okt . 04, 2024 12:07 Back to list

25x35x7mm Oil Seal Specifications and Applications for Mechanical Systems

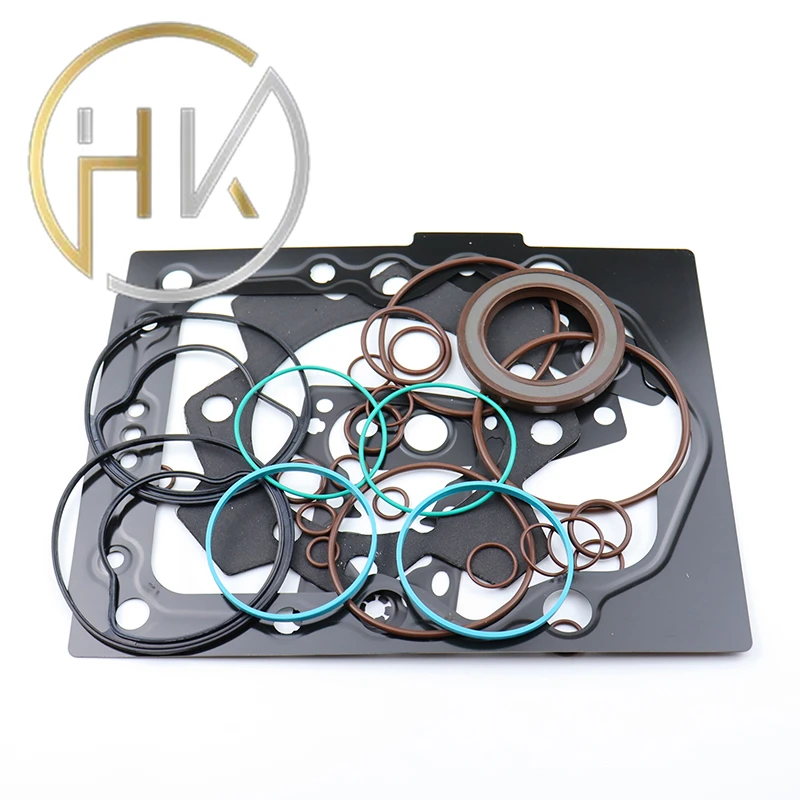

Understanding the 25x35x7 Oil Seal Specifications and Applications

Oil seals are crucial components in various mechanical systems, serving as barriers to prevent the leakage of lubricants and contaminants. One of the commonly used sizes in different applications is the 25x35x7 oil seal, which signifies the seal's inner diameter (25 mm), outer diameter (35 mm), and width (7 mm). This article delves into the specifications, materials, and applications of the 25x35x7 oil seal, highlighting its significance in the maintenance of mechanical integrity.

Specifications

The dimensions of the 25x35x7 oil seal are essential for compatibility with various equipment. The inner diameter of 25 mm allows it to fit on shafts or axles that measure 25 mm in diameter. The outer diameter of 35 mm makes it suitable for components with corresponding housing sizes. The width of 7 mm provides adequate sealing surface area, ensuring effective sealing capabilities.

Oil seals can be designed for different pressure ratings, often determined by the specific application in which they are utilized. A well-designed oil seal should be capable of resisting pressure fluctuations while maintaining its integrity over time. In many applications, seals made with higher-grade materials can withstand harsher conditions and resist wear better than standard seals.

Materials

The material composition of oil seals significantly influences their durability and performance. Common materials include

1. Nitrile Rubber (NBR) This is a popular choice for oil seals due to its excellent resistance to petroleum-based oils, water, and temperature variations. NBR seals can operate effectively in temperatures ranging from -30°C to 100°C, making them suitable for many automotive and industrial applications.

25x35x7 oil seal

2. Fluoroelastomer (FKM) For applications requiring high temperature and chemical resistance, FKM seals are preferred. They can operate in extreme temperature ranges, often exceeding 200°C, making them suitable for more demanding environments, such as those involving aggressive chemicals.

3. Polyurethane (PU) Known for its good abrasion resistance, PU oil seals are utilized in applications that involve motion or high wear. Their flexibility and toughness make them an excellent choice for dynamic sealing situations.

4. Silicone Silicone seals can withstand high temperatures and are often used in applications where food-grade or non-toxic materials are required. Their ability to maintain performance over a wide temperature range makes them versatile for various uses.

Applications

The 25x35x7 oil seal finds applications across multiple industries. In automotive settings, these seals are often used in engines, transmissions, and differentials to prevent oil leakage, ensuring that the machinery operates efficiently and without interruption. In industrial machinery, oil seals protect bearings and gears, preventing contamination from dust and moisture, and extending the lifespan of these components.

Moreover, the 25x35x7 oil seal is indispensable in the lubrication system of hydraulic machinery, where maintaining fluid integrity is paramount. These seals also make their way into household appliances like washing machines and vacuum cleaners, where they contribute to the overall functionality of mechanical seals within pumps and motors.

Conclusion

The 25x35x7 oil seal is a vital component in various mechanical applications, serving the essential purpose of preventing fluid leakage and protecting internal parts from contaminants. Understanding its specifications and material properties can help engineers and technicians choose the right seal for their specific needs, ultimately enhancing the reliability and longevity of their equipment. As technology continues to advance, the designs and materials used in oil seals will likely evolve, further improving their performance in a wide range of applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories