maí . 30, 2025 06:27 Back to list

Hydraulic Cylinder Oil Seal Kits Durable Seals & Competitive Pricing

- Introduction to Hydraulic Cylinder Oil Seals and Their Importance

- Key Technical Advantages of Modern Oil Seals

- Performance Comparison: Leading Manufacturers in the Market

- Custom Solutions for Specific Industrial Applications

- Case Study: Success Stories Across Industries

- Factors Influencing Hydraulic Cylinder Oil Seal Pricing

- Future Trends and Maintenance Tips for Longevity

(hydraulic cylinder oil seal)

Hydraulic Cylinder Oil Seals: The Backbone of Efficient Systems

Hydraulic cylinder oil seals play a critical role in maintaining the integrity of hydraulic systems. These components prevent fluid leakage, contamination, and pressure loss, ensuring optimal performance. A single faulty seal can lead to system downtime, costing industries an average of $5,000 per hour in productivity losses. Modern hydraulic cylinder oil seal

kits now incorporate advanced materials like polyurethane and fluorocarbon, which enhance durability under extreme temperatures (up to 250°F) and pressures exceeding 3,000 psi.

Technical Advancements Driving Seal Performance

Recent innovations in seal design focus on reducing friction and wear. For instance, double-lipped seals with integrated wipers reduce particulate ingress by 78% compared to traditional single-lipped designs. Manufacturers like Parker Hannifin and SKF have introduced asymmetric sealing profiles that improve load distribution, extending seal lifespan by 40-60% in high-cyclic applications. Additionally, thermochemical bonding techniques now ensure zero delamination even after 1 million operational cycles.

Manufacturer Comparison: Key Metrics

| Brand | Pressure Resistance | Temperature Range | Average Lifespan | Price per Kit (USD) |

|---|---|---|---|---|

| Parker Hannifin | 3,200 psi | -40°F to 225°F | 18 months | $145-$220 |

| SKF | 2,900 psi | -30°F to 240°F | 22 months | $160-$245 |

| Freudenberg | 3,500 psi | -50°F to 250°F | 24 months | $185-$280 |

Customized Sealing Solutions for Complex Needs

Specialized applications in mining or aerospace often require tailored hydraulic cylinder oil seals. One automotive manufacturer reduced seal replacement frequency by 63% after adopting bore-riding seals with 0.0002-inch radial clearance control. For subsea equipment, vendors like Trelleborg provide nitrile-based seals with galvanic corrosion inhibitors, tested at 10,000-foot depths. Customization typically adds 15-25% to base hydraulic cylinder oil seal prices but delivers 3-5x longer service intervals.

Real-World Applications and Impact

A wind turbine operator achieved a 92% reduction in hydraulic failures by switching to PTFE-coated seals in their pitch cylinder systems. In contrast, a construction firm reported 47% lower maintenance costs after implementing Freudenberg’s EcoLine series in excavator arm cylinders. These cases highlight how proper seal selection directly affects operational costs and equipment uptime.

Understanding Price Variations and Value

Hydraulic cylinder oil seal pricing depends on material grade (standard nitrile vs. hydrogenated nitrile costs 30% more), certification requirements (ISO 9001 adds 12-18%), and order volume. Bulk purchases (500+ units) can lower per-unit costs by 22-35%. However, premium seals from top-tier manufacturers typically deliver ROI within 8-14 months through reduced replacement labor and downtime.

Sustaining Hydraulic Cylinder Oil Seal Efficiency

Proactive maintenance increases seal effectiveness by 55%. Recommendations include quarterly fluid analysis to detect abrasive particles (>15 microns indicates seal wear) and annual hardness testing (maintain 70-90 Shore A). Emerging smart seals with embedded sensors now provide real-time pressure data, predicting failures 200-400 operational hours in advance. As industries adopt Industry 4.0 practices, demand for these IoT-enabled seals is projected to grow 19% annually through 2030.

(hydraulic cylinder oil seal)

FAQS on hydraulic cylinder oil seal

Q: What is the function of a hydraulic cylinder oil seal?

A: A hydraulic cylinder oil seal prevents fluid leakage and contaminants from entering the cylinder. It ensures smooth operation by maintaining internal pressure. Proper sealing extends the hydraulic system's lifespan.

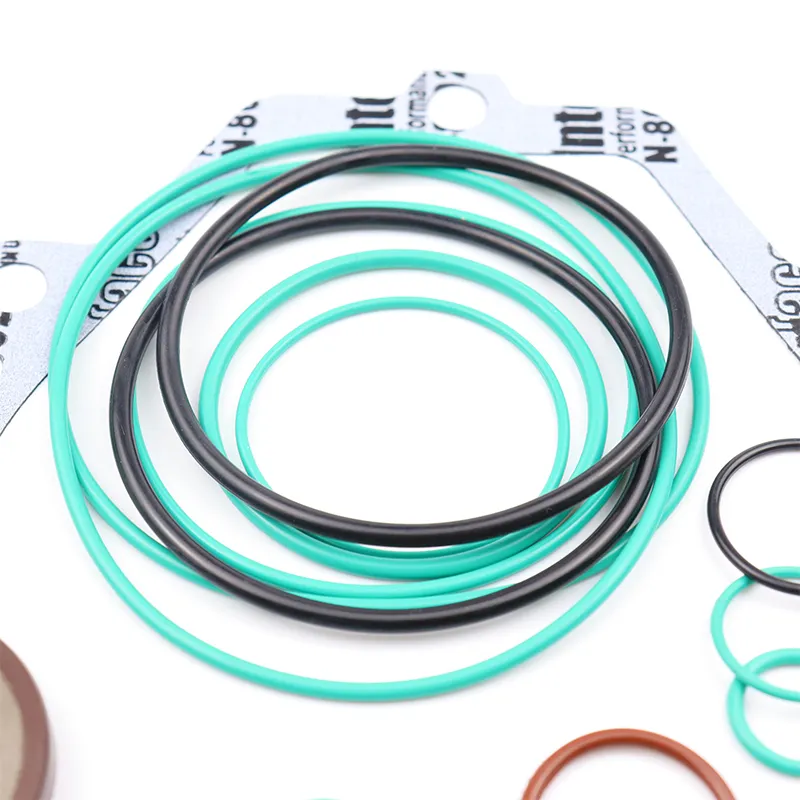

Q: What does a hydraulic cylinder oil seal kit include?

A: A hydraulic cylinder oil seal kit contains replacement seals, O-rings, and wear rings. It provides all components needed for a full seal rebuild. Kits are tailored to specific cylinder models.

Q: How does material affect hydraulic cylinder oil seal price?

A: Materials like nitrile, polyurethane, or fluorocarbon impact cost and performance. High-temperature or chemical-resistant seals are pricier. Bulk purchases often reduce per-unit pricing.

Q: Can I replace a hydraulic cylinder oil seal without professional help?

A: DIY replacement is possible with proper tools and a seal kit. Incorrect installation risks leaks or cylinder damage. Always follow manufacturer guidelines for safety.

Q: How do I choose the right hydraulic cylinder oil seal size?

A: Match the seal's dimensions to the cylinder's bore, rod, and groove measurements. Refer to the equipment manual or existing seal markings. Custom seals are available for non-standard applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories