Հնվ . 10, 2025 08:17 Back to list

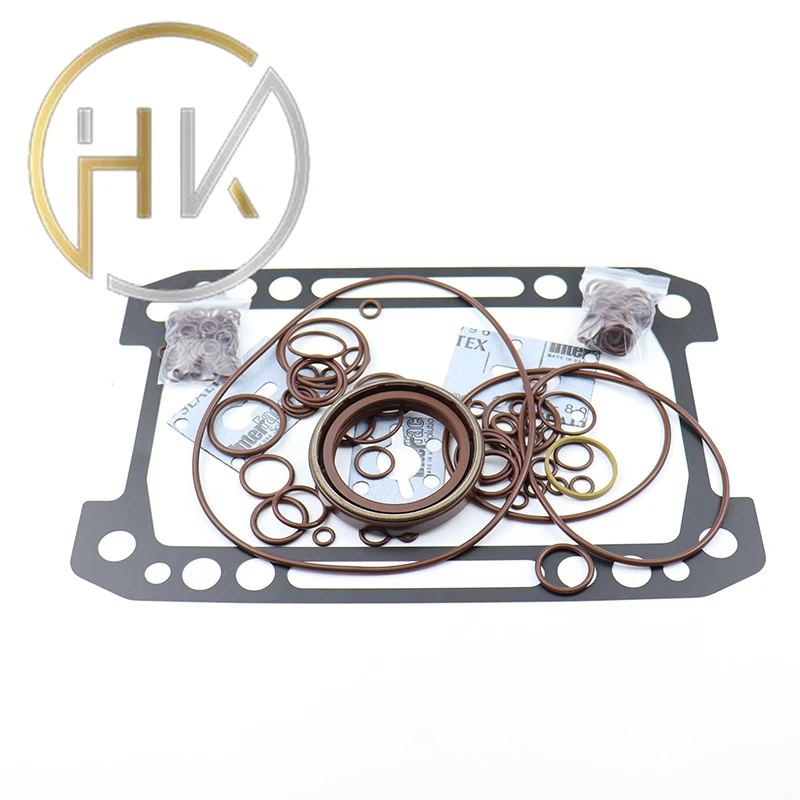

double lip oil seal

Furthermore, materials used in double lip oil seals are diverse, often including Nitrile (NBR), Polyacrylate (ACM), or Fluoroelastomer (FKM), each offering distinct properties that cater to different operational environments. Nitrile, for instance, is celebrated for its excellent resistance to oil and operating temperatures ranging from -40°C to 120°C, while Fluoroelastomer is preferred for high-temperature applications where temperatures might soar up to 250°C. When sourcing double lip oil seals, relying on well-established manufacturers with a track record for quality and innovation ensures trustworthiness. Such manufacturers often employ cutting-edge technology and rigorous quality control processes to guarantee seals that meet stringent standards and have set benchmarks for performance. Meeting these stringent standards not only instills trust but also positions the product as a reliable solution in the marketplace. As machinery and equipment become more advanced, the demand for components that can adapt and offer enduring solutions is more critical than ever. In conclusion, double lip oil seals stand as a testament to modern engineering advancements, offering both enhanced protection and efficiency. Their unique design, coupled with thorough expertise-driven choices in material and precise installations, delivers unmatched operational benefits. By emphasizing the role of expertise and trust in the selection and maintenance of double lip oil seals, businesses can achieve sustained success and operational excellence in their machinery performance.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories