nóv . 23, 2024 13:10 Back to list

high pressure shaft seals

Understanding High Pressure Shaft Seals Key Components in Modern Machinery

High pressure shaft seals play a crucial role in ensuring the efficiency and safety of various mechanical systems within industrial applications. Shaft seals are designed to prevent the leakage of fluids, whether they be liquids or gases, from the rotating shafts of machinery. As industries move towards higher pressures and more demanding operational environments, the need for reliable high pressure shaft seals has never been greater.

Importance of High Pressure Shaft Seals

These seals are particularly important in offshore drilling, oil and gas processing, chemical manufacturing, and similar sectors where high-pressure equipment encounters extreme conditions. A high pressure shaft seal prevents not only fluid leaks but also ingress of contaminants that could compromise the integrity of the machinery. Without effective seals, the risk of equipment failure increases, potentially leading to costly downtime, environmental hazards, and safety risks for personnel.

Design and Materials

The design of high pressure shaft seals must accommodate the specific demands of their operational environment. Commonly constructed from materials like elastomers, PTFE (polytetrafluoroethylene), metal, or composite materials, these seals are engineered to withstand not just pressure, but also temperature fluctuations and chemical exposure. The choice of material is critical; for instance, PTFE seals are renowned for their chemical resistance, while elastomers may offer greater flexibility.

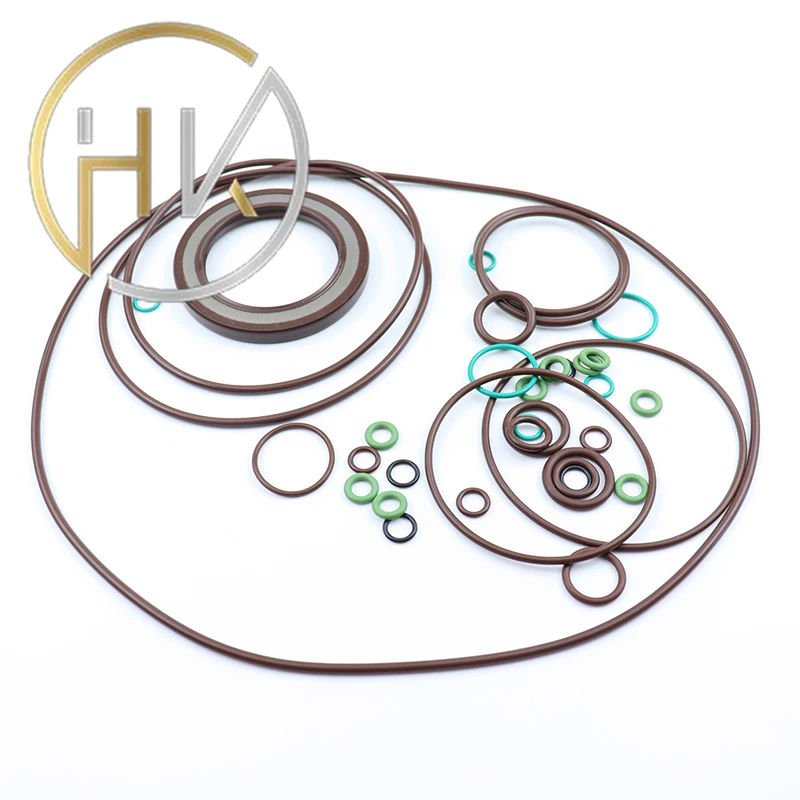

Types of High Pressure Shaft Seals

There are several types of high pressure shaft seals, each designed for different applications

. Common types includehigh pressure shaft seals

1. Mechanical Seals Often used in pumps and compressors, these seals consist of two primary components that rotate with the shaft, forming a tight barrier against fluid leakage.

2. lip Seals These seals feature a flexible lip that conforms to the surface of the shaft, providing effective sealing against minor misalignments and surface imperfections.

3. O-Ring Seals Simple yet effective, O-rings can be used in bolted connections and hollow shafts to prevent leakage under pressure.

Selecting the right type of seal depends on various factors, including the pressure differential, temperature range, and the nature of the fluid being sealed.

Installation and Maintenance

Proper installation is pivotal to the performance of high pressure shaft seals. Misalignment, improper torque, or contamination during installation can lead to premature seal failure. Regular maintenance is equally important; monitoring for signs of wear or leakage can help identify potential issues before they escalate into significant problems.

Conclusion

In conclusion, high pressure shaft seals are indispensable components in many high-stakes industrial applications. Their ability to prevent leaks under challenging conditions helps maintain the reliability and efficiency of machinery. As technology advances, ongoing research and development in materials and designs will continue to enhance the performance and longevity of these seals, ultimately contributing to safer and more efficient industrial operations. Understanding the significance of these seals and their proper maintenance can make a substantial difference in the successful operation of various processes across myriad industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories