jan . 09, 2025 12:27 Back to list

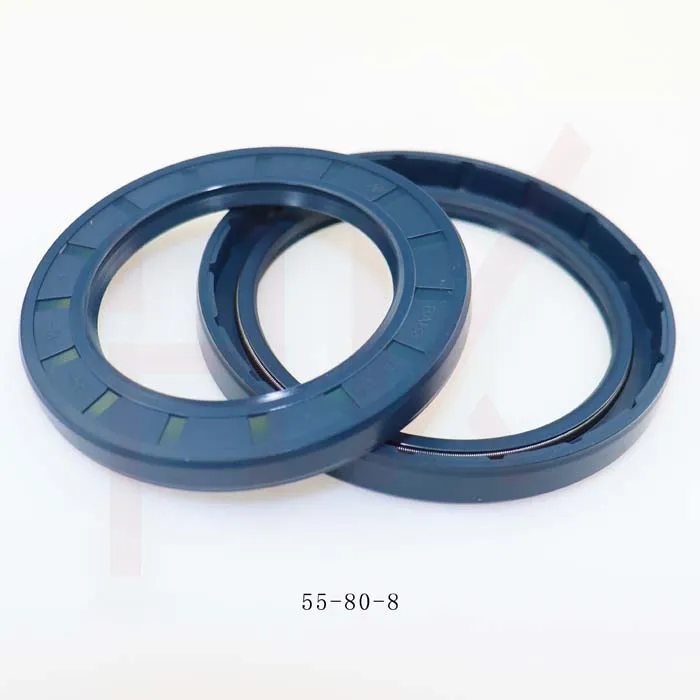

oil seal manufacturer

Authoritativeness in oil seal manufacturing denotes a company's influence and reputation within the industry. Manufacturers who have established themselves as industry leaders often participate in or contribute to the development of industry standards and best practices. They might be involved with various industry associations and are typically recognized for their contributions to technological advancements in seal manufacturing. Authoritative manufacturers are also often the go-to source for industry insights and innovations, underscoring their credibility and influence in shaping industry trends. Trustworthiness and credibility are foundational to any business relationship. A trustworthy oil seal manufacturer consistently fulfills their promises on quality, time-bound delivery, and post-sale support. They adhere to rigorous quality control standards, verified by relevant certifications such as ISO certifications or other industry-specific regulatory compliances. Testimonials and case studies from reputable clients can also offer insights into the reliability and integrity of a manufacturer, providing additional layers of assurance to potential customers. In conclusion, the choice of an oil seal manufacturer demands a careful evaluation of their experience, expertise, authoritativeness, and trustworthiness. A manufacturer who excels in these areas is more likely to supply products that enhance operational efficiency, ensure longer service life, and provide strong technical support. Taking the time to investigate these qualities not only helps in fostering a robust partnership but also in securing high-performance seals that meet your business's unique operational demands.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories