nov . 17, 2024 19:59 Back to list

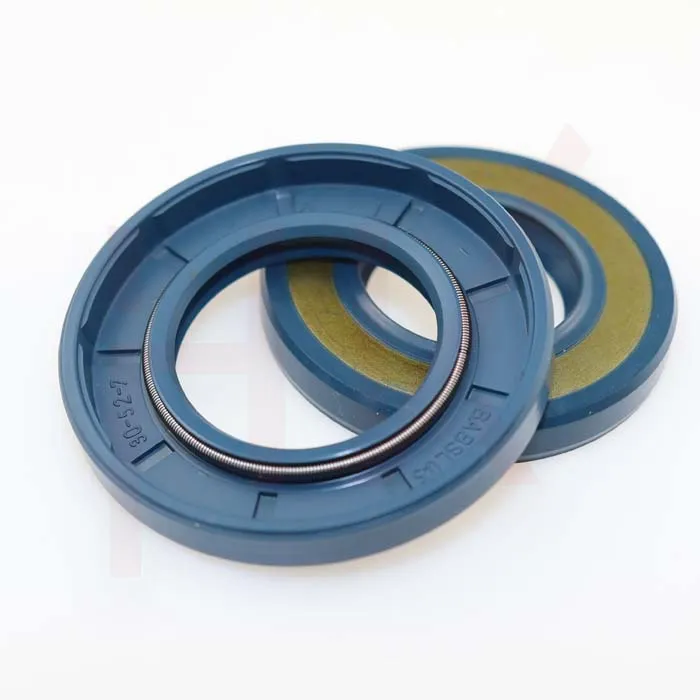

oil wiper ring

Understanding Oil Wiper Rings Importance, Functions, and Applications

Oil wiper rings are crucial components in various machinery and engines, primarily designed to manage lubrication and minimize oil consumption. These rings serve an essential function in ensuring the optimum performance of engines, particularly in internal combustion engines found in automobiles, machinery, and other equipment. This article explores the significance of oil wiper rings, their working mechanism, and their various applications across different industries.

What are Oil Wiper Rings?

Oil wiper rings, also known as oil scraper rings, are a type of sealing device used in engines and other equipment to control the amount of oil that comes into contact with moving parts. They are typically located on the piston of an engine, positioned above the compression rings. Their primary role is to wipe excess oil off the cylinder walls as the piston moves up and down. By doing so, they ensure that only a precise amount of oil reaches the combustion chamber.

Importance of Oil Wiper Rings

The importance of oil wiper rings can be understood better by looking at several critical functions they perform

1. Reducing Oil Consumption One of the primary functions of oil wiper rings is to minimize oil consumption in engines. Excess oil can lead to incomplete combustion, which not only reduces engine efficiency but also increases emissions. Effective oil wiper rings ensure that only the necessary amount of oil is used, thereby promoting better fuel economy.

2. Preventing Oil Leakage Oil wiper rings also play a vital role in preventing oil from leaking into other areas of the engine where it doesn't belong. This helps maintain the overall integrity of the engine and prevents damage that could arise from oil being present in areas like the combustion chamber.

3. Enhancing Lubrication By controlling the amount of oil that reaches different engine components, oil wiper rings ensure that critical parts such as pistons, crankshafts, and valves are adequately lubricated. Proper lubrication is essential for reducing friction and wear, thereby extending the lifespan of the engine parts.

4. Controlling Emissions With stricter environmental regulations in place, controlling emissions has become more critical than ever. Efficient oil wiper rings help reduce the amount of unburned oil entering the exhaust system, which minimizes harmful emissions. This is particularly important for compliance with regulations and for promoting a greener environment.

Working Mechanism of Oil Wiper Rings

oil wiper ring

Oil wiper rings are typically made of durable materials that can withstand the harsh conditions found within an engine. The design of the rings usually incorporates specific profiles and gaps that allow for optimal oil control. As the piston moves up, the ring scrapes excess oil off the cylinder wall, ensuring that only a thin film is left to lubricate the moving parts.

One key aspect of their design is the multi-piece construction of some oil wiper rings, which can enhance their effectiveness. These rings may consist of an outer ring, a wiper band, and sometimes a spring that helps maintain tension against the cylinder wall. This multi-part design is crucial for providing flexibility and adaptability, allowing the rings to work effectively even as parts wear over time.

Applications of Oil Wiper Rings

Oil wiper rings are employed across a myriad of applications, including

- Automotive Engines In cars and trucks, they are essential for maintaining engine performance, improving fuel efficiency, and reducing emissions.

- Industrial Machinery Heavy machinery used in construction, manufacturing, and agriculture rely on efficient oil wiper rings to operate smoothly and minimize downtime due to repairs.

- Marine Engines Boats and ships utilize oil wiper rings to ensure engines remain lubricated and efficient during long journeys.

- Power Generators Backup generators and large power plants depend on reliable oil wiper rings to maintain engine functionality and optimize energy production.

Conclusion

Oil wiper rings are more than just minor components; they play a pivotal role in the efficiency and longevity of engines and machinery. Understanding their functions, importance, and applications is crucial for anyone involved in mechanical engineering, automotive maintenance, or related fields. As technology advances, the design and materials used in oil wiper rings will continue to evolve, further enhancing their functionality and performance in the coming years.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories