des . 25, 2024 15:11 Back to list

Optimizing High-Pressure Shaft Design for Enhanced Performance and Durability in Engineering Applications

Understanding High Pressure Shafts An Essential Component in Modern Engineering

In the realm of mechanical engineering, high pressure shafts play a vital role in various applications, from aerospace to energy generation. These shafts are designed to withstand extreme pressure conditions, ensuring the efficient functioning and durability of machinery. As industries push the boundaries of technology and performance, the demand for high pressure shafts has surged, prompting a closer examination of their design, materials, and applications.

What is a High Pressure Shaft?

A high pressure shaft is a cylindrical mechanical component that transmits power and rotation under high pressure conditions. Typically made from high-strength materials such as steel or titanium, these shafts are engineered to support high loads while minimizing deformation and failure risks. Applications that require high pressure shafts include hydraulic systems, turbines, compressors, and various types of industrial machinery.

Design Considerations

The design of high pressure shafts is critical to their performance and longevity. Engineers must account for several factors, including material strength, shaft diameter, length, and operating conditions. The material selection is particularly crucial; it needs to possess excellent tensile strength, fatigue resistance, and corrosion resistance. For instance, in environments where the shaft may be exposed to corrosive substances, stainless steel or specialized alloys may be used.

Moreover, the shaft's surface finish and any necessary coatings should be considered to reduce friction and enhance durability. Precision machining techniques ensure tight tolerances, which are essential for shafts operating in high-pressure environments. Any deviations from the specified dimensions can lead to operational inefficiencies and increase the risk of catastrophic failure.

Manufacturing Processes

The manufacturing process of high pressure shafts often involves advanced techniques such as forging, machining, and surface treatment. Forging enhances the material's grain structure, resulting in improved strength and toughness. After forging, the shafts are typically machined to achieve precise dimensions and surface qualities.

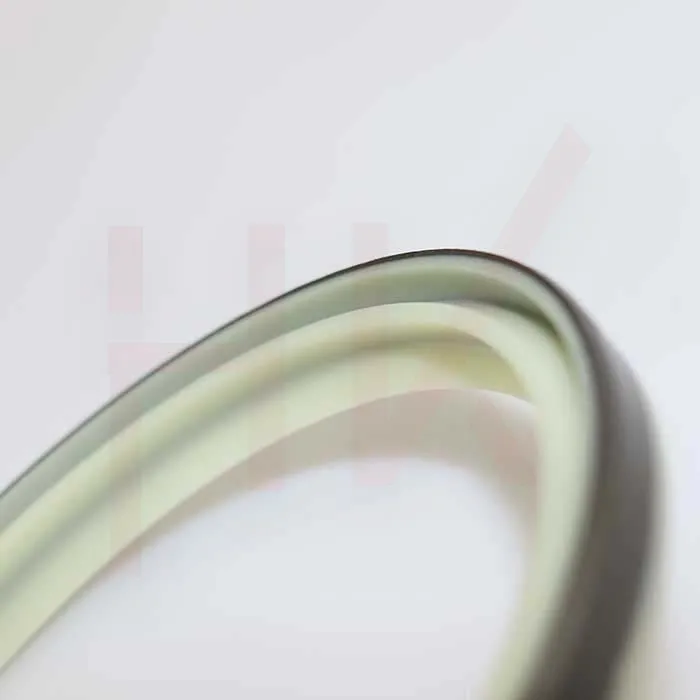

high pressure shaft

Heat treatment processes may also be employed to further enhance the mechanical properties of the material. This can include quenching and tempering processes that increase hardness while maintaining ductility, which is crucial to withstand the repeated stress of high-pressure operations.

Applications in Various Industries

High pressure shafts find applications across a broad spectrum of industries. In aerospace engineering, they are used in engines that need to operate under extreme pressure and temperature conditions. Turbomachinery, such as gas turbines, relies heavily on high pressure shafts to efficiently convert energy from fuel into mechanical power.

In the energy sector, these shafts are integral to the operation of hydroelectric turbines and gas compression systems. Their capacity to handle high pressures makes them ideal for applications where safety and reliability are paramount. The automotive industry also utilizes high pressure shafts in various components, including turbochargers and superchargers, which enhance engine performance by increasing the intake of air.

Challenges and Future Directions

Despite their robustness, high pressure shafts are not without challenges. The increasing demands for efficiency and performance in modern machinery call for continuous innovation in materials and design. Researchers and engineers are exploring advanced materials, such as composites and newer alloys, that offer even higher strength-to-weight ratios.

Moreover, advancements in manufacturing techniques, including additive manufacturing (3D printing), present promising avenues for producing high pressure shafts with complex geometries that were previously challenging to achieve. This technology allows for greater design flexibility and can lead to enhanced performance characteristics.

Conclusion

High pressure shafts are essential components in a multitude of engineering applications, serving as the backbone of complex machinery that demands reliability and performance. As technological advancements continue to shape various industries, ongoing research and innovation in the design, materials, and manufacturing of high pressure shafts will be crucial. Future developments promise not only to enhance their capabilities but also to contribute to the sustainability and efficiency of engineering solutions across the globe. Through diligent engineering practices and innovative thinking, the role of high pressure shafts will undoubtedly continue to evolve, reinforcing their importance in modern technology.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories