stu . 26, 2024 07:15 Back to list

Hydraulic Seal Kits for Enhanced Performance and Durability in Machinery Applications

The Importance and Functionality of Seal Kits in Hydraulic Systems

Hydraulic systems are integral to a multitude of modern industries, from manufacturing and transportation to construction and agriculture. One of the key components that contribute to the performance and reliability of these systems is the seal kit. A hydraulic seal kit is designed to prevent fluid leakages, maintain pressure, and ensure smooth operation of hydraulic machinery and components. In this article, we will explore the importance of seal kits, their composition, types, and the factors that lead to their wear and tear.

Understanding Seal Kits in Hydraulic Systems

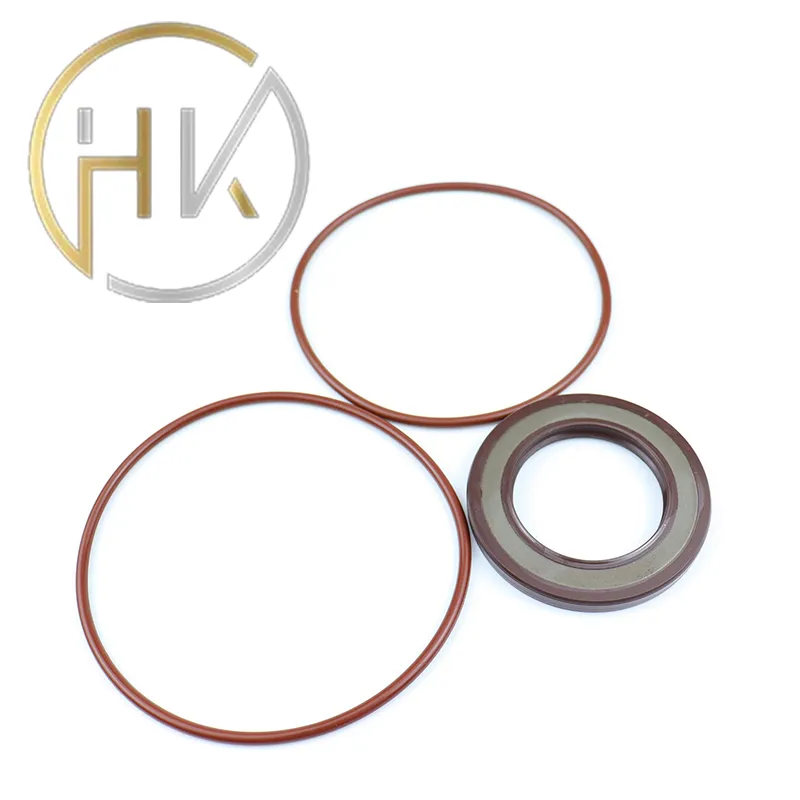

At the core of a hydraulic system, the mechanics work by using pressurized fluid to perform tasks like lifting, pushing, or rotating. The effectiveness of this system hinges on the integrity of the seals that keep the hydraulic fluid contained. Seal kits typically include various sealing elements such as O-rings, backup rings, gaskets, and rod seals, all tailored to specific applications. These components fit into different parts of the hydraulic assembly, including cylinders, pumps, and motors, where they effectively seal off the high-pressure fluid.

Components of a Hydraulic Seal Kit

1. O-Rings These circular seals are one of the most common sealing components. They are made from materials such as rubber, nitrile, or polyurethanes, and their design allows them to fit snugly into grooves, creating a tight seal with minimal leakage.

2. Backup Rings Typically used in conjunction with O-rings, backup rings support the O-rings in high-pressure applications. They prevent the O-rings from extruding under pressure, thereby enhancing the lifespan and effectiveness of the seal.

3. Rod Seals Essential for hydraulic cylinders, these seals prevent fluid from leaking along the rod as it moves in and out of the cylinder. They are critical for maintaining efficiency and pressure within the system.

4. Gaskets Often used to fill the space between two or more mating surfaces, gaskets are vital for ensuring a leak-proof seal in flanged joints.

5. U-Cups These are specially designed seals, often used in various hydraulic cylinders, to provide a good sealing action in both dynamic and static applications.

Types of Hydraulic Seal Kits

Hydraulic seal kits can be classified based on several factors

seal kit hydraulic

- Application Type Various industries and applications require specific seal kits tailored to unique operating environments. Kits may be designed for heavy machinery, aerospace, marine applications, or general industrial use.

- Material Composition Seal kits can be made from different materials, including elastomers like nitrile, which offer resilience against petroleum-based fluids, or fluorocarbon, which provides excellent performance in extreme temperatures and harsh environments.

- Sizing Seal kits are available in various sizes to fit different hydraulic components, ensuring that there is a suitable option for virtually every hydraulic application

.Causes of Seal Wear and Tear

Despite their robust design and functionality, hydraulic seals are susceptible to wear due to several factors

1. Contamination Dirt, dust, and foreign particles can compromise the integrity of seals, leading to premature failure.

2. Temperature Extremes Seals are sensitive to temperature variations; excessive heat can cause them to degrade, while extreme cold can lead to brittleness.

3. Pressure Fluctuations Sudden pressure spikes can force seals to their limits, resulting in failure.

4. Chemical Exposure Exposure to incompatible fluids can weaken seal materials, causing leaks and functional issues.

5. Mechanical Misalignment Proper installation is crucial. Misalignment can lead to uneven wear and premature seal failure.

Conclusion

The importance of seal kits in hydraulic systems cannot be overstated. They play a vital role in ensuring that hydraulic equipment operates efficiently and reliably. Regular maintenance, assessment of operating conditions, and timely replacement of worn seal kits are essential practices to prolong the life of hydraulic systems. Investing in quality seal kits and understanding their functionalities can lead to enhanced productivity, reduced downtime, and significant cost savings in hydraulic operations. As industries evolve, the development and innovation in seal kit technology will continue to play a crucial role in the future of hydraulic engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories