist degradation. These tailored solutions help maintain the integrity of the machinery and, ultimately, the productivity of the operation.

custom made oil seals

Advantages of Custom-Made Oil Seals

1. Enhanced Performance Custom-made oil seals are designed specifically for an application, ensuring optimal performance and longevity. They fit more precisely, reducing the likelihood of leaks and prolonging the life of the equipment.

2. Cost-Efficiency Investing in bespoke seals can lead to significant cost savings in the long run. By reducing the incidence of equipment failure and the need for frequent replacements, custom seals help businesses save money on downtime and maintenance.

3. Improved Reliability Custom seals increase the reliability of machinery, contributing to smoother operations. When machinery operates without interruptions due to seal failures, productivity can significantly improve.

4. Flexibility in Design Custom manufacturers can tailor every aspect of an oil seal, from its size to the materials used. This flexibility allows businesses to develop innovative solutions that meet their specific needs, setting them apart from competitors that rely solely on standard products.

5. Technical Support Many manufacturers of custom oil seals provide technical expertise in selecting materials and designs that best suit a client’s application. This additional support can be invaluable in ensuring that the best solution is found.

Conclusion

Custom-made oil seals represent a vital investment for industries that require specific solutions to seal their equipment effectively. Through tailored designs, businesses can achieve enhanced performance, improved reliability, and significant cost savings. As industries continue to evolve, the demand for specialized components like custom oil seals will only grow, making them an essential aspect of modern industrial operations. By prioritizing quality and precision in this regard, companies can position themselves for success in an increasingly competitive landscape.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories