jan . 22, 2025 02:02 Back to list

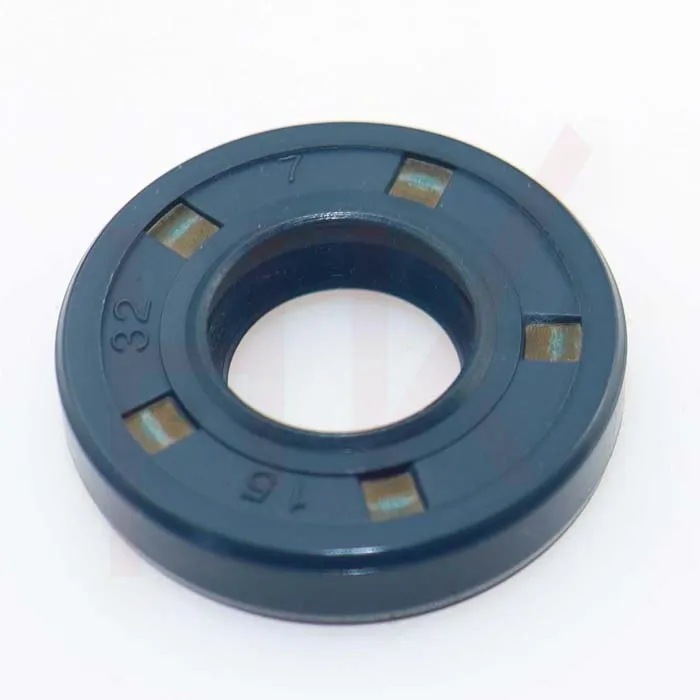

piston wiper ring

Authoritative sources like automotive engineering manuals and OEM guidelines provide detailed specifications and installation techniques for piston wiper rings, underscoring their importance. They recommend adhering to torque settings and following a cross-pattern sequence during installation to ensure uniform pressure on all rings, preventing distortion. Importantly, these documents highlight the necessity of maintaining operational clearances and correct end-gap settings, as deviations can lead to increased wear or catastrophic failure. Trustworthy automotive suppliers and manufacturers also emphasize the significance of genuine parts over generic alternatives, asserting that OEM piston wiper rings are designed to exactly fit the engine’s specifications. Using authentic parts not only guarantees compatibility and performance but also comes with the assurance of superior material quality and engineering precision. In conclusion, piston wiper rings, while seemingly minor components, play a vital role in the smooth operation of an engine. Through a combination of material expertise, proper installation practices, and regular maintenance, they ensure an optimal seal that mitigates oil wastage and boosts engine performance. For enthusiasts and professionals alike, understanding these elements contributes to enhanced decision-making regarding engine care and maintenance, ultimately leading to longer-lasting and more efficient engines.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories