stu . 16, 2024 07:34 Back to list

hydraulic cylinder kits repair

Understanding Hydraulic Cylinder Kits Repair A Comprehensive Guide

Hydraulic cylinders are essential components used in various machinery and equipment, from construction vehicles to manufacturing machinery. These cylinders convert hydraulic energy into mechanical energy, allowing for powerful lifting and movement. However, like any mechanical system, hydraulic cylinders can experience wear and tear, leading to the need for repair. This is where hydraulic cylinder kits come into play. In this article, we will explore the importance of hydraulic cylinder repair kits, the components they include, and the repair process itself.

Importance of Hydraulic Cylinder Repair

Hydraulic cylinders face significant stress and potential damage due to constant use. Factors such as high pressure, temperature variations, and environmental exposure can cause seals to fail, rods to bend, or even the cylinder itself to corrode. When a hydraulic cylinder fails, it can lead to decreased operational efficiency, increased downtime, and costly repairs. Therefore, regular maintenance and timely repairs are crucial for ensuring the longevity and performance of hydraulic systems.

What are Hydraulic Cylinder Repair Kits?

Hydraulic cylinder repair kits are specially designed packages that contain all the necessary components needed to repair a hydraulic cylinder. These kits are available for various types, sizes, and brands of hydraulic cylinders, making it easier for operators to perform repairs without the need for extensive tools or technical knowledge.

The components included in a typical hydraulic cylinder repair kit may vary, but they generally consist of

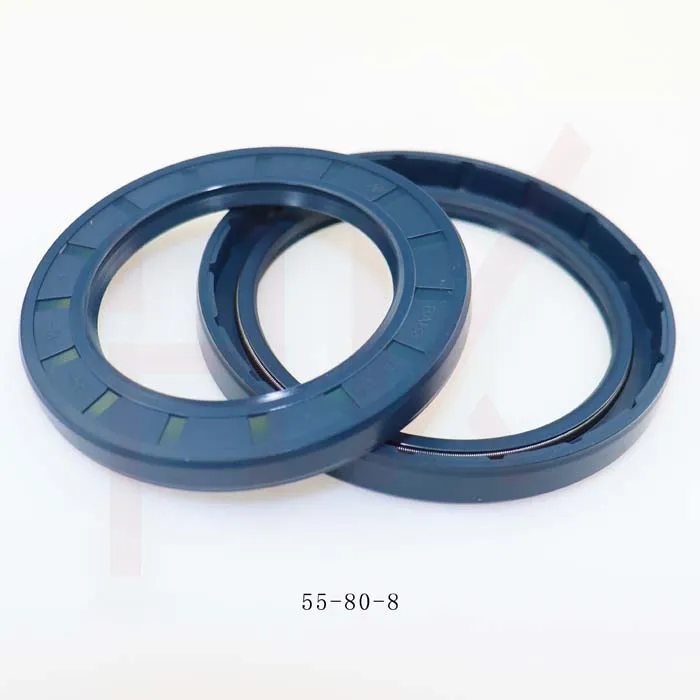

1. Seals and O-Rings These are critical components that prevent hydraulic fluid from leaking. The seals create a tight seal between the cylinder and the piston, while O-rings are used in various joints throughout the cylinder.

2. Piston Kits A piston kit might include the piston itself and any accompanying components that may need replacement.

3. Rod Bearings These components support the hydraulic cylinder rod and ensure smooth movement while minimizing wear.

hydraulic cylinder kits repair

5. Instruction Manual Most kits come with a detailed manual that outlines the repair process, tools required, and safety precautions.

The Repair Process

Performing a hydraulic cylinder repair can seem daunting, but with the right tools and a clear understanding of the process, it can be accomplished efficiently. Here’s a step-by-step guide for repairing a hydraulic cylinder using a repair kit

1. Preparation Before you begin, ensure that you have a clean workspace. Gather all the necessary tools, which may include wrenches, screwdrivers, a hydraulic press (optional), and safety gear.

2. Disassembly Carefully remove the hydraulic cylinder from the machine. Drain the hydraulic fluid to prevent spills. Take note of how the cylinder is assembled, as you will need to reassemble it later.

3. Inspection Examine all components for signs of damage, including the cylinder tube, piston, and rod. Look for scratches, corrosion, and signs of wear. Knowing what needs to be replaced is key to effective repairs.

4. Replace Worn Components Use the components from the hydraulic cylinder repair kit to replace all worn-out parts. Begin by installing new seals and O-rings, ensuring they fit snugly in their respective grooves.

5. Reassemble the Cylinder Once all the necessary replacements have been made, reassemble the hydraulic cylinder carefully. Follow the notes you made during disassembly to ensure everything is put back correctly.

6. Testing After reassembling, reattach the hydraulic cylinder to the machine and refill it with hydraulic fluid. Test the system to ensure that the cylinder operates smoothly without any leaks.

Conclusion

Hydraulic cylinder repair kits are invaluable tools for maintaining the efficiency and longevity of hydraulic systems. By understanding the components of these kits and following a systematic repair process, operators can save time and reduce costs associated with hydraulic cylinder failures. Regular maintenance, combined with timely repairs, can help keep various machinery and equipment running smoothly, ultimately enhancing productivity and safety in the workplace.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories