feb . 17, 2025 20:52 Back to list

wiper seals

Authoritative guidance from industry standards and manufacturers often underlines key practices in seal selection and installation. For example, ensuring the seal is compatible with both the operational temperature range and the specific hydraulic fluid is critical. Moreover, using precise tools and methodologies for installation prevents damage and ensures a perfect fit, which is crucial for maintaining the system's effectiveness. Trustworthiness in suppliers and products also cannot be overstressed. A reputable seal provider will offer comprehensive support, from expert consultations to technical datasheets that furnish detailed insights into each seal's performance characteristics. Such transparency aids engineers in making informed decisions that align with both technical requirements and budgetary constraints. To sum up, rod wiper seals are not merely accessories but essential components that demand thoughtful consideration in their selection and application. Leveraging expertise and authoritative resources ensures these seals serve their purpose effectively, safeguarding systems against potential contaminants. This comprehensive approach not only underscores the importance of rod wiper seals in maintaining hydraulic system efficiency but also aligns with the best practices for fostering longevity and reliability in operational environments.

-

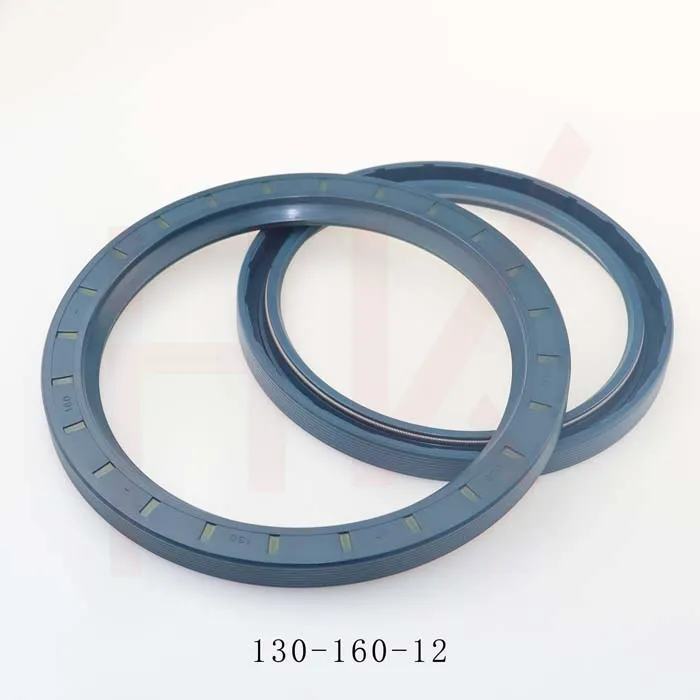

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories