Դկտ . 12, 2024 16:53 Back to list

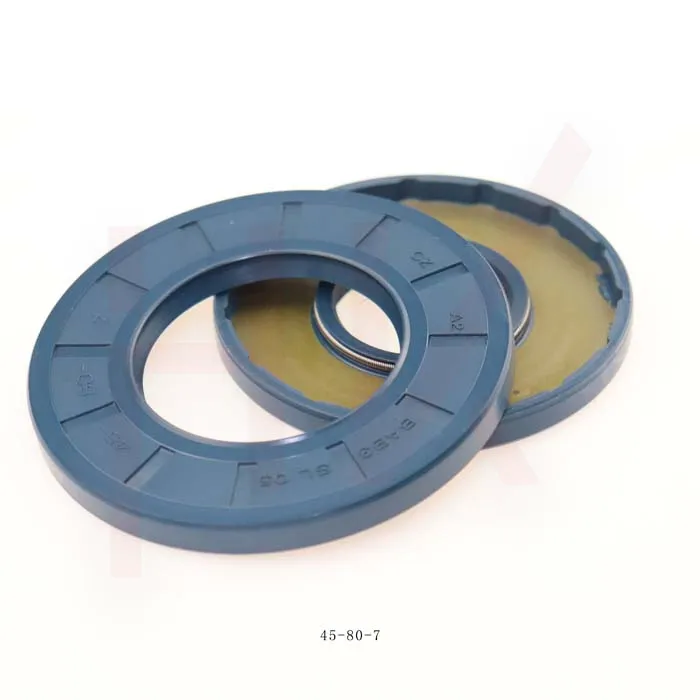

22 40 7 oil seal

The Role of Oil Seals in Industrial Applications

In the realm of mechanical engineering and industrial applications, the importance of components designed to contain and protect mechanical systems cannot be overstated. One such crucial component is the oil seal. Specifically, understanding a component that operates efficiently at 22%, 40%, and 7% of its design capacity is vital for various applications in the industry.

Oil seals, also known as grease seals, serve a fundamental role in preventing the leakage of lubricants while keeping contaminants such as dirt, dust, and moisture out of machinery. This protective function is essential for ensuring the longevity and efficiency of mechanical systems. In various industries, oil seals can be subjected to varying operational conditions. For instance, an oil seal that operates effectively at 22% of its capacity may be utilized in light-duty applications where pressures and speeds are low, such as small electric motors or household appliances.

The Role of Oil Seals in Industrial Applications

When it comes to operation at 40%, oil seals are often engaged in more demanding applications where machinery faces higher loads and rotational speeds. This is typical in automotive and aerospace engineering where components such as gearboxes, transmissions, and hydraulic systems are regularly found. The ability of an oil seal to withstand considerable pressure while maintaining a robust seal is vital. The materials used in fabricating these seals are crucial in this regard; rubber compounds, for example, are commonly employed due to their resilience and adaptability to various lubricant types.

22 40 7 oil seal

Moreover, operating conditions can vary significantly, and oil seals need to be tailored to address these variations. For example, temperature fluctuations and the presence of aggressive chemicals can deteriorate seals. In applications operating around 40%, where conditions may increase wear and tear, selecting the correct seal material and design should be based on environmental factors, media compatibility, and mechanical load. Advanced materials like Viton and PTFE are commonplace for seals that endure harsh conditions.

The 7% application refers to cases where oil seals operate under considerably lower loads, such as in low-speed applications or those requiring minimal lubrication. Understanding the performance capabilities and limitations of oil seals at this level is critical for designing systems that will run efficiently without unnecessary wear. Transitioning from high to low application loads requires careful consideration of seal design to prevent issues such as sticking or excessive clearance that could lead to failures.

The versatility of oil seals allows them to be implemented across a wide range of industries, from automotive to manufacturing and pharmaceuticals. Their ability to adapt and perform efficiently under varying load capacities (22%, 40%, and 7%) showcases not only their fundamental engineering significance but also innovation in materials and design.

In conclusion, oil seals are indispensable components that play a vital role in maintaining machine efficiency and reliability. Their capacity to perform across different operational levels—from light-duty applications at 22%, through standard operations at 40%, down to low-load scenarios at 7%—highlights the necessity for engineers to select the appropriate type and design based on specific operational conditions. As industrial applications continue to evolve, the development of more advanced and resilient oil seals will remain crucial to ensure operational efficiency, safety, and sustainability across various sectors.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories