Sep . 30, 2024 21:39 Back to list

3 Ton Hydraulic Jack Seal Repair Kit for Efficient Performance and Longevity

Understanding the 3 Ton Hydraulic Jack Seal Kit

Hydraulic jacks are vital tools used across various industries and applications, primarily for lifting heavy loads with minimal effort. Among these tools, the 3-ton hydraulic jack is a popular choice for automotive repair, construction, and home maintenance tasks. To ensure the optimal performance and longevity of a hydraulic jack, regular maintenance and timely replacement of worn components, such as seals, are essential. This is where a 3-ton hydraulic jack seal kit comes into play.

What is a Hydraulic Jack Seal Kit?

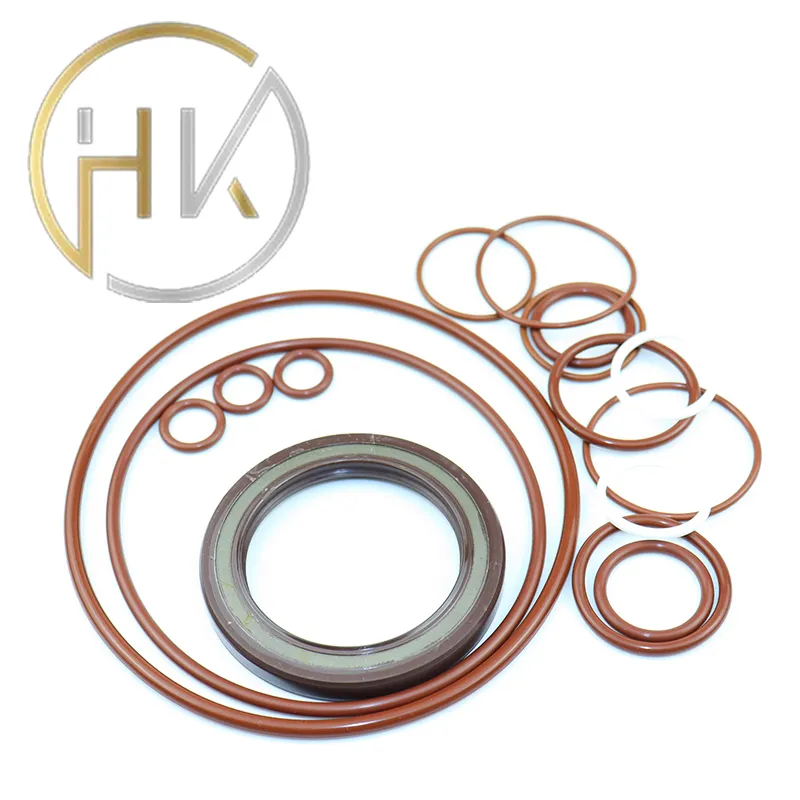

A hydraulic jack seal kit is a collection of various seals and O-rings designed specifically for hydraulic jacks. These seals are critical in maintaining the hydraulic system's integrity by preventing fluid leaks and ensuring that the hydraulic pressure remains contained. A seal kit typically includes components such as

1. Piston Seals These seals are placed around the piston to prevent hydraulic fluid from leaking out during operation. 2. Wiper Seals These are used to clear debris and contaminants from the piston rod, preventing damage to the hydraulic system. 3. Backup Rings Used in conjunction with O-rings, they provide additional support and help maintain a secure seal under pressure. 4. O-Rings Essential for sealing connections and preventing leaks at various joints within the hydraulic system.

Importance of Regular Maintenance

Regular maintenance of your hydraulic jack is crucial to ensure it operates safely and efficiently. Over time, seals can wear out due to constant pressure, friction, and exposure to harsh environmental conditions. When seals degrade, they can lead to fluid leaks, which not only diminish the jack’s lifting capacity but may also pose safety risks, such as loss of control when lifting heavy objects.

By investing in a 3-ton hydraulic jack seal kit, you can perform routine maintenance on your hydraulic jack, extending its lifespan and saving money in the long run. Replacing worn seals restores the jack’s performance, allowing it to function effectively for various lifting tasks.

How to Replace Seals in a Hydraulic Jack

3 ton hydraulic jack seal kit

Replacing seals in a hydraulic jack may seem daunting, but with the right tools and guidance, it can be a straightforward process

. Here’s a simple step-by-step guide1. Disassemble the Jack Start by removing the jack from its supporting structure. Use appropriate tools to disassemble the jack, paying close attention to how components fit together. Take pictures if necessary to aid reassembly.

2. Remove Old Seals Carefully extract the old seals using a seal puller or a flathead screwdriver. Be gentle to avoid damaging the housing.

3. Clean the Components Use a clean, lint-free cloth to wipe down all components of the jack. Ensure that the sealing surfaces are free of debris, dirt, and hydraulic fluid.

4. Install New Seals Follow the instruction manual for your specific hydraulic jack model to install the new seals. Make sure each seal fits snugly into its designated groove.

5. Reassemble the Jack Once the new seals are in place, reassemble the hydraulic jack, ensuring that all components are securely fastened.

6. Test the Jack Before putting the jack back into regular use, conduct a test to ensure that it is operating correctly and that there are no leaks.

Conclusion

A 3-ton hydraulic jack seal kit is an essential investment for anyone who relies on hydraulic lifting equipment. Regularly maintaining your jack with fresh seals will not only enhance its performance but also ensure safety while handling heavy loads. With a little patience and effort, replacing seals can be a rewarding DIY project, saving you the cost of professional repairs and extending the life of your hydraulic jack. Remember, proper care leads to effective lifting solutions and enhanced productivity in all your tasks.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories