Feb . 16, 2025 01:15 Back to list

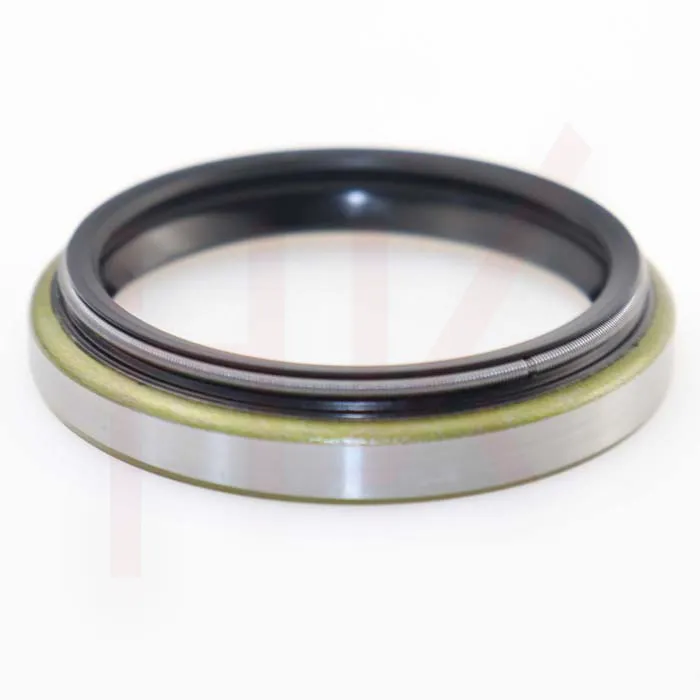

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

In the industrial world, the pivotal role of hydraulic and pneumatic systems is often overshadowed by larger machinery components, yet these systems cannot function efficiently without one unassuming but critical component the seal kit cylinder. Understanding seal kit cylinders is essential if you are involved in industries such as construction, manufacturing, or automotive sectors where hydraulic systems are a daily necessity.

For those contemplating the purchase of seal kit cylinders, the market offers a plethora of options that require scrutiny not only for the seal suitability but also for the reputation of manufacturers. Authoritative and trustworthy brands usually offer extensive warranties and have a track record of rigorous testing to ensure their products meet the industry’s highest standards. These assurances make a significant difference in long-term operational success. Businesses that utilize seal kit cylinders cannot overlook the necessity of regular maintenance checks. A frequent review routine ensures that any wear and tear is identified before it becomes problematic. Deploying monitoring devices to track seal integrity can prevent unforeseen system failures, thereby increasing operational trustworthiness. Lastly, in today's eco-conscious industry landscape, the disposal and recycling of worn-out seal materials factor into the decision-making process. Companies striving for sustainability should consider manufacturers that implement green practices, such as offering recyclable products or take-back programs, transforming a required purchase into an environmentally responsible action. In conclusion, understanding the intricacies of seal kit cylinders is not merely an operational concern; it also reflects a company’s commitment to quality, efficiency, and sustainability. Companies that prioritize expertise in the selection and maintenance of seal kit cylinders place themselves at a competitive advantage, ensuring reliability and excellence in their production capabilities. Seal kit cylinders, while minute components, are foundational to the seamless function of the larger industrial mechanism.

For those contemplating the purchase of seal kit cylinders, the market offers a plethora of options that require scrutiny not only for the seal suitability but also for the reputation of manufacturers. Authoritative and trustworthy brands usually offer extensive warranties and have a track record of rigorous testing to ensure their products meet the industry’s highest standards. These assurances make a significant difference in long-term operational success. Businesses that utilize seal kit cylinders cannot overlook the necessity of regular maintenance checks. A frequent review routine ensures that any wear and tear is identified before it becomes problematic. Deploying monitoring devices to track seal integrity can prevent unforeseen system failures, thereby increasing operational trustworthiness. Lastly, in today's eco-conscious industry landscape, the disposal and recycling of worn-out seal materials factor into the decision-making process. Companies striving for sustainability should consider manufacturers that implement green practices, such as offering recyclable products or take-back programs, transforming a required purchase into an environmentally responsible action. In conclusion, understanding the intricacies of seal kit cylinders is not merely an operational concern; it also reflects a company’s commitment to quality, efficiency, and sustainability. Companies that prioritize expertise in the selection and maintenance of seal kit cylinders place themselves at a competitive advantage, ensuring reliability and excellence in their production capabilities. Seal kit cylinders, while minute components, are foundational to the seamless function of the larger industrial mechanism.

Latest news

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories