Sep . 19, 2024 22:33 Back to list

50x90x10 oil seal

Understanding the 50x90x10 Oil Seal A Key Component in Mechanical Applications

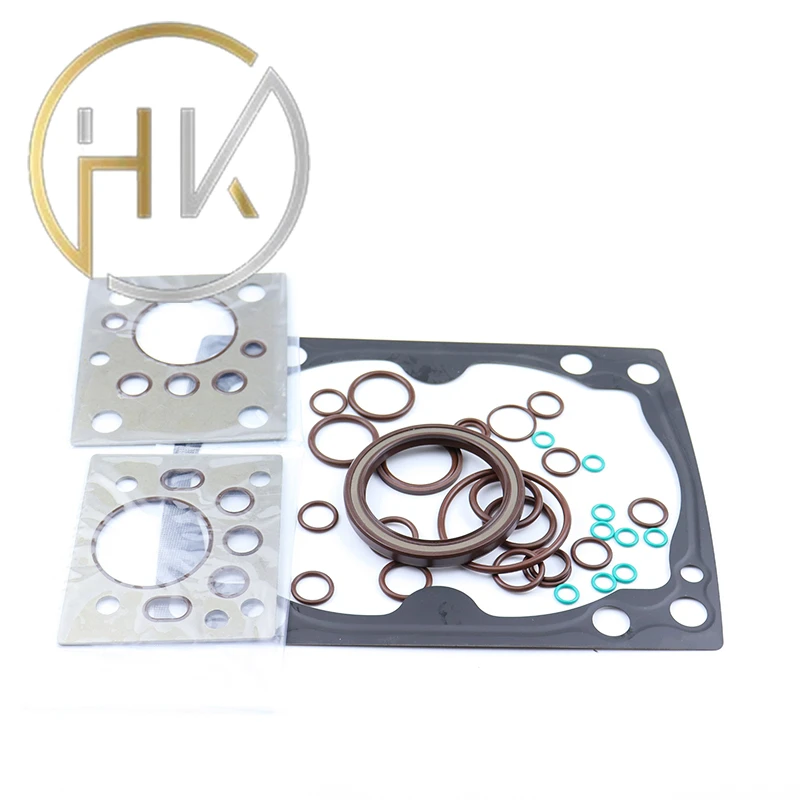

In the realm of mechanical engineering, oil seals play a crucial role in ensuring the efficiency and longevity of machinery. One specific type of oil seal that has gained attention is the 50x90x10 oil seal. This component is essential for various applications, including automotive, industrial machinery, and hydraulic systems. Understanding its dimensions and functionality can enhance the reliability of equipment and reduce maintenance costs.

Understanding the 50x90x10 Oil Seal A Key Component in Mechanical Applications

The percentage 20 likely refers to the material composition or the specific design variation pertinent to the sealing application. Oil seals are often made from rubber or synthetic materials, engineered to withstand harsh conditions such as extreme temperatures and exposure to various fluids. For the 50x90x10 oil seal, the might denote a particular formulation of the seal material that enhances its resistance to wear and enhances its sealing capabilities.

50x90x10 oil seal

Oil seals function primarily to prevent the leakage of lubricants while preventing contaminants, such as dirt and dust, from entering sensitive areas of machinery. In engines, they play a pivotal role in maintaining lubrication within the crankshaft and camshaft areas. This sealing capability is crucial as it helps maintain optimal performance, enhances fuel efficiency, and prolongs component life.

In addition to preventing leaks and contaminants, the design of an oil seal like the 50x90x10 may include features such as a lip or a spring that exerts pressure against the rotating shaft, enhancing the seal’s effectiveness. This design consideration is essential in high-speed applications, where the centrifugal force can otherwise compromise the seal's integrity.

Regular maintenance and timely replacement of oil seals are critical for equipment performance. Over time, oil seals may degrade due to heat, friction, or exposure to harsh chemicals, leading to potential failures. Therefore, understanding the specifications of components such as the 50x90x10 oil seal is important for engineers and technicians involved in machinery upkeep.

In conclusion, the 50x90x10 oil seal is a fundamental component in mechanical systems, valued for its ability to maintain lubrication and protect machinery from contaminants. By ensuring proper selection and maintenance, professionals can significantly enhance the performance and reliability of mechanical equipment, ultimately contributing to greater operational efficiency and reduced downtime. Understanding and utilizing the right oil seal is not just a matter of necessity; it’s a strategy for sustaining productivity in an ever-demanding industrial landscape.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories