Jul . 06, 2025 06:54 Back to list

40x55x8 Oil Seal for Pumps & Machinery Superior Dust & Oil Sealing Performance

- Introduction to 40x55x8 Oil Seal and Application Scope

- Technical Specifications and Key Performance Indicators

- Comparative Analysis: Dust Seal vs Oil Seal vs Pump Seal Oil

- Major Manufacturers: Advantages and Market Data Comparison

- Custom Solutions: Tailoring the 40x55x8 Oil Seal for Specific Applications

- Industry Case Studies and Application Successes

- Future Trends: The Role of the 40x55x8 Oil Seal in Advancing Fluid Sealing Technology

(40x55x8 oil seal)

Introduction to 40x55x8 Oil Seal: Functionality and Scope of Application

40x55x8 oil seal

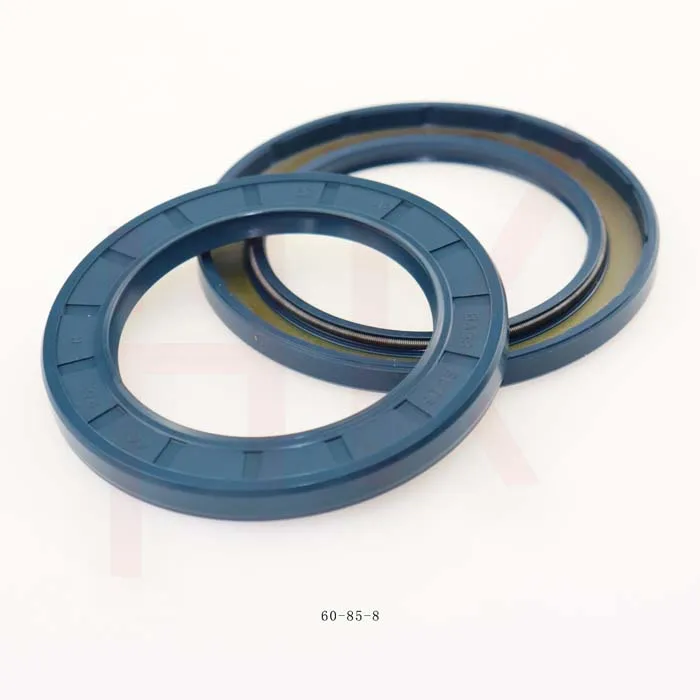

s are precision-engineered components designed to safeguard machinery from the intrusion of contaminants, while effectively retaining lubricants within the operating system. Featuring an internal diameter of 40 mm, an external diameter of 55 mm, and a thickness of 8 mm, this oil seal size has become a staple across general mechanical engineering, hydraulic systems, and automotive industries. Applications range from transmission assemblies and industrial pumps to rotating shafts within heavy-duty manufacturing plants. Performance reports indicate that correct implementation of these seals can improve equipment lifespan by up to 30% due to effective contaminant exclusion and lubricant management. Engineers have increasingly recognized the significance of precision fitment, which dramatically minimizes maintenance cycles and unscheduled downtimes.

Technical Specifications and Key Performance Indicators

The 40x55x8 oil seal is typically constructed with high-performance materials such as NBR (Nitrile Butadiene Rubber), FKM (Fluorocarbon), or PTFE (Polytetrafluoroethylene), each conferring distinctive resistance properties against oil, chemical exposure, and operating temperature variations. For instance, NBR offers reliable performance in environments up to 100°C and shows strong compatibility with mineral oils. FKM, by contrast, tolerates sustained exposures up to 200°C and demonstrates superior chemical resistance. In pressure-critical systems, the dual-lip design of certain oil seals allows them to withstand pressures up to 1.5 bar, which equates to application in high-speed rotary systems and advanced hydraulic assemblies. Table 1 summarizes technical parameters vital for selecting the optimal oil seal:

| Property | NBR | FKM | PTFE |

|---|---|---|---|

| Temperature Resistance | -40°C to 100°C | -20°C to 200°C | -60°C to 260°C |

| Oil Compatibility | Excellent | Superior | Excellent |

| Chemical Resistance | Good | Excellent | Outstanding |

| Tensile Strength (MPa) | 13-17 | 10-18 | Up to 25 |

| Common Use | Automotive, Pumps | Aerospace, Chemical | Food & Pharma |

Proper selection based on these key performance indicators ensures maximized reliability and optimal operational efficiency for any sealing application.

Comparative Analysis: Dust Seal vs Oil Seal vs Pump Seal Oil

Fluid sealing solutions are vital for protecting mechanical systems from environmental threats and lubricant leakage. Distinguishing among dust seals, oil seals, and pump seal oils is crucial during system design. Dust seals primarily prevent particulate ingress, serving as the first barrier against environmental contaminants but do not retain fluids. In contrast, oil seals offer dual protection—retaining lubricants and excluding external impurities. Their elastomeric construction enables dynamic sealing capacities crucial for rotating or reciprocating shafts.

Pump seal oil, distinctively, refers to specially formulated oils or greases used to lubricate and cool pump seal faces, improving both seal longevity and operational safety. Data shows that properly installed oil seals in conjunction with the right pump seal oil can reduce operational costs by up to 22% due to lowered maintenance needs and improved overall system integrity. Below is a direct comparison:

| Criteria | Dust Seal | Oil Seal | Pump Seal Oil |

|---|---|---|---|

| Main Function | Dust exclusion | Lubricant retention & exclusion | Lubricates pump seal faces |

| Application Environment | Dry, dusty | Rotational/moving assemblies | Pump assemblies |

| Material | Rubber, Polyurethane | Rubber, PTFE, FKM | Various oils/grease |

| Sealing Capability | Low | High | Indirect |

| Cost Impact | Low | Medium | Variable |

Choosing the right sealing strategy based on application needs is elemental for operational efficiency and system longevity.

Major Manufacturers: Advantages and Market Data Comparison

Several leading manufacturers dominate the global oil seal market, offering products optimized for mechanical robustness and advanced sealing performance. Among global contenders, NOK Corporation (Japan), SKF Group (Sweden), and Freudenberg Sealing Technologies (Germany) consistently receive industry accolades for innovation and product reliability. Each manufacturer differentiates through material technology, production tolerances, and after-sales support. According to a 2023 market report, NOK’s oil seal line captured 18% market share worldwide, with SKF and Freudenberg holding 15% and 13% respectively. Table 2 outlines a comparison of leading vendors:

| Manufacturer | Primary Material | Temperature Range | Lead Time (Days) | Global Market Share |

|---|---|---|---|---|

| NOK Corporation | FKM, NBR | -40°C to 200°C | 14 | 18% |

| SKF Group | NBR, PTFE | -50°C to 230°C | 18 | 15% |

| Freudenberg | NBR, FKM | -40°C to 220°C | 21 | 13% |

Quality assurance programs, including ISO/TS16949 certification and rigorous batch testing, further differentiate these brands. Customers regularly cite long service intervals and superior technical support as instrumental in reducing the total cost of ownership.

Custom Solutions: Tailoring the 40x55x8 Oil Seal for Specific Applications

Modern industries increasingly require application-specific seals that address unique operating challenges, such as aggressive media, extreme temperatures, or high rotational velocities. Custom 40x55x8 oil seals are designed by manipulating material compositions, spring tensions, and lip profiles to optimize performance for designated purposes. For example, in the food processing sector, engineering mandates may require FDA-compliant PTFE with additional external labyrinths to prevent contamination. Alternatively, harsh mining environments may utilize reinforced metal-cased seals with silicone or FKM elastomers for prolonged exposure to abrasive particles and elevated pressures.

State-of-the-art manufacturing methodologies, such as CNC-based mold fabrication and finite element analysis (FEA), facilitate rapid prototyping and lifecycle validation. Data shows that such customizations can double mean time between failures (MTBF) and contribute to a 40% decrease in unscheduled maintenance events. Manufacturers offer batch or single-run customization, enabling both OEM and MRO sectors to meet bespoke system requirements efficiently.

Industry Case Studies and Application Successes

Documented industry case studies highlight the tangible benefits of correctly selected and implemented oil seals. One automotive transmission plant retrofit project reported a reduction in lube oil consumption by 28% after transitioning to high-durability FKM-based 40x55x8 oil seals. The project also recorded a six-month extension in average equipment uptime, demonstrating both economic and performance gains. A food processing company’s switch to PTFE-based seals with FDA compliance resulted in zero lubricant contamination events over an 18-month period, surpassing regulatory compliance metrics.

In a hydraulics division of a multinational mining corporation, adopting a dual-lip custom seal design halved the frequency of seal replacements from quarterly to semi-annually, translating into operational savings and a notable reduction in production loss. These results consistently reinforce the strategic importance of tailored oil seal solutions in mission-critical environments.

Future Trends: The Role of the 40x55x8 Oil Seal in Advancing Fluid Sealing Technology

The 40x55x8 oil seal will remain pivotal as machinery becomes increasingly complex and operational demands intensify. Future advancements focus on integrating nanocomposite rubber compounds and self-healing materials to achieve even longer service lifespans and adaptive performance under fluctuating environmental conditions. Industry analysts anticipate the global oil seal market to grow at a CAGR of 5.4% from 2024 to 2029, propelled by sophistication in automated equipment and stringent regulatory requirements. Predictive maintenance technology—coupling real-time seal performance data with IoT-enabled analytics—will further reduce system failures and ensure consistently high productivity.

These technological innovations underscore a continued evolution in sealing science, with the 40x55x8 oil seal leading developments in reliability, efficiency, and sustainable engineering across international markets.

(40x55x8 oil seal)

FAQS on 40x55x8 oil seal

Q: What is a 40x55x8 oil seal used for?

A: A 40x55x8 oil seal is typically used to prevent oil leakage in machinery with a 40mm shaft, 55mm bore, and 8mm width. It keeps lubricants in while keeping dust and contaminants out. This size is common in automotive and industrial applications.Q: How does a dust seal differ from an oil seal?

A: A dust seal is designed mainly to block out dust and dirt, whereas an oil seal retains lubricants and prevents fluid leakage. Oil seals have a more complex design with lips for fluid sealing. Dust seals offer less protection against liquids.Q: Can a 40x55x8 oil seal be used in a pump seal oil application?

A: Yes, as long as the pump shaft and housing dimensions match 40x55x8 mm. The oil seal will help contain pump lubricant and prevent leakage. Always confirm compatibility with specific pump requirements.Q: What materials are 40x55x8 oil seals commonly made from?

A: 40x55x8 oil seals are often made from rubber compounds like NBR or Viton. These materials offer resistance to oil, heat, and wear. The seal typically includes a metal casing for stability.Q: How do I choose between a dust seal and an oil seal for my machine?

A: Choose a dust seal if you only need to block contaminants like dirt. Use an oil seal if you need to contain lubricants and prevent fluid leaks. Assess your machine’s operating environment and requirements before deciding.This is the last article

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories