Jan . 24, 2025 03:17 Back to list

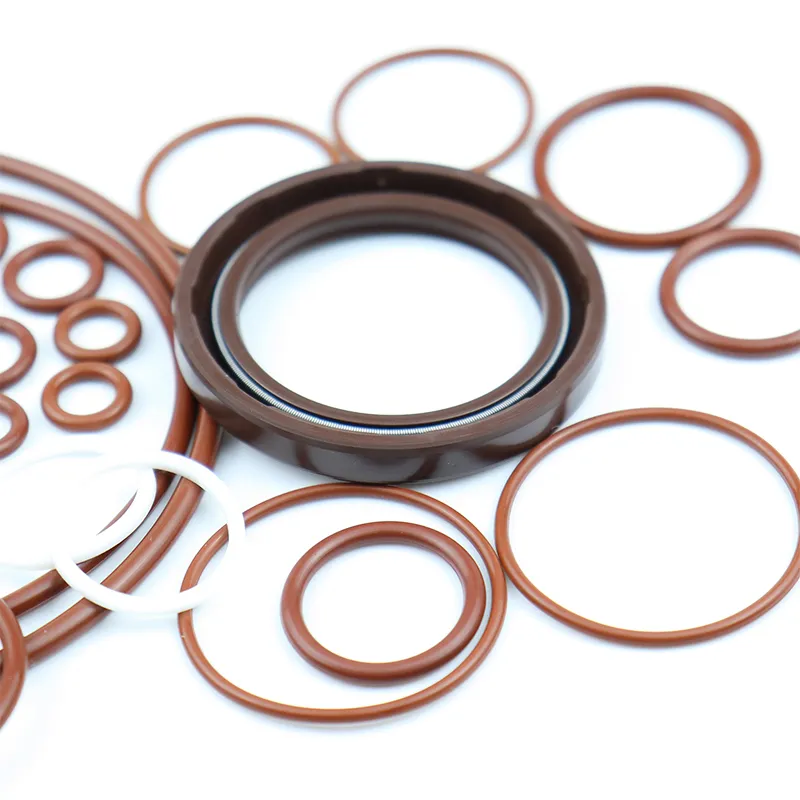

cylinder packing kits

The credibility of cylinder packing kits is further reinforced through rigorous quality control and adherence to international standards. Manufacturers who adhere to ISO certifications offer an additional layer of assurance to consumers, ensuring that each kit meets stringent guidelines for quality and reliability. This adherence not only boosts consumer confidence but also strengthens the reputation of manufacturers as leaders in the field. In an ever-evolving technological landscape, cylinder packing kits are also seeing advancements. Innovations such as self-lubricating seals and eco-friendly materials are beginning to take center stage, appealing to a growing market focused on sustainability. Experts predict that as technology advances, the integration of smart sensors that monitor seal condition could revolutionize preventative maintenance, a development eagerly anticipated by industry professionals. For consumers seeking cylinder packing kits, it is paramount to ensure that suppliers are reputable and transparent about the materials and testing procedures employed. Establishing trust through open communication and verified testimonials can significantly impact buyer confidence. Additionally, consulting with field experts or engaging in professional forums can provide invaluable insights, ensuring that the selected kits not only meet technical specifications but also align with broader operational goals. To conclude, cylinder packing kits are more than mere components; they are critical to operational excellence across many industries. Their role in ensuring system integrity, reducing environmental impact, and improving cost-efficiency cannot be overstated. As we invest in these components, we not only secure the reliability of our machines but also pave the way for future innovations that promise even greater efficiency and sustainability. Trust in these kits is well-placed, grounded in a foundation of expertise, experience, and a commitment to excellence.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories