nóv . 26, 2024 06:28 Back to list

Understanding Gearbox Oil Seals and Their Importance in Vehicle Maintenance

Understanding Gearbox Oil Seals Function, Importance, and Maintenance

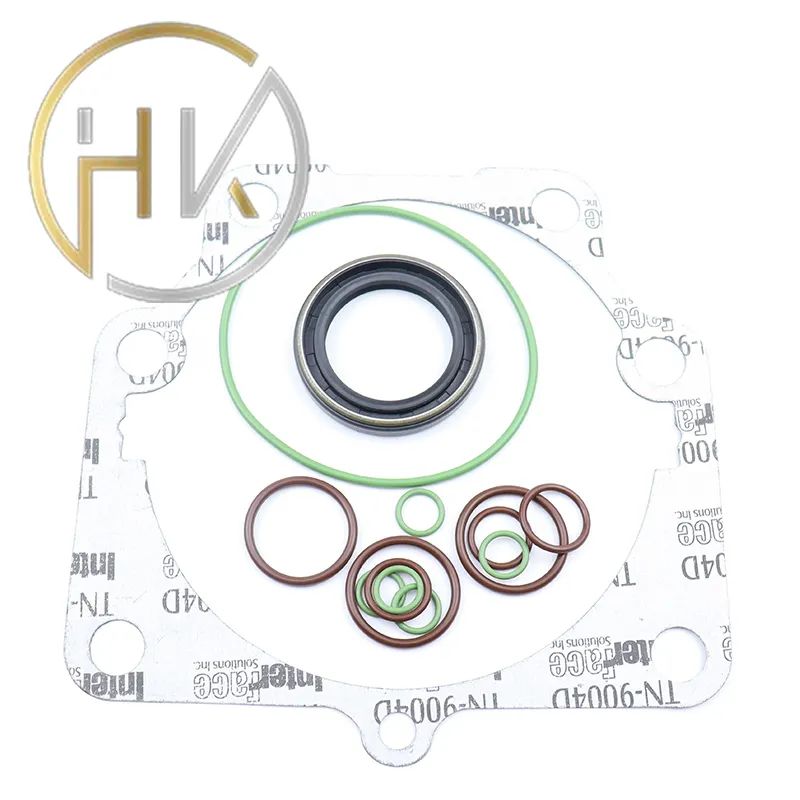

Gearbox oil seals play a crucial role in ensuring the efficient operation of various machinery, particularly in automotive and industrial applications. These components are designed to prevent the leakage of lubricants while keeping contaminants out of the gearbox, ultimately ensuring smooth gear operation and extending the lifespan of the equipment.

What is a Gearbox Oil Seal?

A gearbox oil seal is a mechanical component that provides a barrier between the moving parts of the gearbox and the external environment. Typically made from rubber, elastomers, or synthetic materials, these seals are engineered to withstand various operational stresses, including temperature fluctuations, pressure changes, and exposure to chemicals. They are placed at the junctions of the gearbox housing and the rotating shafts to minimize oil leakage and to prevent dirt, dust, and debris from entering the gearbox mechanism.

Importance of Gearbox Oil Seals

The significance of gearbox oil seals cannot be overstated. They serve several key functions

1. Leak Prevention The primary purpose of an oil seal is to prevent the loss of lubricant. A significant loss of gearbox oil can lead to inadequate lubrication, resulting in increased friction and heat, which can ultimately cause gear failure.

2. Contamination Control Oil seals also function as a barrier against contaminants. Dirt, debris, and moisture can severely impact the internal components of a gearbox, leading to corrosion and wear. By sealing off the internal environment, these seals help maintain the purity of the lubricant and the integrity of the gearbox.

gear box oil seal

3. Enhanced Performance Properly functioning oil seals contribute to the overall performance of machinery. When gears are adequately lubricated and free from contaminants, they can operate more smoothly and efficiently. This translates to better fuel economy in vehicles and improved productivity in industrial machinery.

4. Cost Savings By preventing oil leaks and contamination, gearbox oil seals can help save money in the long run. Reduced maintenance costs, fewer repairs, and longer intervals between servicing are all benefits of maintaining effective seals.

Maintenance and Replacement

To ensure that gearbox oil seals perform efficiently, regular maintenance checks should be conducted. Signs of a failing oil seal can include oil stains around the gearbox, unusual noises from the gearbox area, or decreased performance. If these symptoms are observed, it's essential to address the issue promptly.

When replacing oil seals, it's crucial to select the right type compatible with the specific gearbox. Manufacturers often provide specifications regarding the type of material and seal design suitable for their machines. Installing the correct seal ensures a proper fit and optimal performance.

During installation, care should be taken not to damage the seal or the sealing surfaces. Proper alignment and the use of appropriate tools can prevent damage that could lead to further issues down the line.

Conclusion

In summary, gearbox oil seals are vital components that protect against oil leaks and contamination, significantly affecting machinery performance and longevity. Regular maintenance and timely replacement are essential to ensure these seals function effectively. By understanding the importance of gearbox oil seals, operators can safeguard their equipment and maintain efficient operations, ultimately leading to better performance and reduced costs.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories