Oct . 13, 2024 14:41 Back to list

Hydraulic Seal Maintenance and Repair Kit for Efficient Equipment Performance

Understanding Hydraulic Seal Repair Kits Essential Tools for Maintenance

Hydraulic systems are integral components in various machinery and vehicles, providing the power necessary to perform tasks efficiently and effectively. From construction equipment to manufacturing machinery, these systems rely on hydraulics to function smoothly. However, like any mechanical system, hydraulic components are susceptible to wear and tear, which can lead to leaks and failures. This is where hydraulic seal repair kits come into play, offering a practical solution for maintenance and repair.

What Is a Hydraulic Seal Repair Kit?

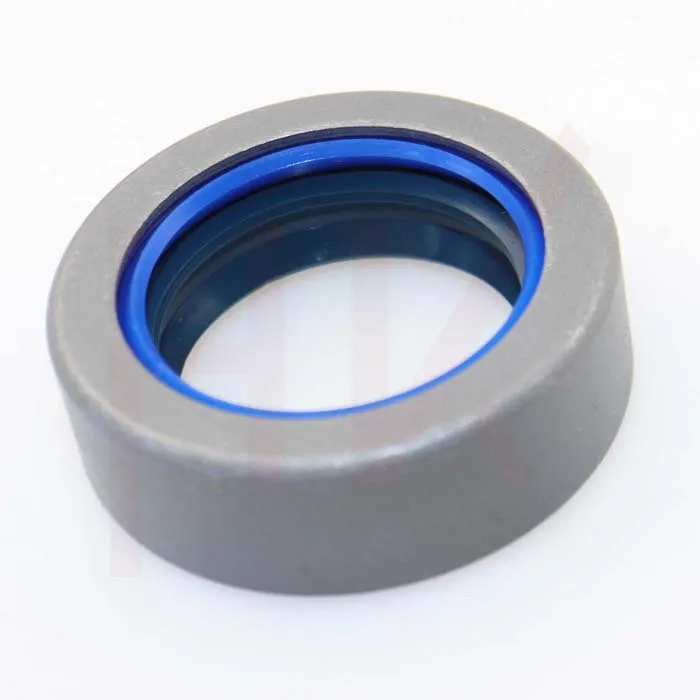

A hydraulic seal repair kit is a collection of tools and components designed to replace or repair seals in hydraulic systems. These seals are critical for preventing fluid leaks and maintaining the system's pressure. When seals wear out or become damaged due to friction, high pressure, or exposure to harsh chemicals, the efficiency of the hydraulic system can decline significantly, leading to potential malfunction.

Typically, a hydraulic seal repair kit includes various O-rings, seals, and other related components. The exact contents can vary based on the specific application or machine for which the kit is designed. Some kits may also come with additional tools, such as seal pullers or installation guides, to assist in the repair process.

Why Use a Hydraulic Seal Repair Kit?

1. Cost-Effective Solution Repairing hydraulic seals with a dedicated kit can be significantly cheaper than replacing entire hydraulic cylinders or other components. This can lead to substantial cost savings in equipment maintenance and downtime.

2. Improved Efficiency Regular maintenance of hydraulic systems through seal repairs can improve efficiency and performance. By addressing leaks and ensuring that seals are functioning correctly, machinery can operate at optimal capacity.

3. Convenience Having a hydraulic seal repair kit on hand allows for quick repairs. This convenience reduces downtime and helps maintain productivity.

hydraulic seal repair kit

How to Use a Hydraulic Seal Repair Kit

Using a hydraulic seal repair kit requires some basic mechanical knowledge, but it can often be completed as a straightforward task. Here is a general guide on how to go about it

1. Identify the Problem Examine the hydraulic system to locate the source of the leak. Make sure to diagnose the exact component that needs attention—whether it’s a cylinder, pump, or other assembly.

2. Disassemble the Unit Safely remove the component that houses the seals. Ensure that the system is depressurized before starting any disassembly to prevent injury and further damage.

3. Remove Old Seals Carefully extract the old seals and O-rings from their grooves. This may require specialized tools, especially if the seals are stuck.

4. Clean the Component Thoroughly clean the area where the seals were housed. Remove any debris, old seal material, and hydraulic fluid to ensure a proper seal installation.

5. Install New Seals Select the appropriate new seals from your repair kit, and install them according to the manufacturer’s guidelines. Be cautious not to twist or damage the seals during installation.

6. Reassemble and Test After replacing the seals, carefully reassemble the hydraulic unit. Ensure all components are secured properly, then test the system to check for leaks and confirm that it functions as intended.

Conclusion

Hydraulic seal repair kits are vital for maintaining the integrity and performance of hydraulic systems. By equipping oneself with the right tools and knowledge, operators and maintenance technicians can effectively address leaks and extend the life of their hydraulic components. Regularly scheduled maintenance and timely repairs not only enhance machine efficiency but also contribute to safer and more reliable operations across industries. Whether you are a professional mechanic or a do-it-yourself homeowner, having a hydraulic seal repair kit on hand is an investment in the longevity of your hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories