des . 04, 2024 09:53 Back to list

hydraulic ram rebuild kit

Understanding Hydraulic Ram Rebuild Kits A Comprehensive Guide

Hydraulic rams are vital components in various industries, facilitating the lifting and movement of heavy loads with precision and efficiency. However, like any mechanical device, they can experience wear and tear, leading to reduced performance or even failure. To ensure longevity and reliable operation, many users turn to hydraulic ram rebuild kits. This article explores the importance of these kits, their components, and tips for effective installation.

What is a Hydraulic Ram Rebuild Kit?

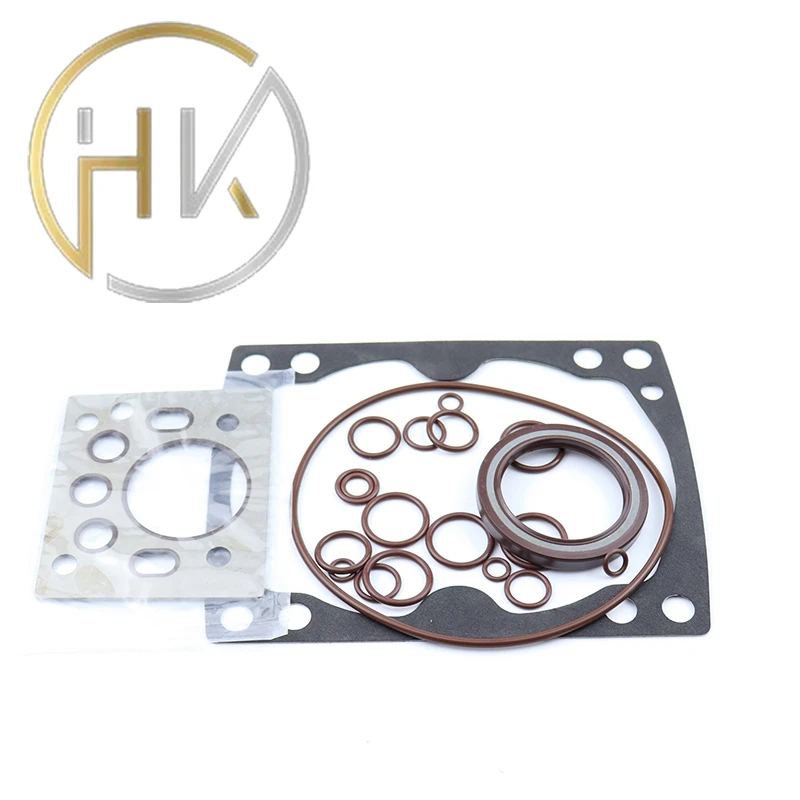

A hydraulic ram rebuild kit is a collection of parts designed to restore a hydraulic ram to its optimal working condition. These kits typically include essential components such as seals, o-rings, bearings, and piston rings. The specific contents of a rebuild kit may vary based on the type and model of the hydraulic ram, but the primary objective remains the same to repair and enhance the functionality of the ram.

Importance of Regular Maintenance

Regular maintenance of hydraulic rams is crucial to avoid catastrophic failures and ensure efficient operation. Over time, seals can degrade, leading to fluid leaks, which reduce the ram’s efficiency and can damage surrounding equipment. Additionally, contaminants can enter the hydraulic system, causing wear on internal components. By proactively using a rebuild kit, operators can prevent these issues, saving significant time and money on repairs or replacements.

Components of a Hydraulic Ram Rebuild Kit

1. Seals and O-Rings These components are crucial for preventing leaks and maintaining hydraulic pressure. They ensure that hydraulic fluid does not escape, preserving the efficiency of the system.

2. Piston Rings These rings provide a tight seal between the piston and the cylinder, preventing fluid bypass. This is vital for maintaining the ram's lifting capacity.

3. Bearings Bearings support the moving parts of the hydraulic ram, allowing for smooth operation. Worn bearings can lead to friction and ultimately a malfunction, making replacements essential.

4. Bushing The bushing serves as a protective layer between the ram and the cylinder, reducing wear and tear on both parts.

hydraulic ram rebuild kit

5. Fasteners Bolts, nuts, and screws are included to ensure that all parts are securely assembled. Using the right fasteners is essential for maintaining the integrity of the hydraulic system.

Installation Tips

Installing a hydraulic ram rebuild kit can be a straightforward process, but specific steps must be followed to ensure a successful rebuild

1. Preparation Before starting the rebuild, ensure that you have a clean workspace and all the necessary tools, including wrenches, screwdrivers, and a torque wrench.

2. Disassembly Carefully disassemble the hydraulic ram. Take note of the arrangement of parts, as this will aid in reassembly. Keeping the original components together can help identify which parts require replacement.

3. Inspection Before installing new components, inspect the hydraulic ram for any additional signs of wear or damage. Pay close attention to the cylinder’s interior and the ram’s exterior.

4. Cleaning Clean all surfaces thoroughly to remove any contaminants. This step is crucial to ensure that the new seals and components sit correctly.

5. Installation When installing new components from the rebuild kit, follow the manufacturer’s guidelines regarding order and torque specifications. Properly lubricate seals and o-rings before installation to ensure a good fit and extend their lifespan.

6. Testing After reassembly, it’s essential to test the hydraulic ram under operational conditions. Monitor for any leaks and ensure that the system operates smoothly.

Conclusion

Hydraulic ram rebuild kits are invaluable tools for maintaining and enhancing the performance of hydraulic rams. By understanding their components and following proper installation techniques, operators can ensure the longevity and efficiency of their hydraulic systems. Regular maintenance and timely rebuilds not only save costs in the long run but also enhance safety and productivity in various industrial applications. Investing in a quality rebuild kit is a small price to pay for the confidence and reliability it brings to hydraulic operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories