Nov . 16, 2024 20:39 Back to list

Alternative Options for Rubber Wiper Seals in Automotive Applications

The Importance of Rubber Wiper Seals in Various Applications

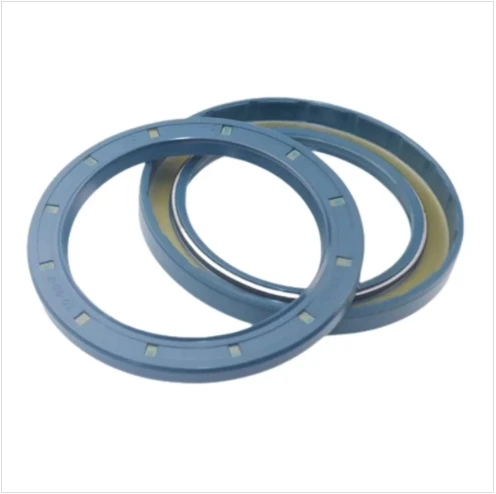

Rubber wiper seals are essential components utilized across a wide range of industries, from automotive to industrial machinery. These seals play a critical role in maintaining equipment efficiency and extending the lifespan of various devices by preventing contaminants from entering critical areas.

Functionality and Design Rubber wiper seals are designed to wipe away debris, dirt, and moisture from surfaces, ensuring a cleaner and more efficient operation. Their primary function is to protect underlying components, such as bearings and shafts, from the damaging effects of foreign particles. The design of these seals is particularly important; they are typically made from high-quality rubber compounds that provide flexibility, durability, and resistance to various environmental factors. This versatility allows them to perform effectively even in the harshest conditions.

Applications in Automotive Industry In the automotive sector, rubber wiper seals are commonly found around windshields, windows, and doors to prevent water leakage and reduce wind noise. They are also used in components like brake calipers and suspension systems, where they help ensure optimal performance by keeping lubricants intact and preventing dirt ingress. Their role is crucial as it directly affects driver safety and comfort.

rubber wiper seal

Industrial Machinery and Equipment Beyond automotive uses, rubber wiper seals are extensively employed in industrial machinery. For instance, hydraulic cylinders use these seals to maintain pressure while keeping contaminants at bay. In manufacturing environments, equipment such as CNC machines depend on wiper seals to ensure smooth operation and reduce wear on moving parts. The reliability of these seals can significantly impact production efficiency and maintenance costs.

Choosing the Right Seal When selecting rubber wiper seals, several factors must be considered, including the operating environment, the types of fluids involved, and the temperature ranges. The right choice of materials and design can enhance performance and longevity. For instance, seals made from silicone or nitrile rubber are often chosen for their exceptional resistance to heat and chemicals, making them ideal for various applications.

Conclusion Rubber wiper seals may seem like small components, but their importance in protecting equipment cannot be overstated. They enhance the reliability and efficiency of automotive and industrial applications alike. As technology evolves and demands for performance increase, the development of advanced rubber wiper seals will continue to play a crucial role in innovation, ensuring that equipment operates smoothly and efficiently for years to come. Understanding their significance allows industries to make informed decisions that lead to better maintenance and improved operational success.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories