Հկտ . 16, 2024 03:31 Back to list

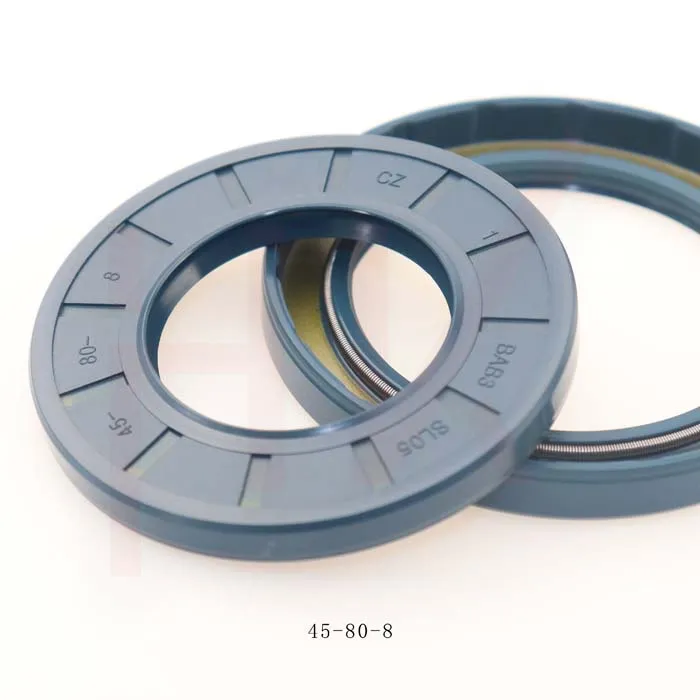

hydraulic wiper seal

Understanding Hydraulic Wiper Seals Essential Components for Fluid Power Systems

Hydraulic systems are crucial in various industries, ranging from construction to manufacturing, due to their effectiveness in transmitting power through fluid movement. One of the critical components that ensure the efficiency and longevity of hydraulic systems is the hydraulic wiper seal. These seals play a vital role in maintaining the integrity of hydraulic cylinders and preventing contamination from external environments.

What are Hydraulic Wiper Seals?

A hydraulic wiper seal is a sealing device designed to wipe away contaminants from the rod of a hydraulic cylinder as it extends and retracts. Positioned at the outer end of the cylinder, it acts as the first line of defense against dust, dirt, and moisture, which can significantly affect the performance of hydraulic machinery. The primary objective of a wiper seal is to protect the internal components of the hydraulic system, ensuring that the hydraulic fluid remains clean and uncontaminated.

Functionality and Importance

The functionality of hydraulic wiper seals is critical in preventing premature wear of the cylinder's internal surfaces and maintaining the system's overall efficiency. By effectively removing debris during the rod's movement, wiper seals minimize the risk of scratches and other forms of damage that can lead to hydraulic leaks or failures. This is particularly vital in heavy-duty applications where equipment is subjected to harsh working conditions.

hydraulic wiper seal

Moreover, hydraulic wiper seals contribute to the system's overall reliability and operational safety. A well-functioning seal reduces maintenance costs and downtime, resulting in significant savings for businesses over time. By preventing leaks and maintaining fluid integrity, wiper seals enhance the performance and lifespan of hydraulic components.

Materials and Design

Hydraulic wiper seals are typically made from various elastomeric materials, such as nitrile rubber (NBR), polyurethane (PU), or fluorocarbon (FKM), depending on the specific application and operational conditions. These materials are chosen based on their resistance to wear, temperature extremes, and compatibility with the hydraulic fluids being used.

The design of wiper seals can vary to accommodate different cylinder types and operational requirements. Factors such as the seal’s geometry, lip design, and preload affect its wiping efficiency and performance. Advanced designs also include features that enhance fluid management and improve sealing longevity.

Conclusion

In conclusion, hydraulic wiper seals are indispensable components of hydraulic systems, playing a critical role in enhancing system performance, reliability, and longevity. Understanding their function, design, and materials is essential for anyone involved in the maintenance or operation of hydraulic machinery. By prioritizing the integrity of these seals, industries can ensure efficient operations, minimize downtime, and achieve overall cost savings, solidifying the importance of these seemingly minor yet essential components within fluid power systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories