Sep . 24, 2024 22:27 Back to list

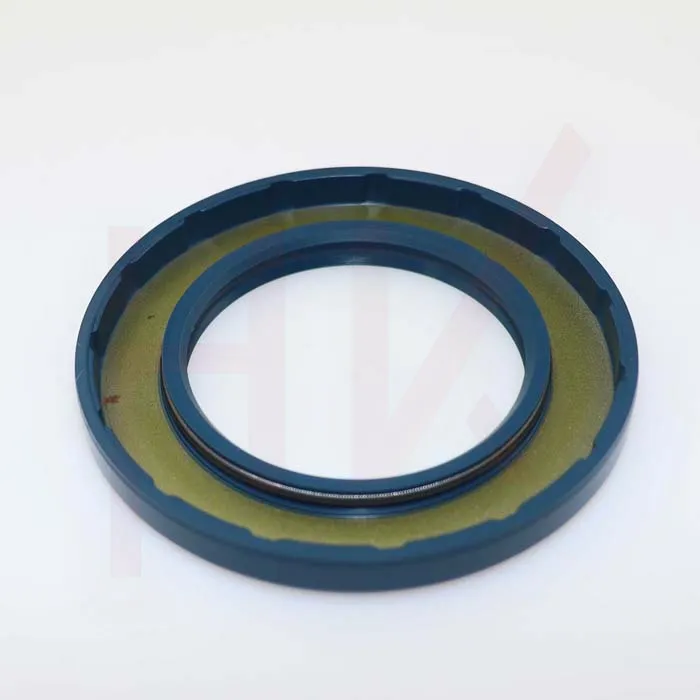

hub grease seal

Understanding Hub Grease Seals Importance and Maintenance

In the world of mechanical engineering and maintenance, the hub grease seal plays a crucial role in ensuring the longevity and efficiency of various machinery and vehicles. This seemingly small component is vital for preventing the ingress of contaminants into the bearing areas, thus safeguarding the intricate mechanisms that define performance.

Definition and Function

A hub grease seal, often found in wheel hubs, axles, and various other machinery components, is designed to retain lubricants while keeping out dirt, water, and other impurities. Typically made from rubber or synthetic materials, these seals form a barrier that protects the internal components from environmental factors. The effective functioning of a hub grease seal contributes significantly to the overall mechanical health of the system, helping to prevent premature wear and potential failures.

Importance of Hub Grease Seals

1. Contaminant Protection One of the primary roles of a grease seal is to block dust, dirt, and moisture from entering the bearing assembly. Contaminants can lead to corrosion and can drastically shorten the life of the bearings within the hub.

2. Lubricant Retention Hub grease seals ensure that the grease used to lubricate bearings stays contained within the hub. Proper lubrication minimizes friction, reduces wear, and ultimately extends the lifespan of the bearings.

3. Operational Efficiency With contaminants kept at bay and lubrication properly maintained, machinery can run more smoothly and efficiently. This leads to better performance and can result in lower operating costs over time.

4. Safety Considerations In vehicles, faulty grease seals can lead to bigger issues, such as brake failure, which can compromise safety. Maintaining effective hub grease seals is essential for ensuring both vehicle and operator safety.

Signs of a Failing Hub Grease Seal

Over time, even the best hub grease seals can wear out or become damaged. Recognizing the early signs of failure can be crucial in preventing more significant issues down the line. Here are some signs that a hub grease seal may need attention

hub grease seal

- Leakage One of the most obvious signs is the presence of grease or oil leaking from the hub. If you notice any fluid on the ground beneath your vehicle, it might indicate a seal failure.

- Noise Unusual sounds coming from the wheel area, such as grinding or whining, can indicate inadequate lubrication due to a failing grease seal. This noise suggests that the bearings are not receiving proper lubrication.

- Overheating If the hubs are running hotter than usual, it might be a result of friction caused by contamination or inadequate lubrication.

Maintenance of Hub Grease Seals

To ensure the longevity and effectiveness of hub grease seals, regular inspection and maintenance are vital. Here are some steps to follow

1. Regular Inspections Check for signs of wear or damage during routine maintenance. Look for cracks or tears in the seals, as well as any leakage around the hub.

2. Proper Lubrication Ensure that the grease used is suitable for the environment and compatible with the seals. Over-greasing can lead to seal failure, while under-greasing can lead to rapid wear.

3. Replacement If a seal shows significant wear or if there are signs of leakage, it should be replaced promptly to prevent further damage. Always use seals that meet manufacturer specifications.

4. Environmental Considerations In harsh environments, such as those with high levels of dust or water exposure, more frequent maintenance checks may be needed.

Conclusion

The hub grease seal may seem like a small and unassuming component, yet its importance cannot be overstated. By understanding its function and purpose, recognizing the signs of failure, and adhering to a diligent maintenance plan, individuals and organizations can enhance the durability and performance of their machinery. In a world where efficiency and reliability are key, paying attention to such details is essential for long-term success and safety.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories