Feb . 13, 2025 10:20 Back to list

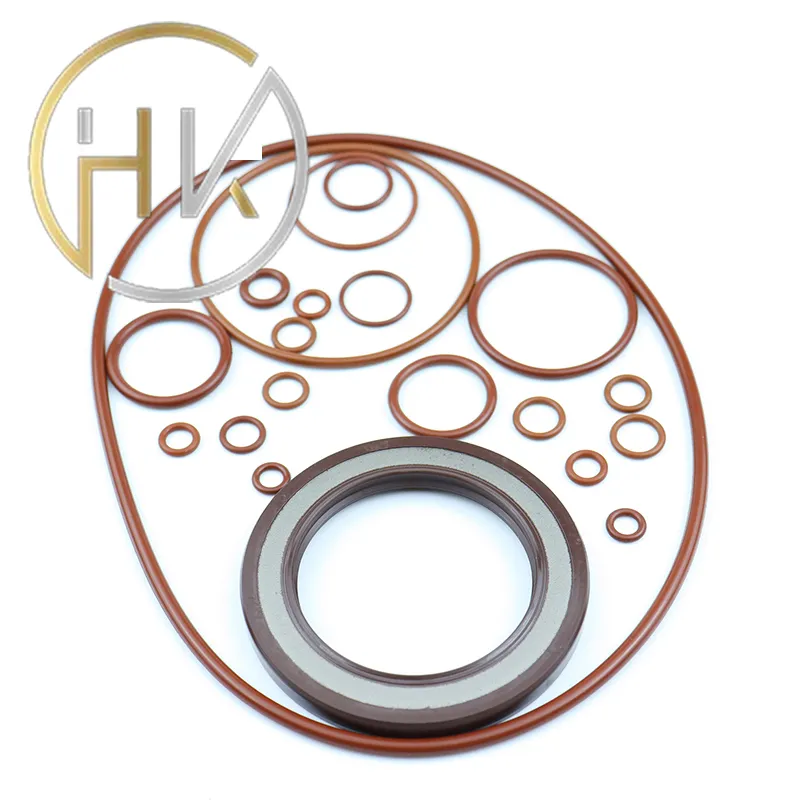

double lip oil seal

The authoritativeness of double lip oil seals in the field is highlighted by their widespread adoption across various industries. From automotive engines, where they help maintain the integrity of complex engine systems, to heavy machinery used in construction, the reliable performance of these seals can be credited with significantly improving machinery efficiency. Trustworthiness in the realm of double lip oil seals comes from both the quality of the product and the reputation of the manufacturer. Companies producing these seals must adhere to stringent manufacturing processes and quality control measures. Regular testing and adherence to international standards ensure that every seal meets the required performance criteria, thus preserving the equipment's operational reliability. For industries seeking to optimize their machinery's performance, investing in high-quality double lip oil seals is a strategic decision. These seals not only safeguard the operational environment but also contribute to environmental sustainability by preventing the leakage of harmful substances. In conclusion, double lip oil seals are an essential component in the maintenance and efficient operation of machinery across multiple sectors. Through their expert design, authoritative usage, and trustworthy performance, these seals provide an invaluable service to industries globally. Businesses that prioritize reliable machinery performance and maintenance efficiency will find that these seals are an invaluable investment in their operational infrastructure.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories